Organic silicon resin encapsulant of large power LED and preparing method thereof

A resin encapsulation, silicone technology, used in electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

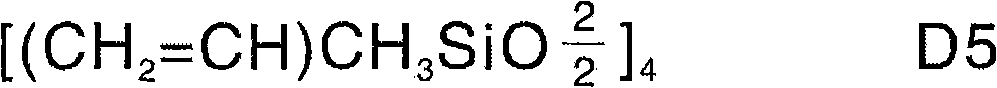

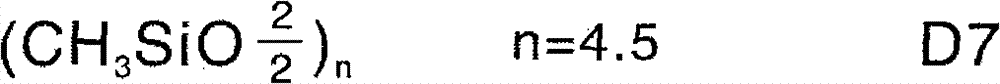

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: Preparation of the one-component silicone resin encapsulant of the present invention.

[0082] Synthesis and purification of component A

[0083] 1. Raw materials

[0084] ①Phenyltrichlorosilane, methylvinyldichlorosilane, and trimethylchlorosilane must be rectified, and the chromatographic purity of the middle part (head and tail parts) should be above 99.1%. Sealed for later use, steamed and used now.

[0085] ② Use the solvent toluene after distillation, and take the middle part (remove the head and tail part).

[0086] ③ Pure water is used for hydrolysis and washing.

[0087] 2. Synthesis reaction and refining

[0088] In the flask, 600 g of toluene and 350 g of pure water were added, stirred and mixed, and the mixture (169.2 g of phenyltrichloroalane, 28.2 g of methylvinyldichlorosilane) was added dropwise over about 40 minutes. After dropping, stir at 65°-70°C for 1 hour to carry out hydrolysis polycondensation reaction. Then the acidic aqueous...

Embodiment 2

[0122] Embodiments 2 and 3 The basic raw material polymer and diluent used in the two-component silicone resin encapsulation compound of the present invention and the solidification examples 2 and 3 are all of the same product, and the dosage is the same, only the crosslinking agent component Not the same, now the preparation methods of this example 2 and example 3 will be explained together, and the preparation will be explained separately.

[0123] Synthesis and purification of component A

[0124] 1. Raw materials:

[0125] ①Dimethyldichlorosilane, methylvinyldichlorosilane, and phenyltrichlorosilane are all purchased from outsiders. They need to be rectified again, and the middle part is taken to ensure a purity of about 99.5%. Sealed and stored for future use, no metal ions remain .

[0126] ② The solvent toluene isopropanol must be re-distilled before use.

[0127] ③ Pure water is used for hydrolysis and washing.

[0128] 2. Synthesis reaction and refining

[0129] ...

Embodiment 3

[0189] Example 3: Preparation of two-component silicone resin encapsulant

[0190] Accurately add the refined and qualified products of the following components

[0191] Component A base resin is taken with the consistent structure 100g in the above-mentioned embodiment example two

[0192] Component B-1 diluent takes the same structure as 11.1g in the above-mentioned embodiment example two

[0193] Component B-2 diluent takes the same structure as 22.2g in the above-mentioned embodiment example two

[0194] Component C, 85g of methyl phenyl siloxane resin oligomer containing H groups, its average composition formula is 0.5 segments of D31, 0.5 segments of D18, H content of 0.53% by mass, SiH / SiCH=CH 2 The matching of this example is 1:1

[0195]

[0196] Component D, platinum catalyst (platinum content is 5%) platinum-1.3-divinyltetramethyldisiloxane mixture (self-made) 0.22g, the amount of platinum added is 11ppm of the total amount of silofane added.

[0197] Compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com