Gamma-Fe2O3/SiO2 nano-grade composite material preparation method, and nano-grade composite material particles

A nano-composite material and nano-particle technology is applied in the field of metal oxide composite materials to achieve the effect of strong magnetic reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] γ-Fe 2 o 3 / SiO 2 The preparation method of the nanocomposite specifically includes the following three steps.

[0038] The first step is to synthesize γ-Fe by high temperature liquid phase method 2 o 3 Nanoparticles;

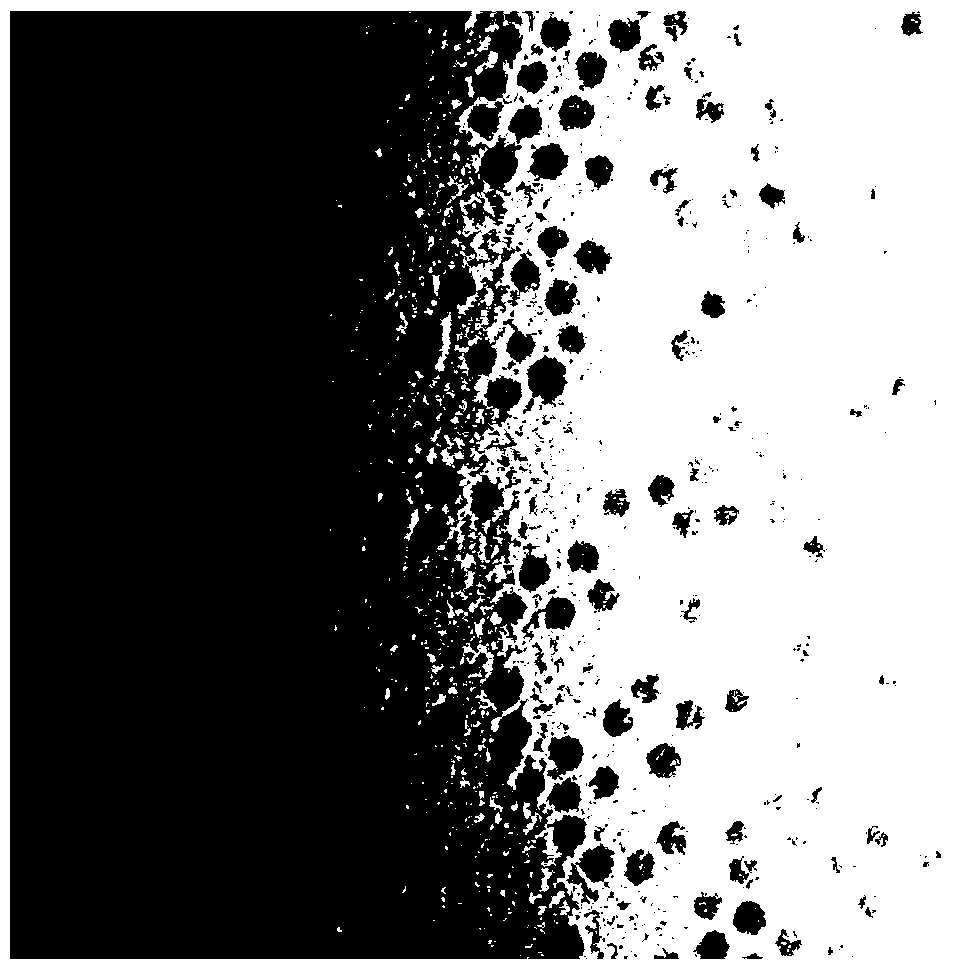

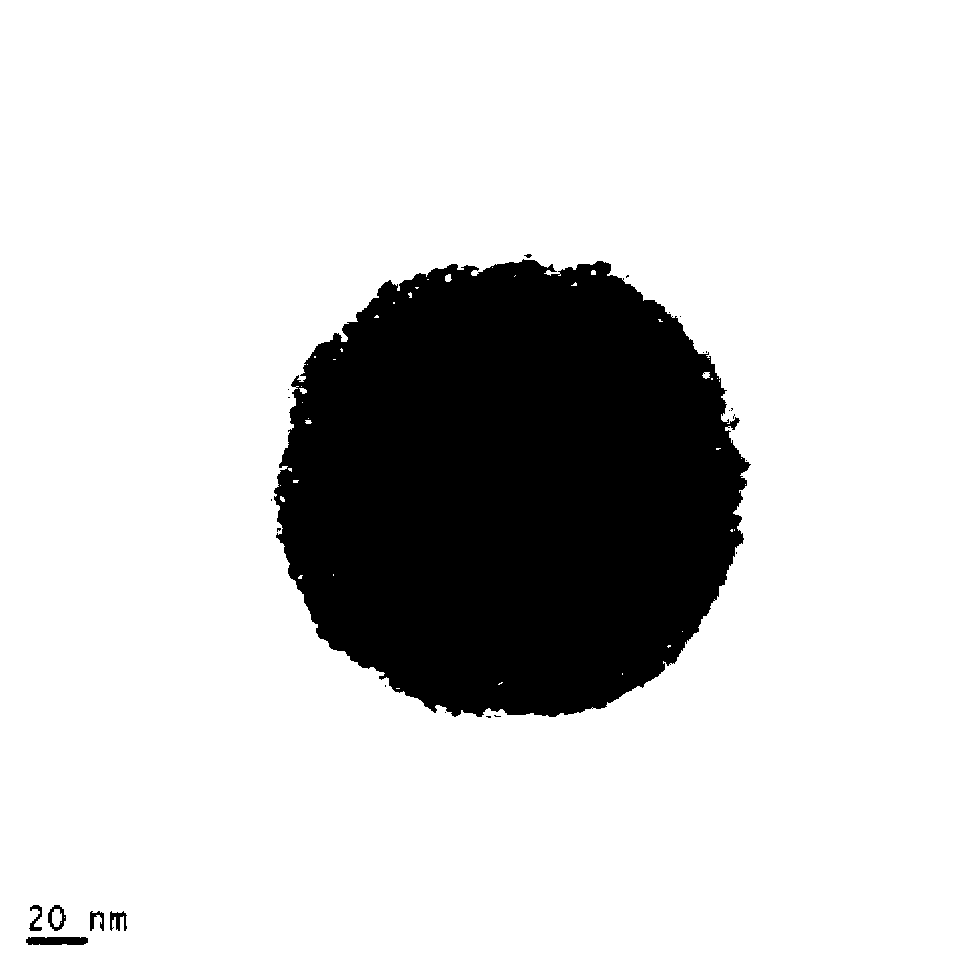

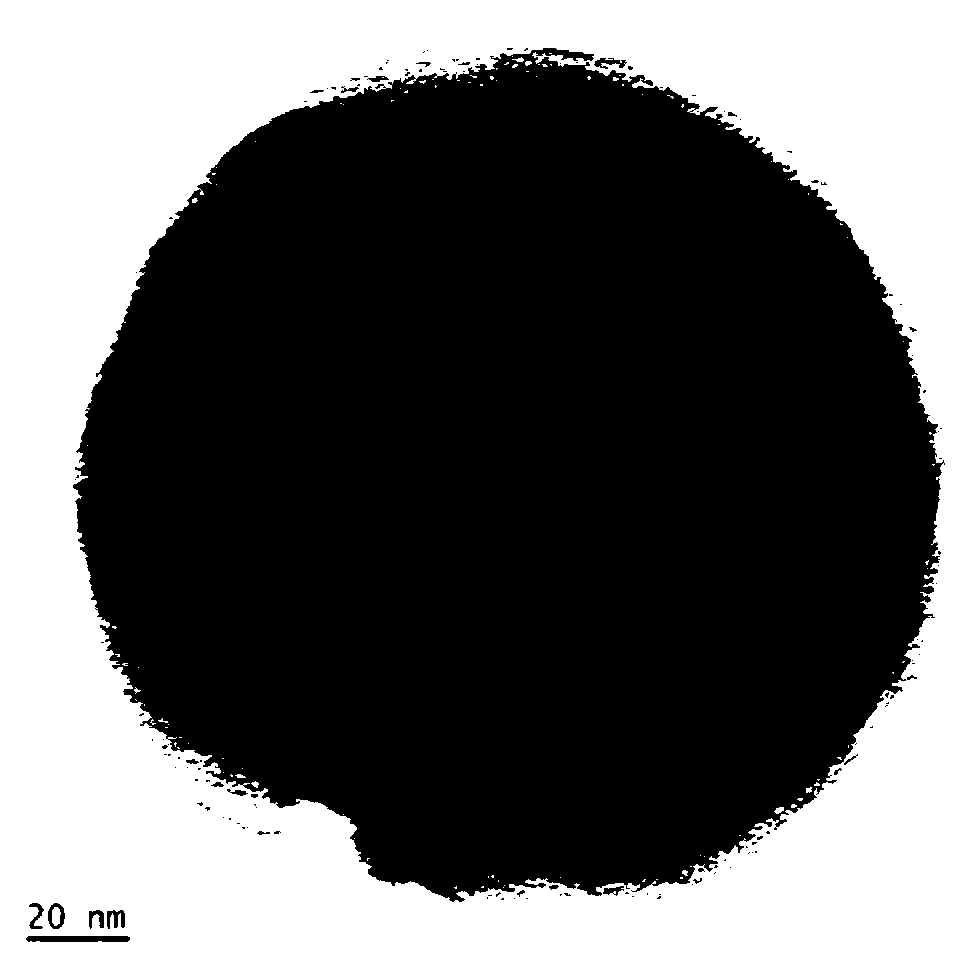

[0039] A mixture of 1.44mL octadecenoic acid (pure solution) and 10mL octyl ether (pure solution) was heated at 100°C for 30min under argon protection; then 0.2mL Fe(CO) 5 Octyl ether solution (wherein Fe(CO) 5 Concentration of 0.34g / ml) was quickly added to the above mixture, reacted at 295°C for 60min; finally cooled to 200°C, passed air into the system for 2h, cooled to room temperature, washed three times with ethanol and cyclohexane respectively, and then The synthesized γ-Fe 2 o 3 Nanoparticles were dispersed into 5mL of cyclohexane, ready to use. γ-Fe taken by transmission electron microscope 2 o 3 Photos of nanoparticles such as figure 1 shown.

[0040] In the second step, the γ-Fe 2 o 3 Nanoparticles are transferred from the oil p...

Embodiment 2

[0046] Heat the mixture of 1mL octadecenoic acid (pure solution) and 10mL octyl ether (pure solution) at 100°C for 30min under the protection of argon; then add 0.5mL Fe(CO) 5 Octyl ether solution (wherein Fe(CO) 5 Concentration of 0.34g / ml) was quickly added to the above mixture, reacted at 290°C for 70min; finally cooled to 200°C, passed air into the system for 2h, cooled to room temperature, washed three times with ethanol and cyclohexane respectively, and then The synthesized γ-Fe 2 o 3 Nanoparticles were dispersed into 5mL of cyclohexane, ready to use.

[0047] 78 mg sodium lauryl sulfate, 10 mL deionized water, 280 μL dispersed with γ-Fe 2 o 3 Nanoparticles of cyclohexane, mixed with 620 μL cyclohexane, ultrasonically assisted for 8 minutes, then kept at 70°C for 4 hours, and finally cleaned by centrifugation. The cleaning solvent was deionized water. After three times of cleaning, γ-Fe 2 o 3 clusters and disperse them in 1 mL of deionized water for later use.

[...

Embodiment 3

[0050] Heat the mixture of 1mL octadecenoic acid (pure solution) and 12mL octyl ether (pure solution) at 100°C for 30min under the protection of argon; then add 0.1mL Fe(CO) 5 Octyl ether solution (wherein Fe(CO) 5 Concentration of 0.34g / ml) was quickly added to the above mixture, reacted at 295°C for 60min; finally cooled to 200°C, passed air into the system for 2h, cooled to room temperature, washed three times with ethanol and cyclohexane respectively, and then The synthesized γ-Fe 2 o 3 Nanoparticles were dispersed into 5mL of cyclohexane, ready to use.

[0051] 50 mg sodium lauryl sulfate, 10 mL deionized water, 350 μL dispersed with γ-Fe 2 o 3 Nanoparticles of cyclohexane, mixed with 600 μL cyclohexane, ultrasonically assisted for 8 minutes, then kept at 70°C for 4 hours, and finally cleaned by centrifugation. The cleaning solvent was deionized water. After three times of cleaning, γ-Fe 2 o 3 clusters and disperse them in 1 mL of deionized water for later use.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com