Flame-retardant carbon crystal heating plate and preparation method thereof

A heating plate, carbon crystal technology, applied in ohmic resistance heating, electric heating devices, heating element materials, etc., can solve the problem of rapid temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0030] Preparation of graphite carbon paste: It is prepared by mixing conductive graphite powder, glass powder, zinc powder, terpineol, ethyl cellulose and sodium silicate according to the weight ratio of 100:30:20:15:5:2.

preparation example 2

[0032] Preparation of graphite carbon paste: It is prepared by mixing conductive graphite powder, glass powder, zinc powder, terpineol, ethyl cellulose and sodium silicate according to the weight ratio of 100:40:30:25:10:5.

Embodiment 1

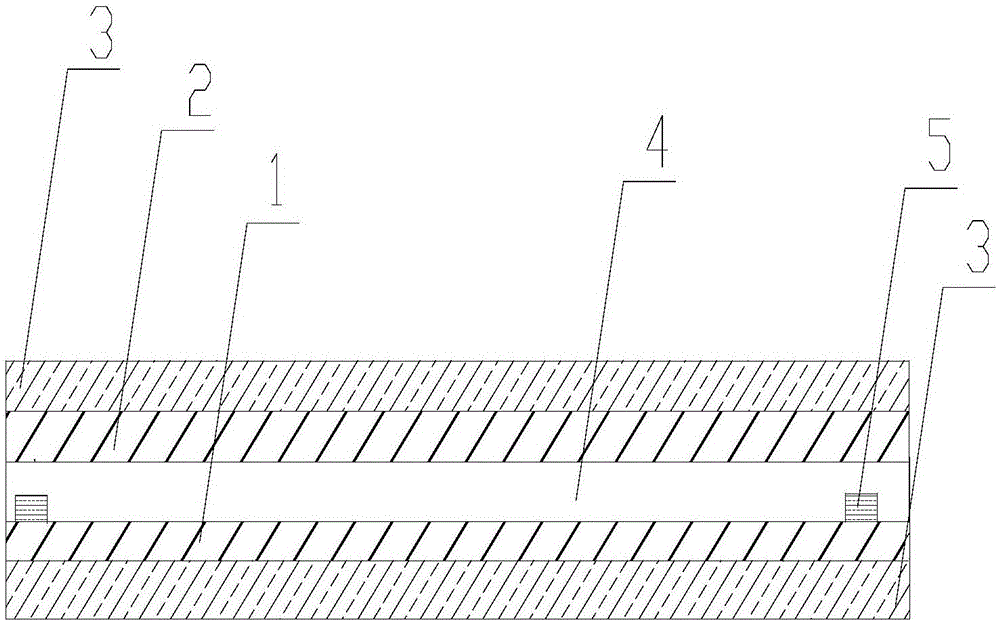

[0034] 1) First fix one end of the copper strip 5 on the front surface of the first resin layer 1 (thickness is 0.2 mm) and extend the other end to the outside of the first resin layer 1;

[0035] 2) Then, the graphite carbon slurry is coated on the front surface of the first resin layer 1 to form a graphite layer 4 (thickness is 0.2mm), and one end of the copper strip 5 is coated on the graphite carbon slurry coating Inside;

[0036] 3) hot pressing the second resin layer 2 (0.2 mm in thickness) at a pressure of 13 MPa and 170° C. for 4 hours, and hot pressing on the graphite layer 4 to obtain a sandwich panel;

[0037] 4) hot pressing the mica paper 3 (0.2 mm in thickness) on both sides of the sandwich panel, and naturally cooling to obtain the flame retardant carbon crystal heating panel A1;

[0038] Wherein, graphite carbon paste is made by preparation example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com