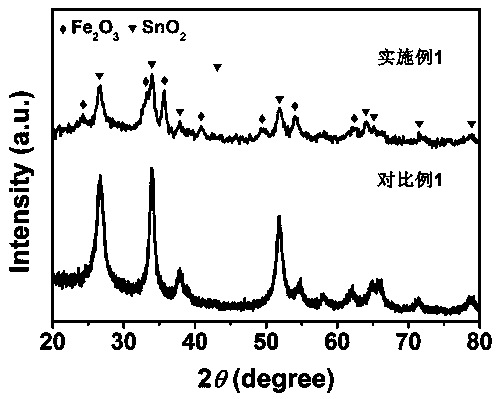

Preparation method of core-shell structure hollow microcube SnO2-Fe2O3 sensitive material and application of core-shell structure hollow microcube SnO2-Fe2O3 sensitive material

A technology of sno2-fe2o3 and core-shell structure, applied in nanotechnology for materials and surface science, analytical materials, nanotechnology for sensing, etc., to improve response sensitivity and selectivity, large specific surface area, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

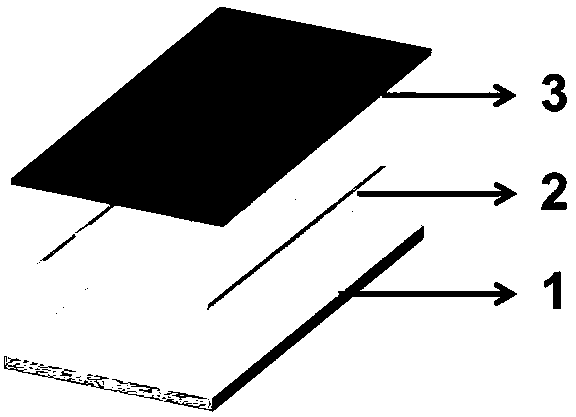

[0028] Preparation of hollow microcube SnO with core-shell structure 2 -Fe 2 o 3 Sensitive materials and making acetone gas sensor, the specific process is as follows:

[0029] At room temperature, mix 5 mL of ethanol and 20 mL of water and stir for 5 min as a solvent; then add 1 mmol of ZnCl in sequence 2 , 1 mmol SnCl 4 ·5H 2 O and 1 mmol sodium citrate, continue to stir until the solid is completely dissolved, continue to add 12.5 mmol of NaOH solid to react for 1 h, then add 40 mL, 3M NaOH solution dropwise to react for 0.5 h; centrifuge to collect the solid, and use deionized water repeatedly Washing; dry at 60°C, place in an air atmosphere at 750°C for calcination for 3 h, add 70 mg of solid collected after cooling to 30 mL, 1 M HCl solution for 15 min, centrifuge, wash and dry the precipitate to obtain SnO 2 Porous hollow micro-cube powder;

[0030] Take 40 mg SnO 2 Add porous hollow microcube powder into 10 mL deionized water, stir for 10 min to disperse evenly;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com