Method for manufacturing LED streetlight lens and lens thereof

A technology of LED street lamps and manufacturing methods, which is applied in the field of light transmission, can solve the problems of poor light output effect, inability to better control the illuminated area and shape, etc., and achieve good light output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

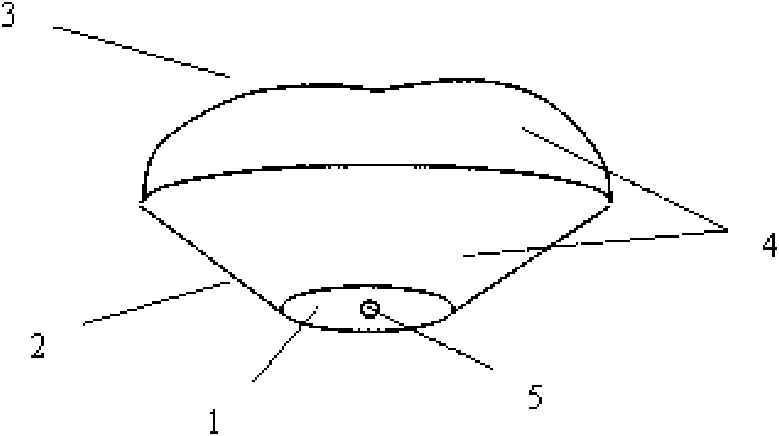

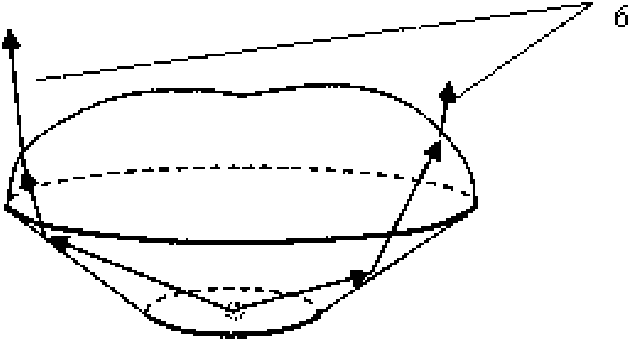

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

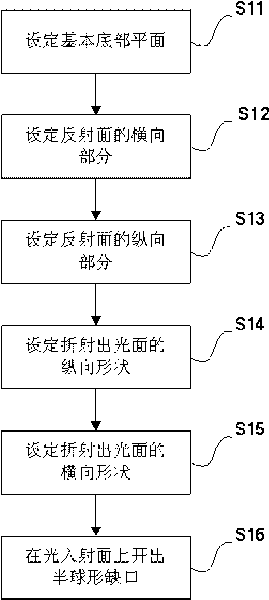

[0029] Such as figure 1 Shown, in a kind of LED street lamp lens manufacturing method of the present invention and lens embodiment thereof, its manufacturing method comprises the following steps:

[0030] Step S11 sets the basic bottom plane: In this embodiment, the LED street lamp lens consists of the light incident surface on which the LED is placed, the refraction light exit surface opposite to the above light incident surface, and the sides connected to the above light incident surface and the refraction light exit surface respectively. The light-emitting surface is closed. In this step, the basic bottom plane of the lens is set. In this embodiment, the basic bottom plane refers to the plane connecting the refracting light surface and the emitting surface in the lens. This plane is not an actual plane in the lens. It is not a physical plane, but a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com