An integral 120-degree outlet electrical connector plug

A technology of connector plugs and outgoing wires, which is applied in the direction of connection, two-part connection device, and parts of the connection device. It can solve the problems of low assembly efficiency, low shielding efficiency, and high cost, and achieve high assembly efficiency and increase creepage. The effect of distance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

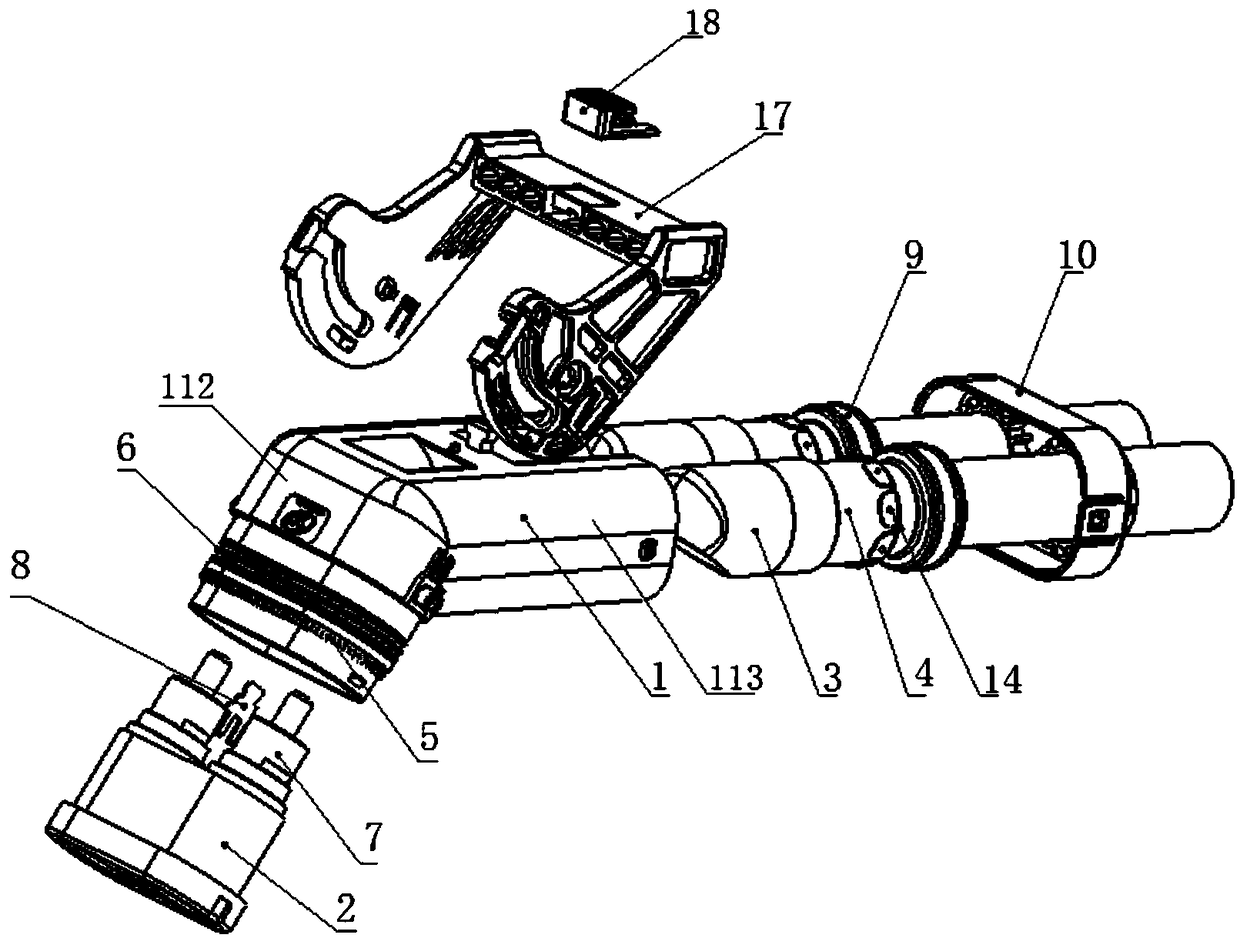

[0048] Such as Figure 1-10 As shown, an integral 120-degree outgoing electrical connector plug is characterized in that it includes a plug housing 1, a plug front mounting plate 2, a pin assembly 7, a signal shorting piece 8 and a plug tail cover 10;

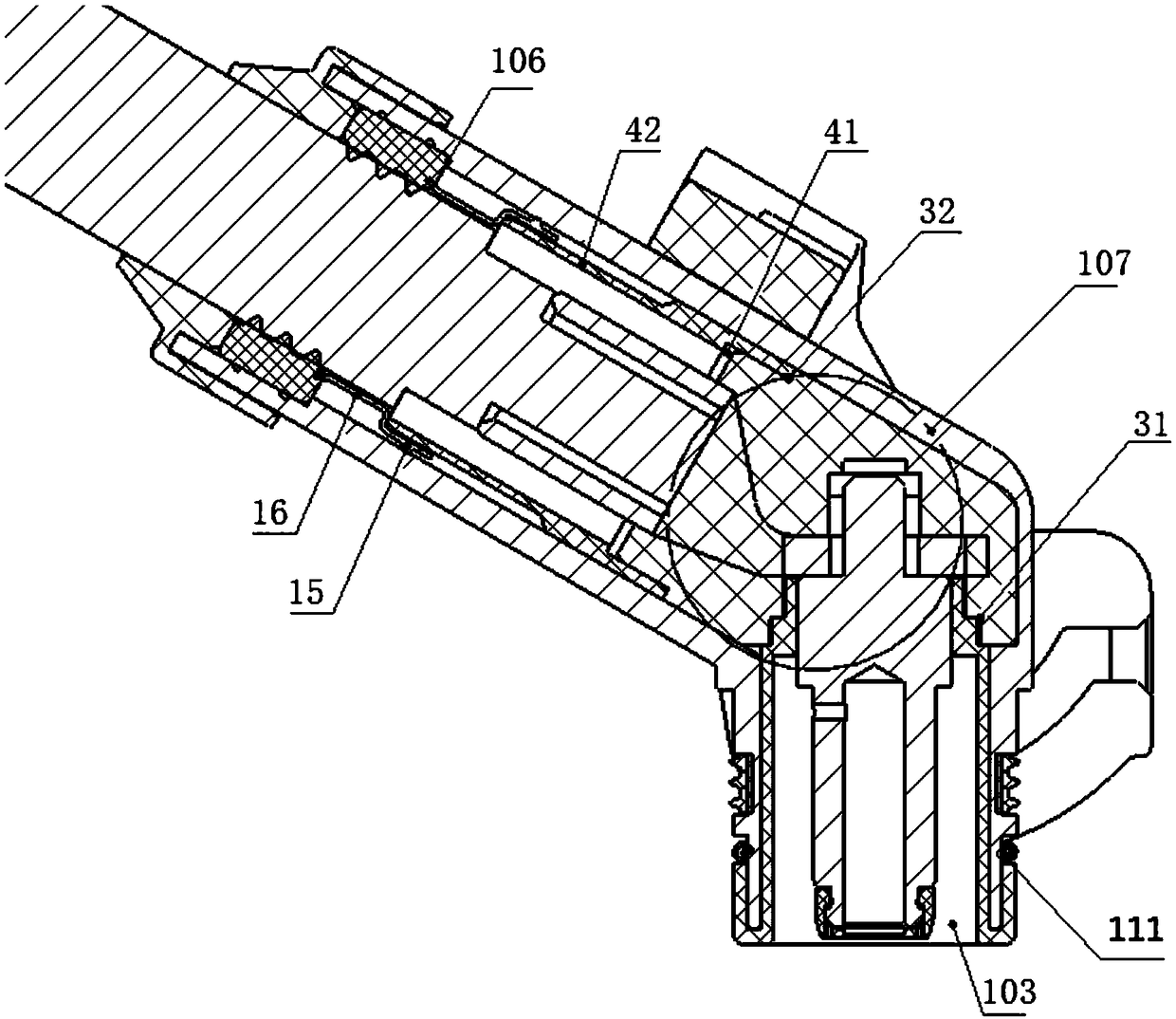

[0049] The plug housing 1 includes a plug housing front end 112 and a plug housing rear end 113 connected to the plug housing front end 112, and the angle between the plug housing front end 112 and the plug housing rear end 113 is 120 degrees, and the plug housing The front end 112 of the body is provided with a housing cavity 103 for the front mounting plate of the plug, the front mounting plate 2 of the plug is installed in the housing cavity 103 of the front mounting plate 2 of the plug, and the internal two sides of the front end of the front mounting plate 2 of the plug are provided with housing cavities for pin components 22. The pin assembly 7 is arranged in the housing chamber 22 of the pin assembly, and the center of t...

Embodiment 2

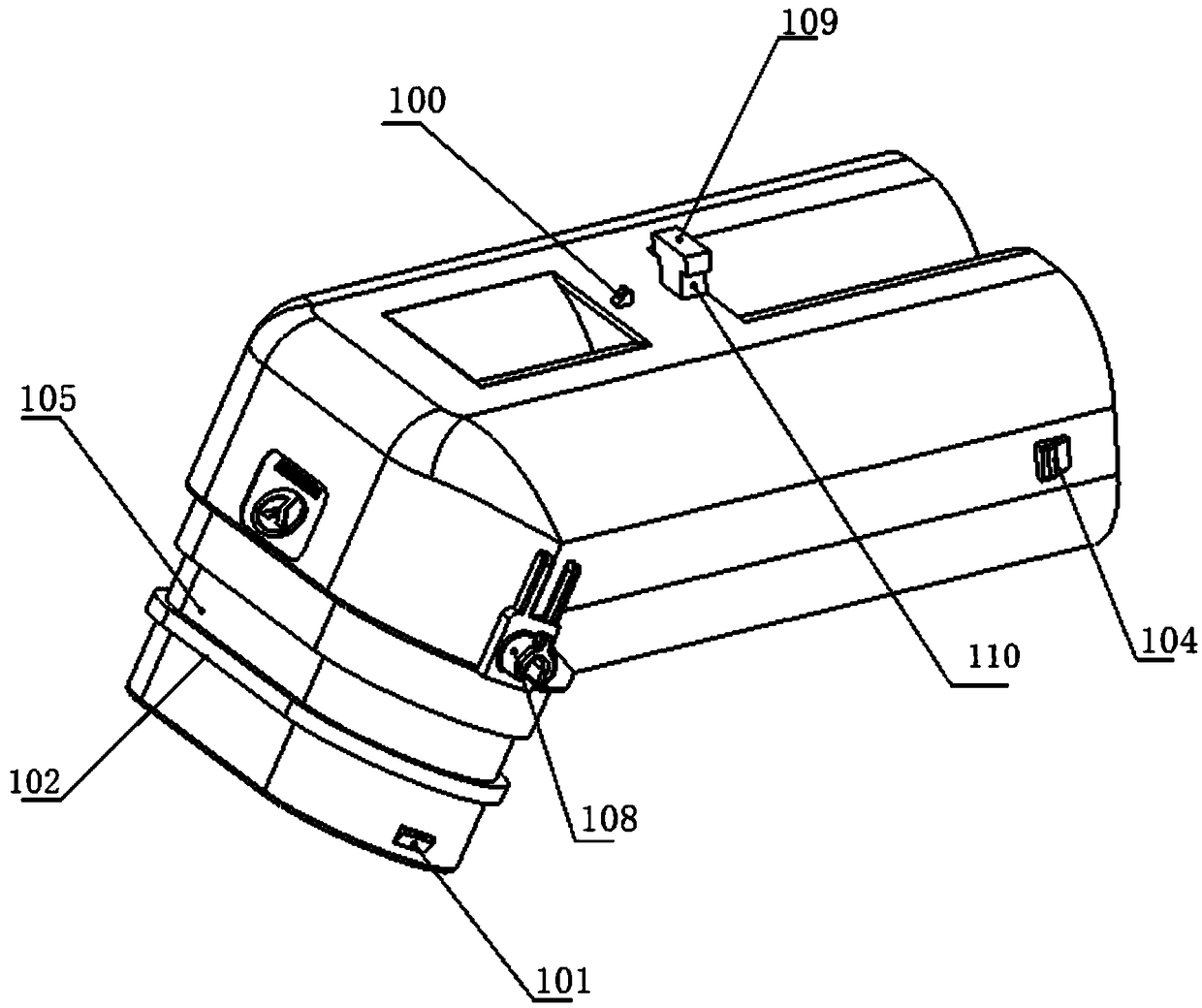

[0061] Such as Figure 8-9 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the plug shell of the present invention Both sides of the body front end 112 are respectively provided with a cylindrical rotating shaft 108, and the top of the plug housing rear end 113 is provided with a boss 109 and a wedge-shaped slider 100. The plug housing 1 is provided with a locking handle 17, and the locking Both sides of the handle 17 are respectively provided with shaft holes 171 matched with the cylindrical shaft 108, and the top of the locking handle 17 is provided with a draw-in groove matched with the boss 109, and the lock handle 17 is connected with the boss through the draw-in groove. The fit of the platform 109 and the fit of the shaft hole 171 and the cylindrical shaft 108 are provided on the plug housing 1 . The shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com