Foam metal-carbon nanotube composite material, and preparation method and application thereof

A foam metal, carbon nanotube technology, applied in the direction of carbon nanotubes, metal material coating process, nano carbon, etc., can solve the problem of uneven distribution of carbon nanotubes, and achieve controllable and uniform diameter and good dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

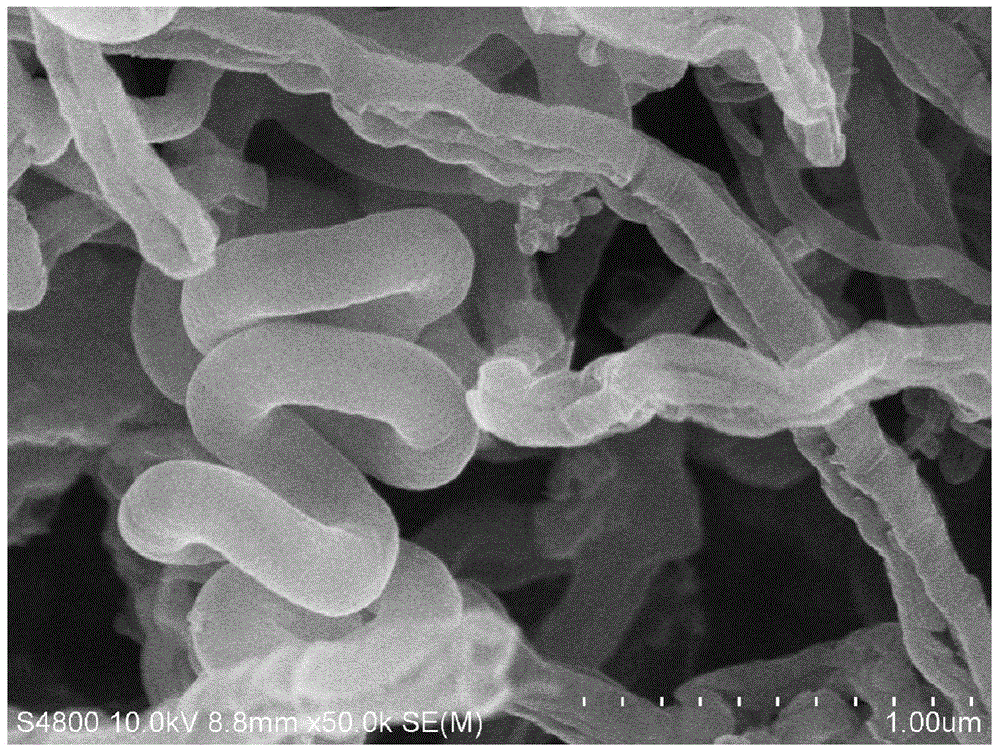

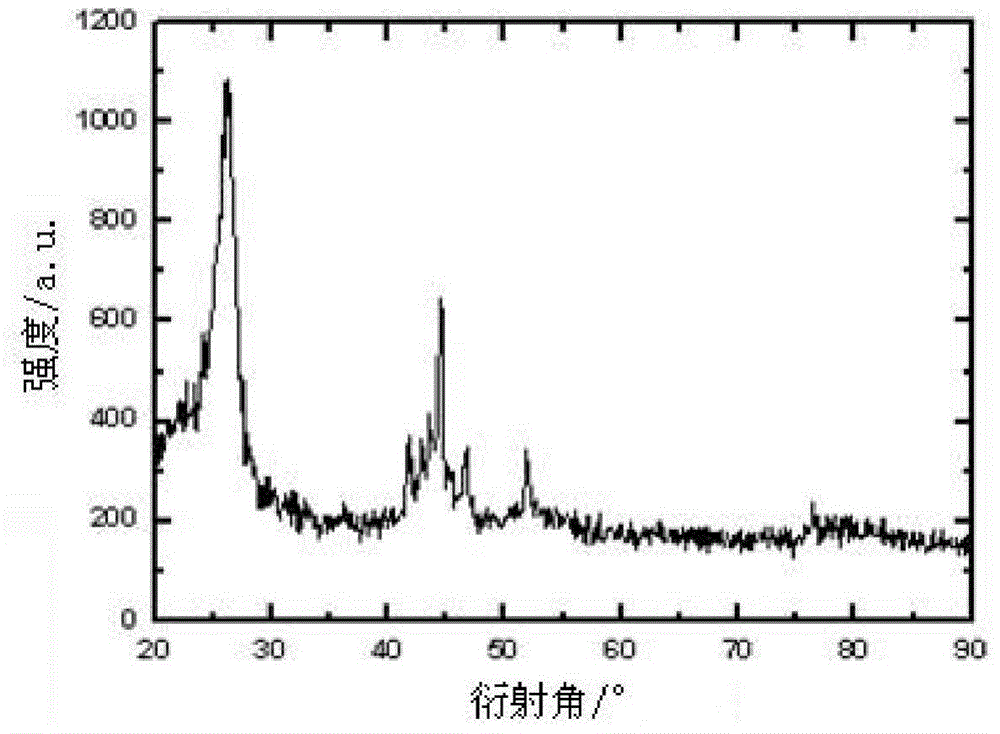

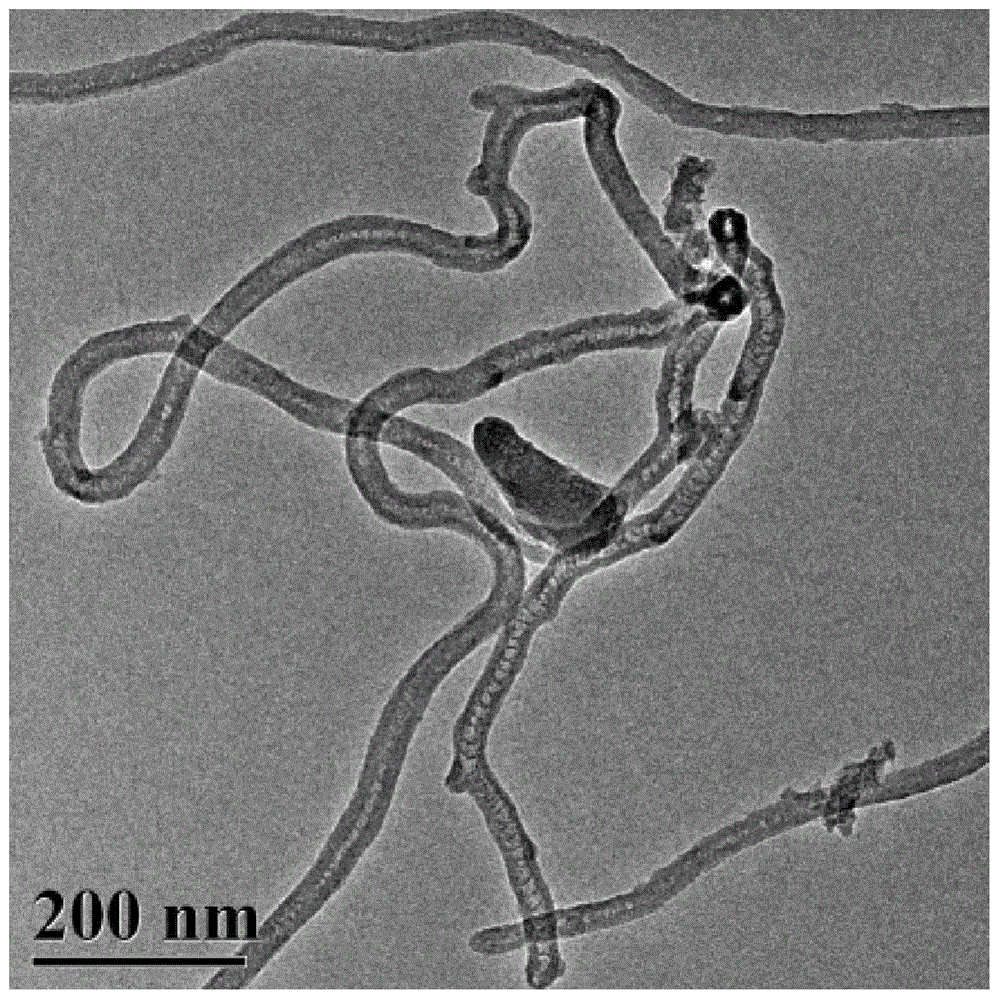

Embodiment 1

[0034] Divide the area into 5×5cm 2 The polyurethane sponge (weight is 110mg) carries out pretreatment. That is, after chemical degreasing (NaOH: 15g / L, NaOH: 3 PO 4 : 15g / L, Na 2 CO 3 :10g / L, 35℃, 4min), deionized water washing, potassium permanganate roughening (KMnO 4 :6g / L, H 2 SO 4 : 12mL / L, room temperature, 3min), deionized water washing, oxalic acid reduction (C 2 h 2 o 4 : 15g / L, room temperature, 2min), deionized water washing, sensitization (SnCl 2 :25g / L, HCl:40mL / L, room temperature, 3min) and colloidal palladium activation (PdCl 2 : 0.5g / L, HCl: 40mL / L, room temperature, 4min). After pretreatment, electroless nickel plating (NiSO 4 :30g / L, NaH 2 PO 2 : 10g / L, Na 3 Cyt: 35g / L, Na 3 PO 4 : 50g / L, 45 DEG C, 1.5h), make polyurethane sponge substrate surface coating nickel foam to obtain the foam nickel catalyst of polyurethane sponge substrate, weigh after drying and obtain gross mass be 185mg, wherein foam nickel 75mg, account for polyurethane spong...

Embodiment 2

[0037] The pretreatment steps of the polyurethane sponge of the present embodiment are exactly the same as that of Example 1. After pretreatment, electroless copper plating (CuSO 4 : 10g / L, Na 3 Cyt: 24g / L, NiSO 4 :3g / L, H 3 BO 3 : 30g / L, NaOH: 10g / L, NaH 2 PO 2 : 30g / L, 60 ℃, 1h), make polyurethane sponge substrate surface coating foam copper catalyst obtain the foam copper catalyst of polyurethane sponge substrate, weigh after drying and obtain gross mass be 160mg, wherein foam copper 50mg, account for polyurethane sponge substrate quality 45%.

[0038] Put the foamed copper catalyst of the polyurethane sponge substrate above in a tube furnace, pass nitrogen protection, then raise the temperature of the tube furnace from room temperature to 550 ° C at a heating rate of 15 ° C / min, feed hydrogen and keep it for 1 hour ; The temperature was raised to 800°C at a heating rate of 15°C / min, and 10% acetylene gas mixture (nitrogen: acetylene=1:9, volume ratio) was introduc...

Embodiment 3

[0040] The pretreatment steps of the polyurethane sponge of the present embodiment are exactly the same as that of Example 1. After pretreatment, the polyurethane sponge was electrolessly plated with cobalt (CoSO 4 :28g / L, NaH 2 PO 2 : 25g / L, Na 3 Cyt: 60g / L, H 3 BO 3 : 30g / L, 80 DEG C, 0.5h), the cobalt foam catalyst that makes polyurethane sponge substrate surface coating foam cobalt obtains polyurethane sponge substrate.

[0041] Put the foamed cobalt catalyst of the polyurethane sponge substrate above in a tube furnace, protect it with nitrogen, then raise the temperature of the tube furnace from room temperature to 500 °C at a rate of 12 °C / min, feed hydrogen and keep it for 1 hour ; The temperature was raised to 600°C at a heating rate of 10°C / min, and 10% acetylene gas mixture (nitrogen: acetylene=1:9, volume ratio) was introduced at a rate of 50mL / min as a carbon source, Carbon nanofibers were grown by chemical vapor deposition on the surface of the cobalt cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com