Integrated heating core for built-in porous heater and manufacturing method thereof

A heating core, built-in technology, used in heating elements, ohmic resistance heating parts, spaceflight aircraft propulsion system devices, etc., to achieve the effects of high heat exchange efficiency, good air permeability, and large space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

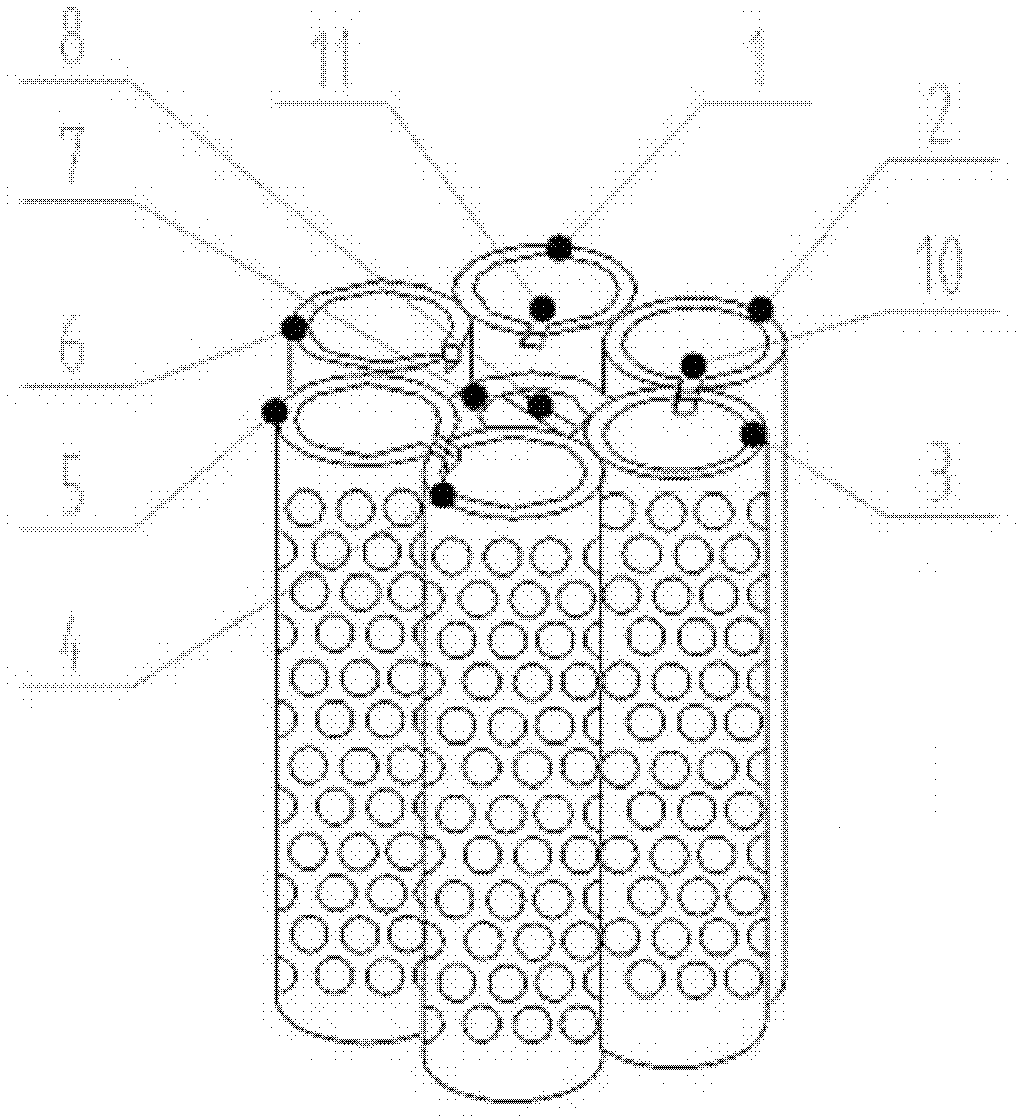

[0058] Integrated heating core skeleton for built-in porous heater such as figure 1 shown.

[0059] The built-in porous heater allows the overall space occupied by the integrated heating core to be Φ15mm×25mm; the length of the peripheral boron nitride tube is 25mm, the outer diameter is 5mm, and the wall thickness is 0.3mm; the length of the central boron nitride tube 7 is 20mm, The outer diameter is 5mm, and the wall thickness is 0.5mm; the size of the spacer 8 is 20mm×4mm×0.5mm.

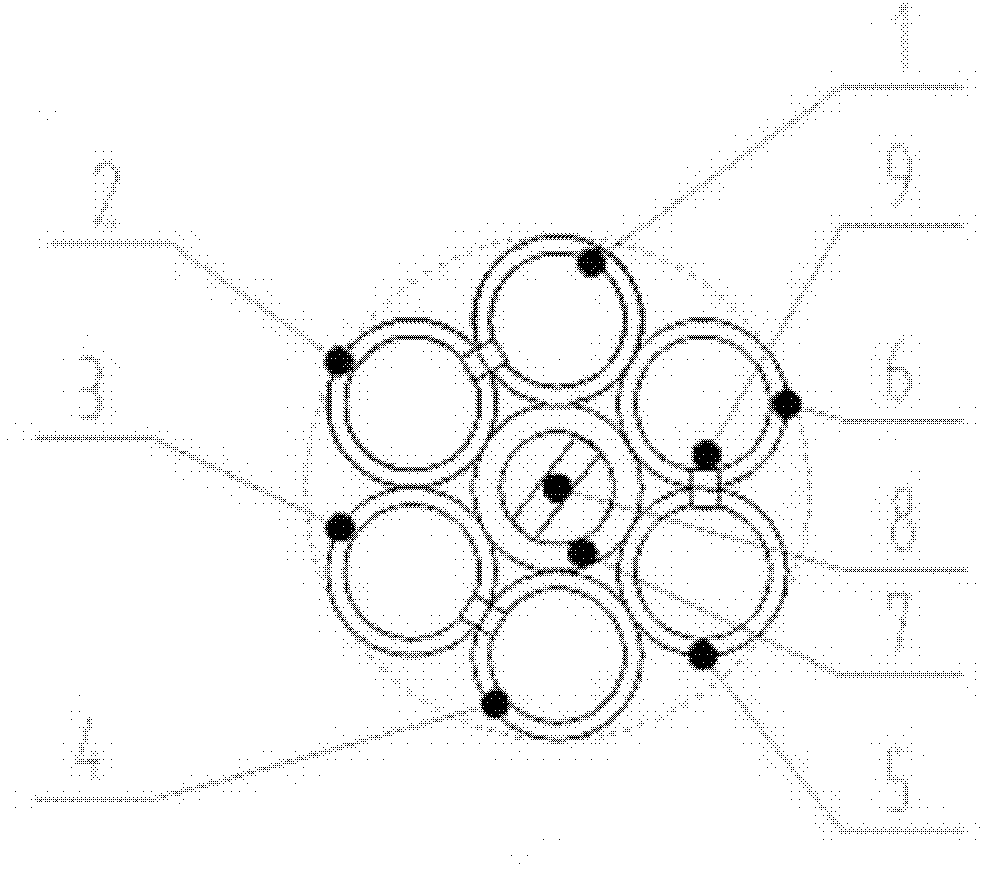

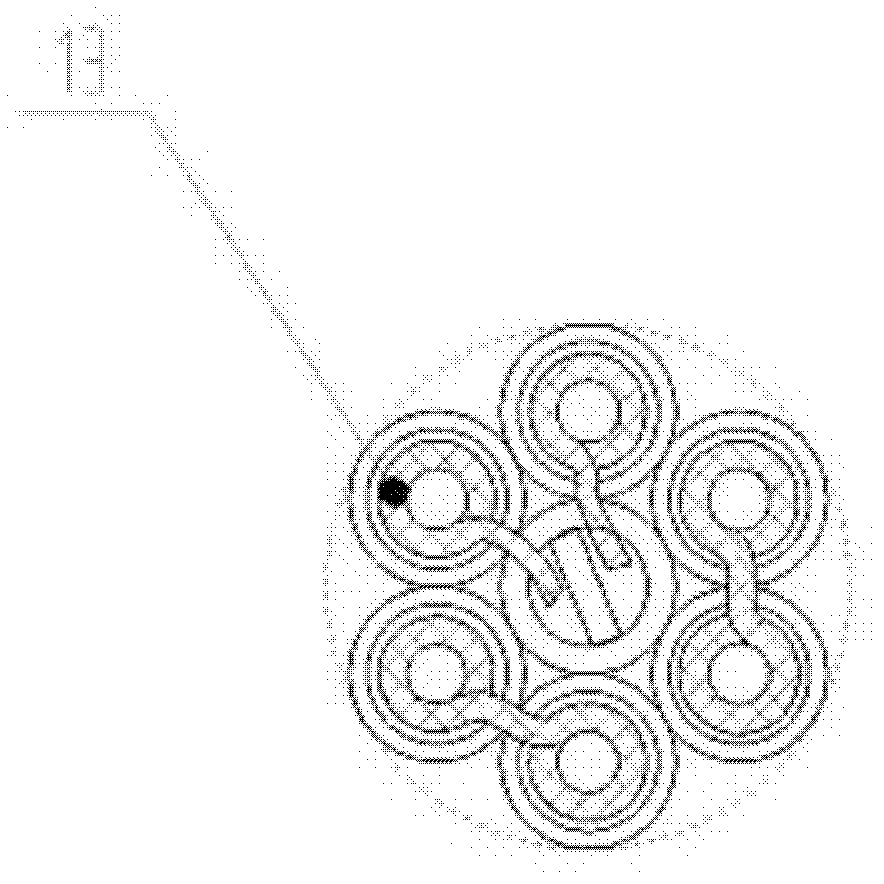

[0060] figure 1 It is the skeleton of the heating body, consisting of a peripheral boron nitride tube and a slightly shorter central boron nitride tube 7 with a boron nitride spacer 8, and the peripheral boron nitride tube is centered on the central boron nitride tube 7 of the same diameter Form a close-packed structure; at the same time, it indicates that the boron nitride tube on the rear end face of the heating element skeleton has two double-wall notches 10 on the rear end face, which are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com