Zero sequence current mutual inductor

A zero-sequence current, transformer technology, applied in the direction of inductors, transformers/inductor coils/windings/connections, voltage/current isolation, etc., can solve the scratching damage of insulating tapes, the difficulty of conducting copper bars, and the difficulty of wearing transformers It can save space, shorten working hours, and avoid passing through and arranging processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

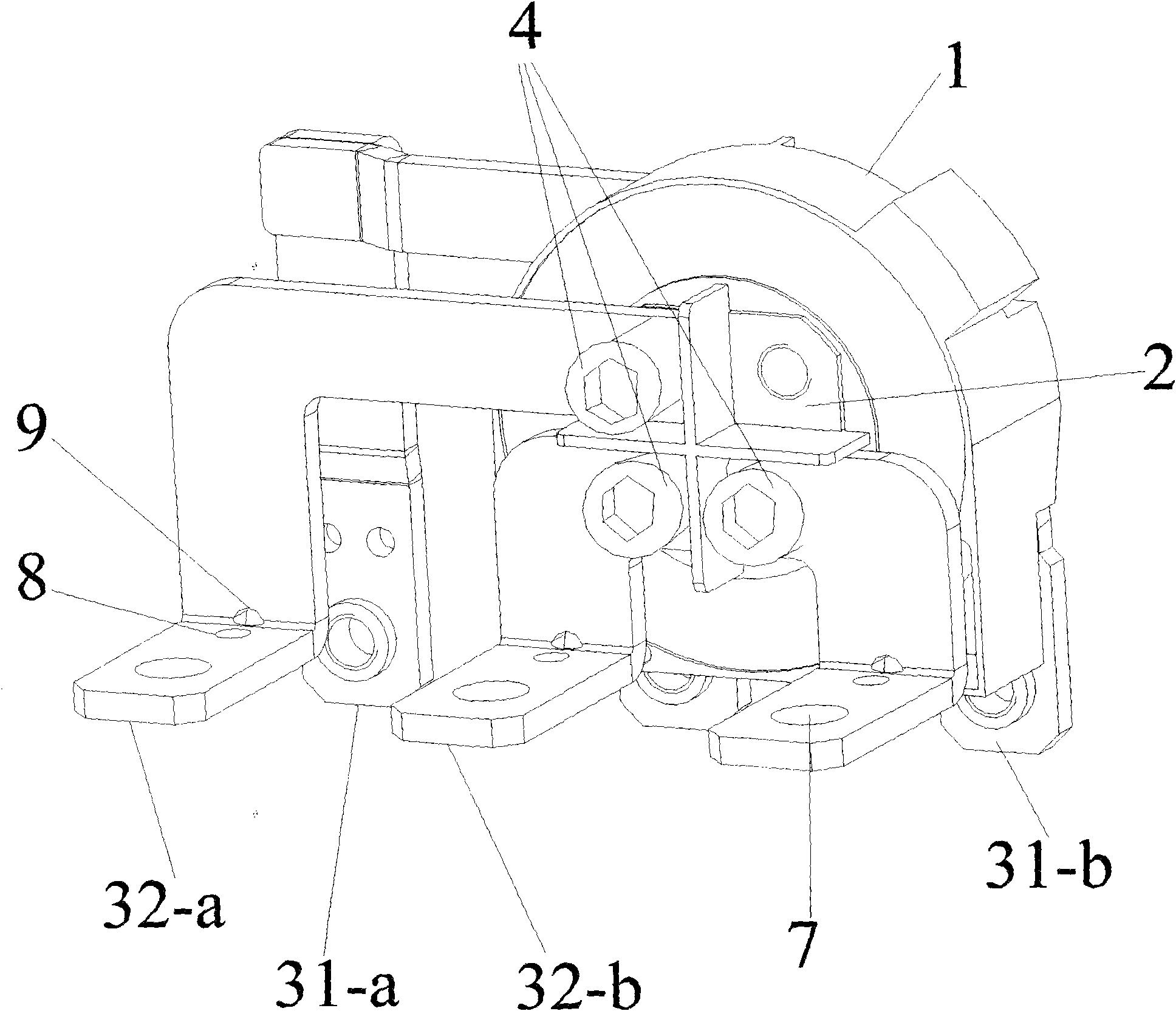

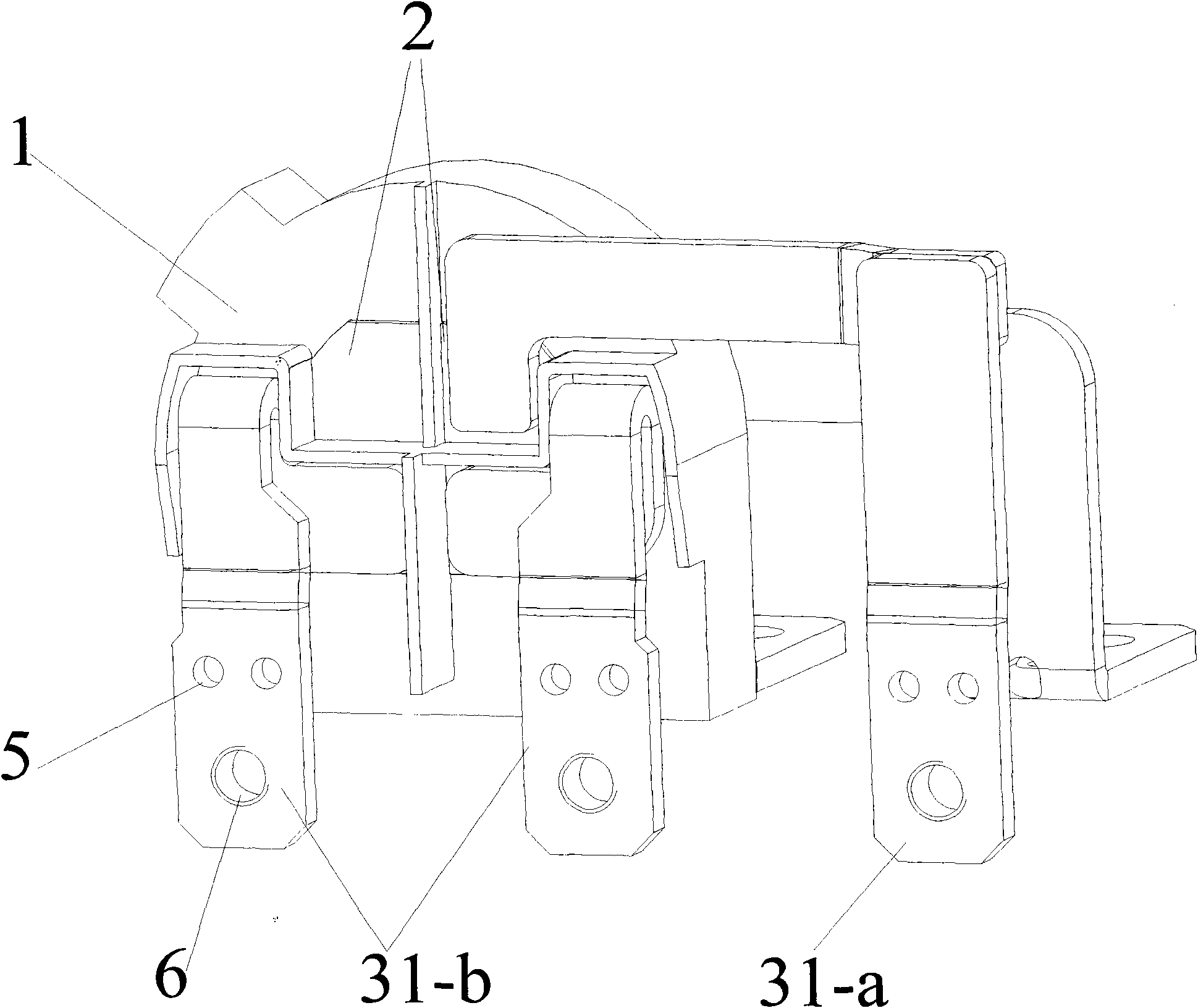

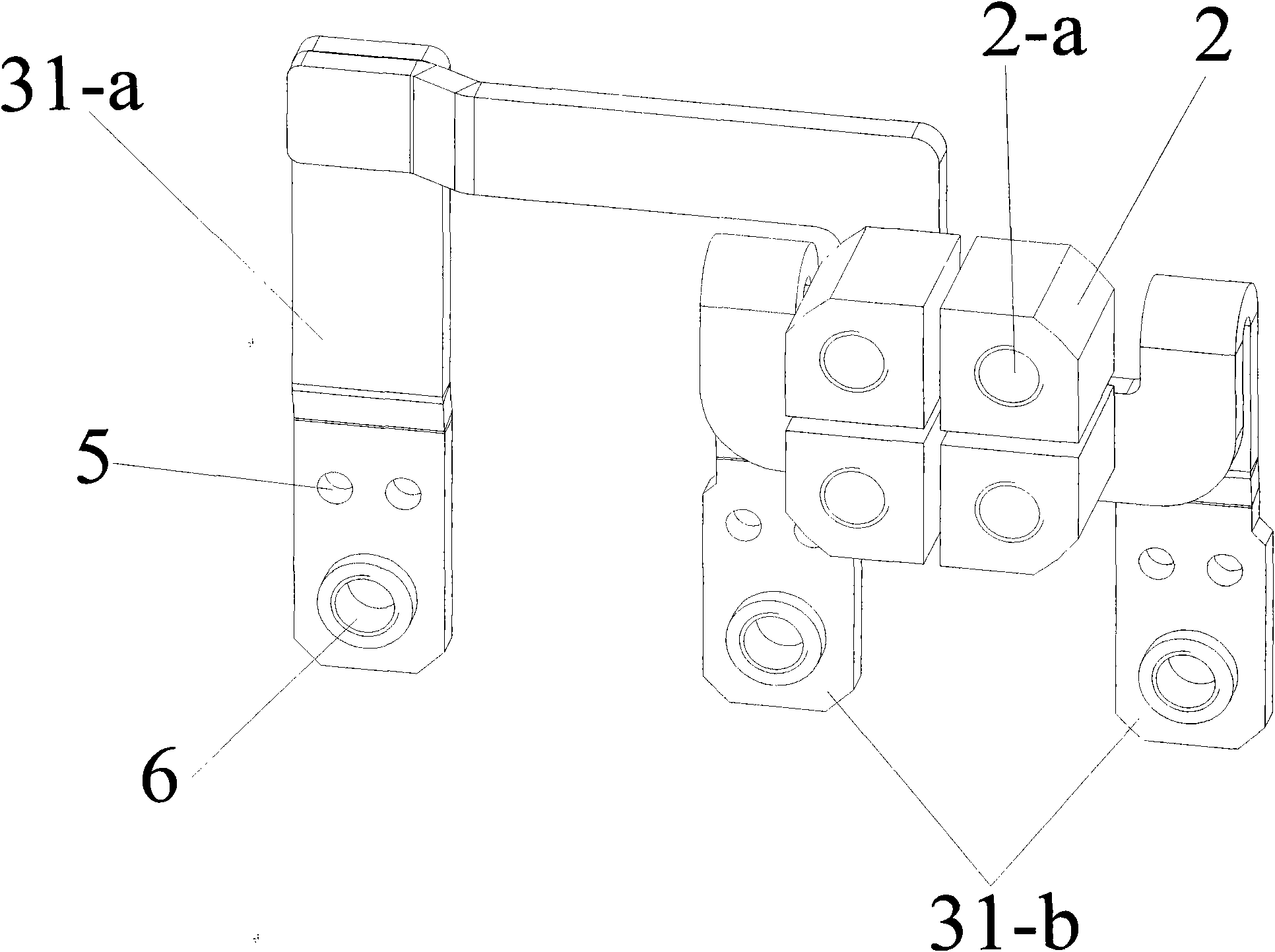

[0029] like Figure 1 to Figure 7 As shown, 1 is the body of the zero-sequence current transformer; 11 is the front separation area structure of the main body of the transformer, 11-a is the first area on the front, 11-b is the second area on the front, 11-c is the third area on the front, 11 -d is the fourth area on the front; 12 is the partition structure on the back of the main body of the transformer, 12-a is the first area on the back, 12-b is the second area on the back, 12-c is the third area on the back, and 12-d is the back The fourth area; 2 is a conductive copper rod, 2-a is a threaded hole; 31-a is the first back conductive copper row, 31-b is the second back conductive copper row, 32-a is the first front conductive copper row, 32-b is the second front conductive copper bar; 4 is the screw, 5 is the first hole on the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com