Preparation method of white chip for LED (Light Emitting Diode)

A LED chip and white light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low uniformity, yellow circles, light spots, etc., achieve good consistency of light emission, reduce raw material costs, and improve product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

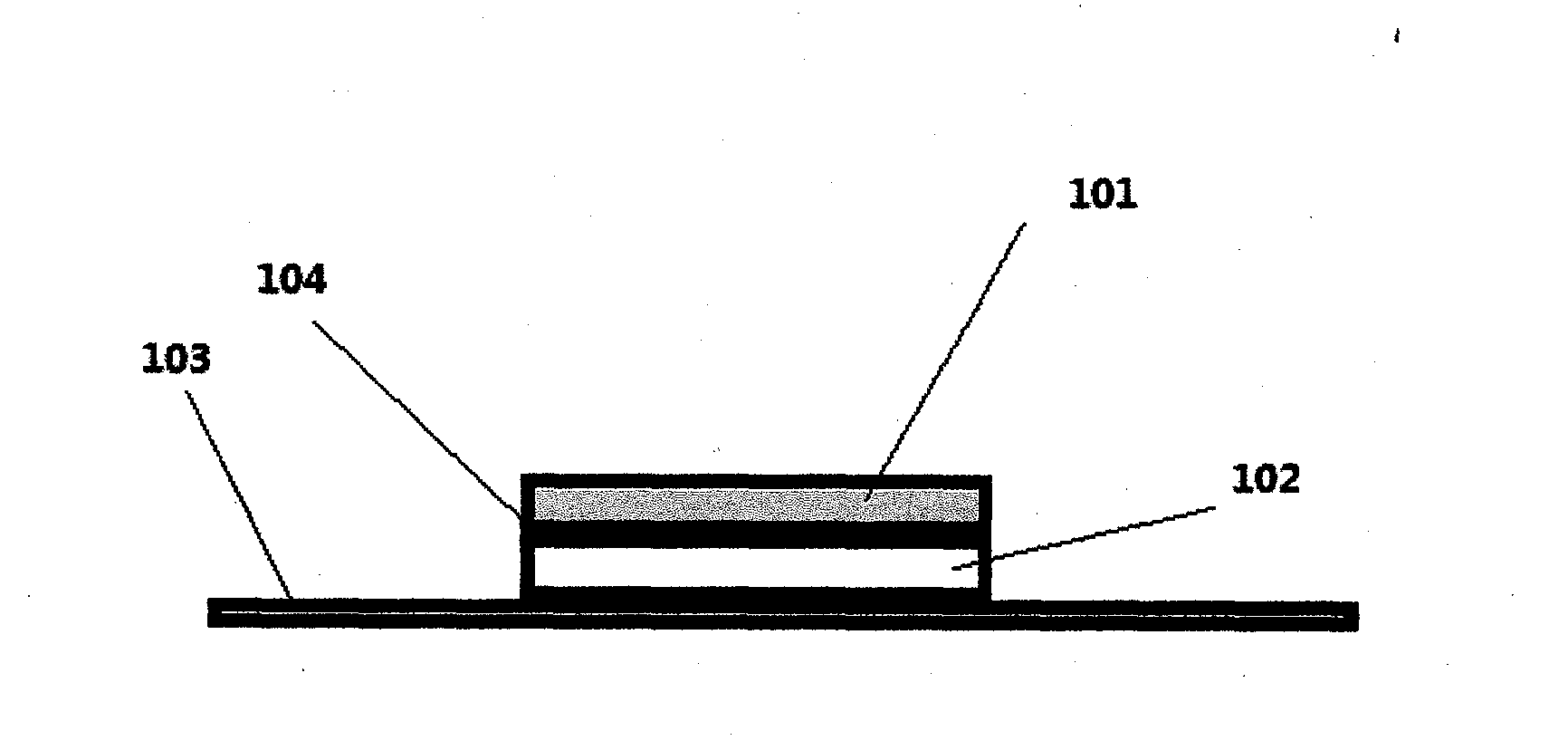

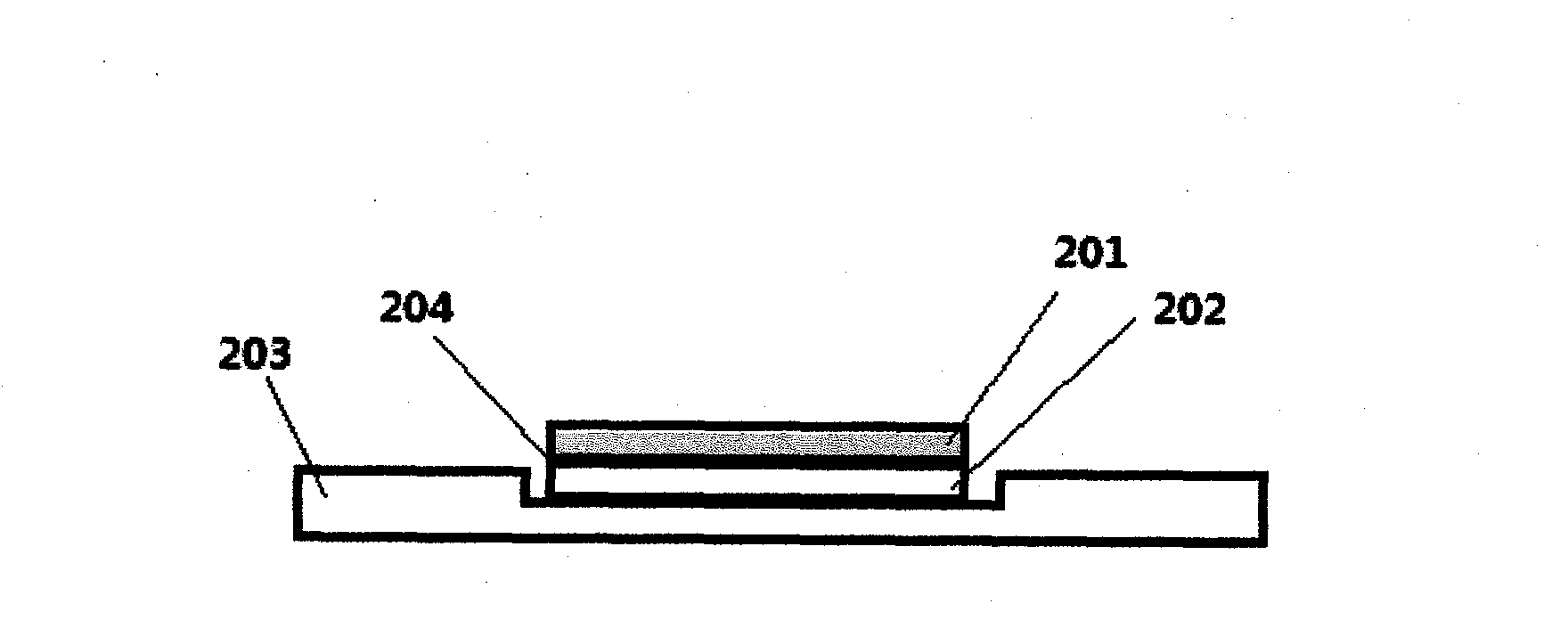

[0025] The preparation method of a white light chip for an LED comprises raw materials of a prefabricated film (101, 201) of fluorescent powder for a white light LED, an adhesive (104, 204), and an LED chip (102, 202). It is characterized in that the chip (102) for LED is pasted on the blue film (103), and a prefabricated film (101) of fluorescent powder for white light LED is pasted on the LED chip (102) through an adhesive (104). Above, at an ambient temperature of 80-200° C. for 1 to 6 hours, the adhesive is cured to obtain a white light chip for LED. Or paste the chip (202) for LED on the blue film (203), and paste a prefabricated film (201) of phosphor powder for white light LED on the LED chip (202) through a naturally curable adhesive (204). and stand still for 1 to 10 hours to allow the adhesive (204) to cure naturally to obtain a white light chip for LED.

[0026] The shape and size of the phosphor prefabricated film (101, 201) for a white light LED completely coinci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com