Coating technique of LED fluorescent powder

A coating process and phosphor technology, applied in the directions of coating, electrolytic coating, electrophoretic plating, etc., can solve the problem of direct coating of phosphors, and achieve the effect of good consistency, strong controllability and uniform light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

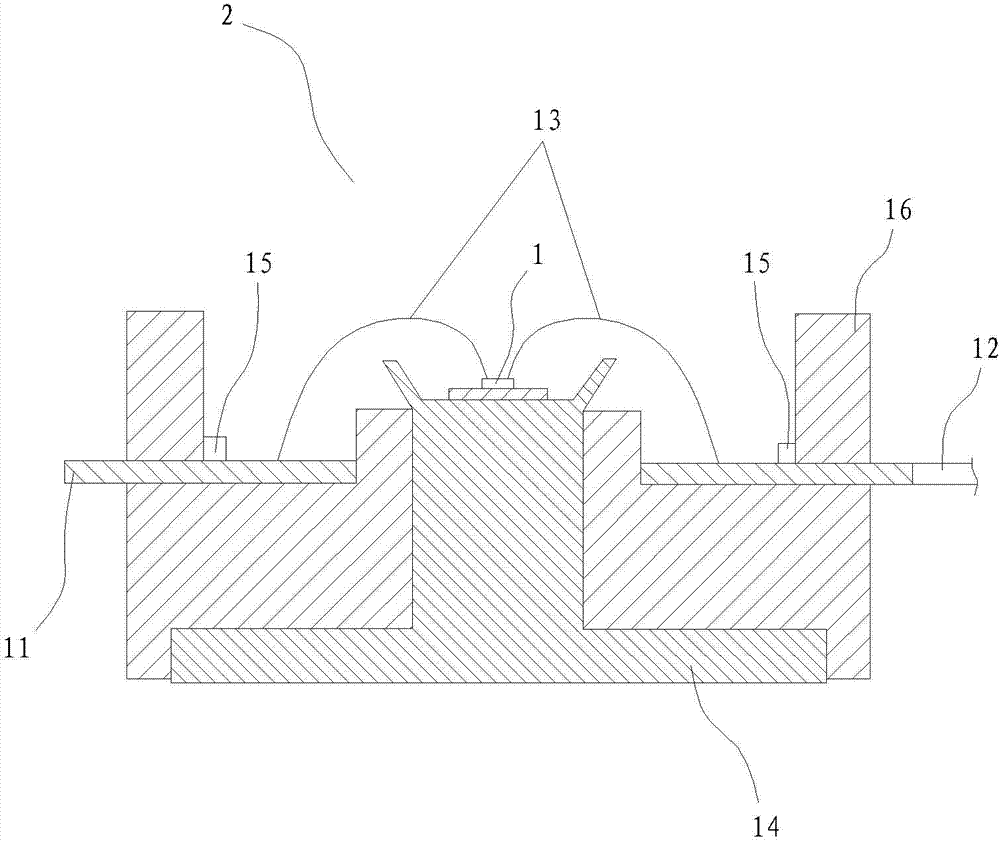

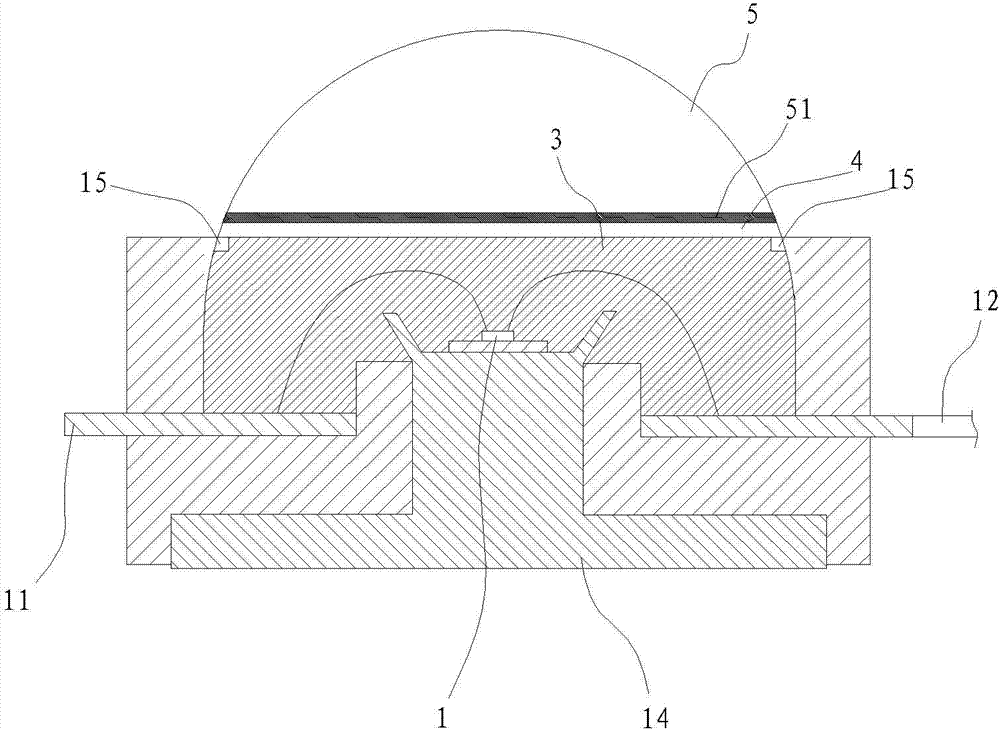

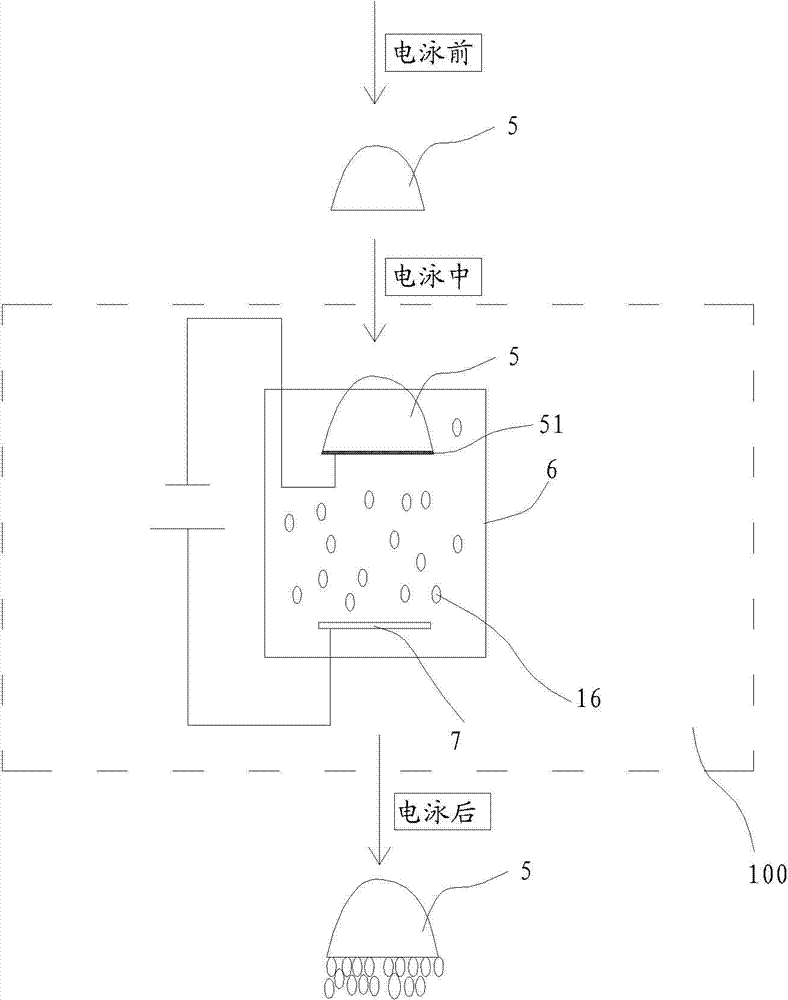

[0039] The high-power LED bracket is now taken as a specific example to illustrate the LED phosphor coating process of the present invention. Such as figure 1 with figure 2 As shown, the LED packaging structure includes an LED chip 1 , a bracket 2 , a silica gel layer 3 , a phosphor layer 4 , and an optical lens 5 . The non-light-emitting surface of the optical lens 5 is provided with an ITO (Indium Tin Oxides, nanometer indium tin metal oxide) conductive layer 51 , and the outer surface of the optical lens 5 is in the shape of a free-form surface and has no conductive function.

[0040] The bracket 2 is provided with a cup and bowl for placing the LED chip 1, a positive conductive pin 11 and a negative conductive pin 12 leading out the positive and negative poles of the LED chip 1 through a wire 13, and a cover covering the positive conductive pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com