Angled high voltage shielded plug

A shielded plug, high-voltage technology, applied in the direction of coupling devices, electrical components, connections, etc., can solve problems such as the inability to meet the use requirements of new energy vehicles on the curved shielded plugs, the poor shielding effectiveness of the shielding treatment method, and the inability to meet the use requirements. , to achieve the effect of reducing quality and production cost, reliable fixing method and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

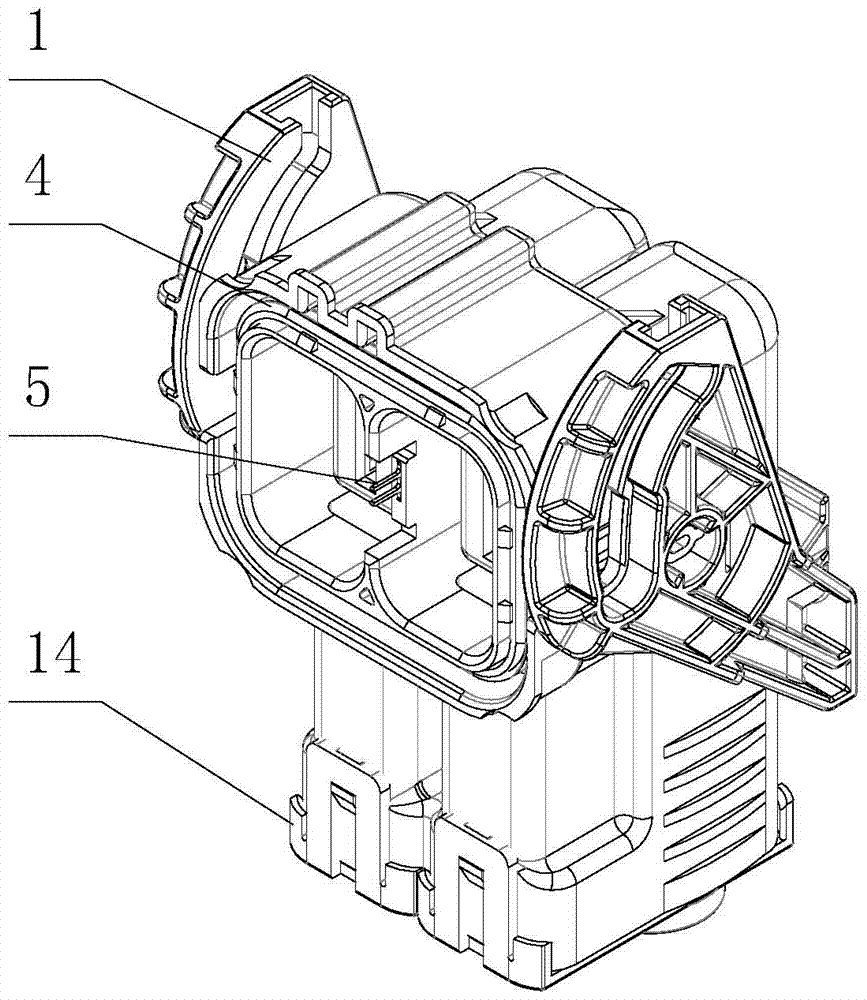

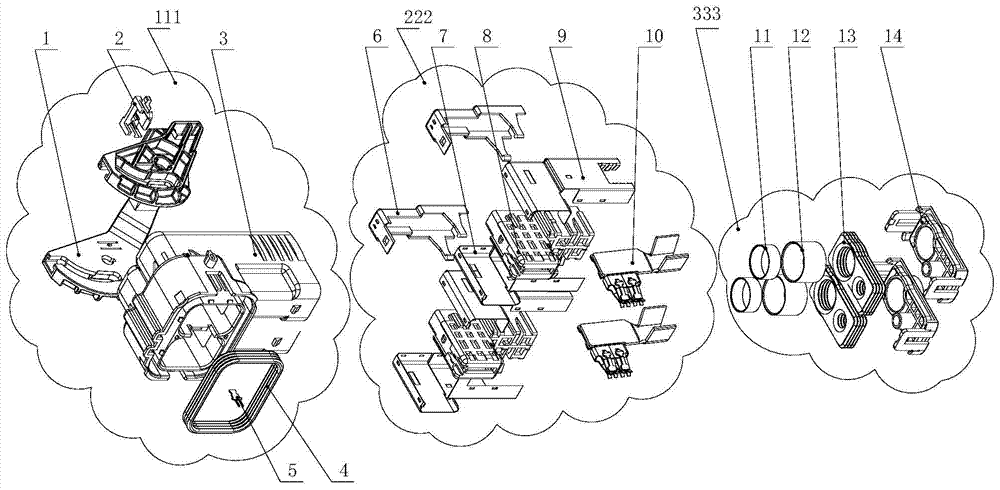

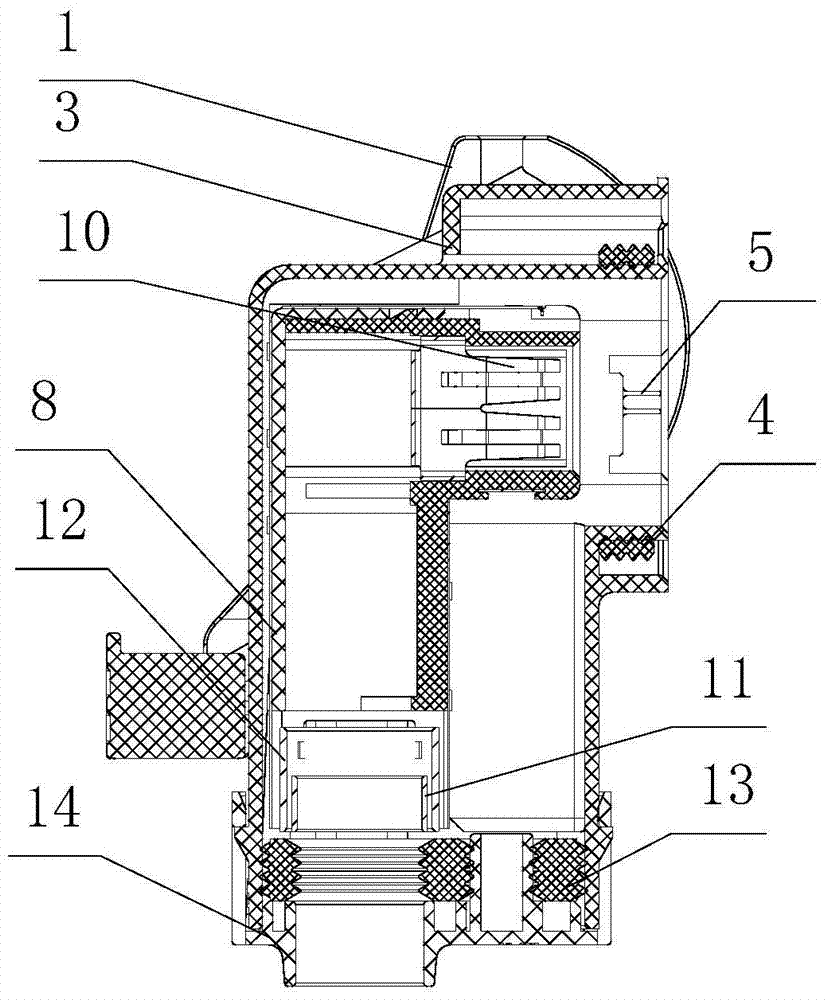

[0036] Such as Figure 1-3 As shown, a curved high-voltage shielded plug is composed of a shell assembly 111 , a contact piece and a mounting plate assembly 222 , and a tail attachment 333 .

[0037] The shell group 111 is composed of a locking handle 1, a lock block 2, a plug shell 3, a sealing ring 4, and a signal pin 5.

[0038] The contact piece and mounting plate assembly 222 is composed of a rear cover 6 , a left shield 7 , a front mounting plate 8 , a right shield 9 and a contact 10 .

[0039] Tail attachment 333 is made up of shielding pad cover 11 , shielding pressure sleeve 12 , sealing wire body 13 , and tail cap 14 .

[0040] Such as Figure 4 and Figure 5 As shown, the two sides of the plug shell 3 are symmetrically provided with two elliptical shafts 3-1, and a fool-proof keyway 3-2 is provided at the plug joint, and a locking buckle 3-3 is provided on the back of the plug shell 3. The tail is provided with a tail cap fixing buckle 3-4, and the plug housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com