Magnetic chitosan medicine-carried nano particles and preparation method thereof

A drug-loading nanometer and nanoparticle technology, which is used in drug combinations, antitumor drugs, inorganic non-active ingredients, etc., can solve the problems of poor dispersion and large particle size, and achieve the effect of good dispersion and no agglomeration phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using the emulsion-crosslinking method, using chitosan for 5-fluorouracil and γ-Fe 2 o 3 The nanoparticles are wrapped to obtain spherical particles with a particle size of about 70-130nm. The specific steps are as follows:

[0024] (1), 100mg chitosan, 0.1mg γ-Fe 2 o 3 Nanoparticles (average particle diameter 20nm) mix with 0.5% dilute acetic acid solution (mass ratio) 2ml containing 40mg 5-fluorouracil, join in the 40ml liquid paraffin (volume ratio) that has been dissolved with 0.5% Span 80, in Stir at constant temperature for 2 hours at 35°C;

[0025] (2) Add 0.5ml of 2% trisodium citrate to the mixture, react for 30 minutes and solidify and precipitate particles; wash the obtained particles with petroleum ether and isopropanol respectively, and dry and store the particles in vacuum.

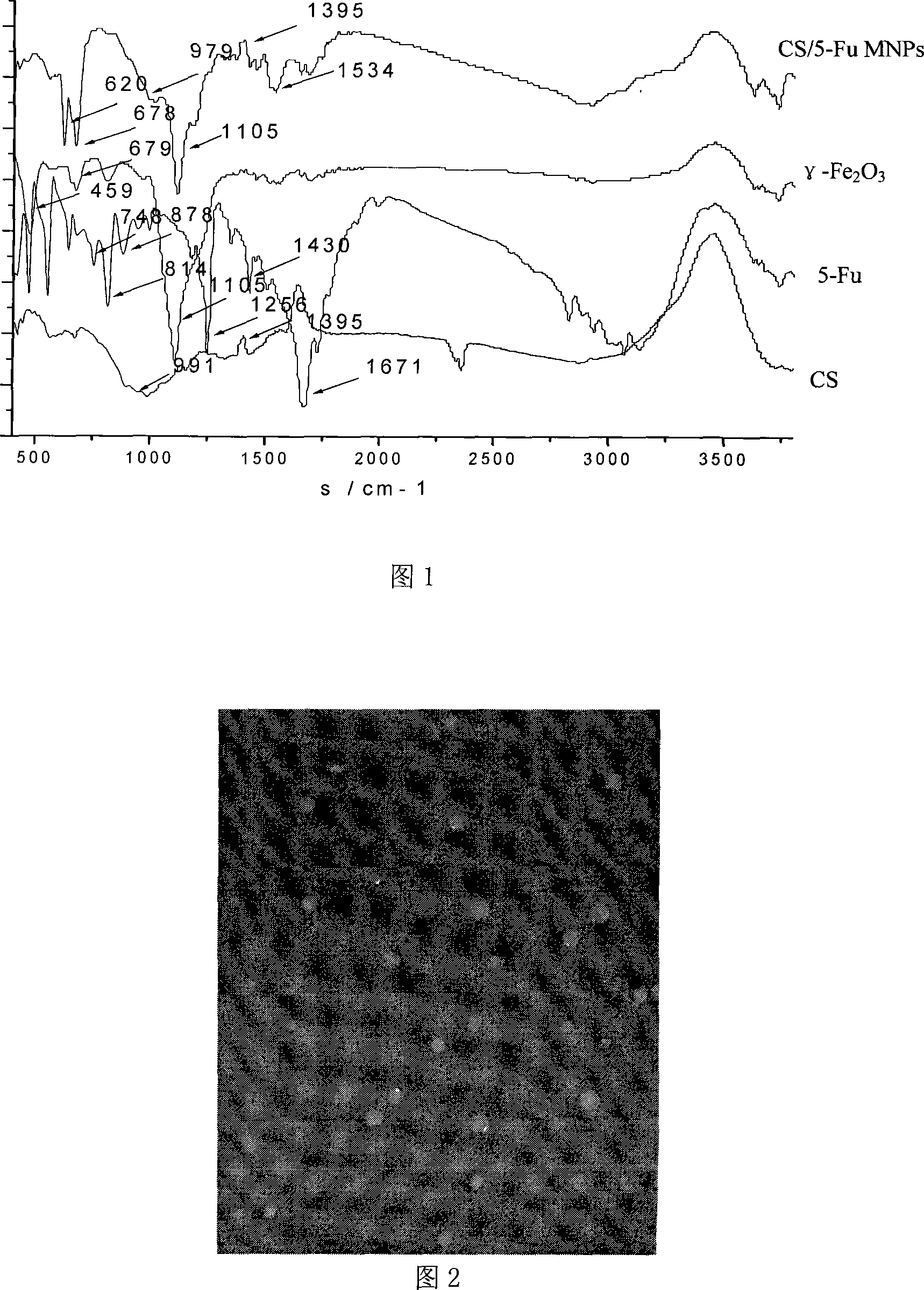

[0026] Particle characterization was carried out with testing instruments such as infrared spectrometer (FT-IR) and transmission electron microscope (TEM). The results are shown ...

Embodiment 2

[0030] (1), the chitosan of 120mg, 0.2mg γ-Fe 2 o 3 Nanoparticles (average particle diameter 20nm) mix with 0.5% dilute acetic acid solution (mass ratio) 2ml containing 50mg 5-fluorouracil, join in the 35ml liquid paraffin (volume ratio) that has been dissolved with 0.5% Span 80, in Stir at constant temperature for 2 hours at 35°C.

[0031] (2) Add 0.5ml of 2% trisodium citrate to the mixture, react for 30 minutes and solidify and precipitate particles; wash the obtained particles with petroleum ether and isopropanol respectively, and dry and store the particles in vacuum.

Embodiment 3

[0033] (1), 180mg chitosan, 0.1mg γ-Fe 2 o 3 Nanoparticles (average particle diameter 20nm) mix with 1% dilute acetic acid solution (mass ratio) 2ml containing 100mg 5-fluorouracil, join in the 40ml liquid paraffin (volume ratio) that has been dissolved with 0.4% Span 80, in Stir at constant temperature for 2 hours at 40°C. All the other steps are the same as in Example 1.

[0034] (2) Add 0.5ml of 2% trisodium citrate to the mixture, react for 30 minutes and solidify and precipitate particles; wash the obtained particles with petroleum ether and isopropanol respectively, and dry and store the particles in vacuum.

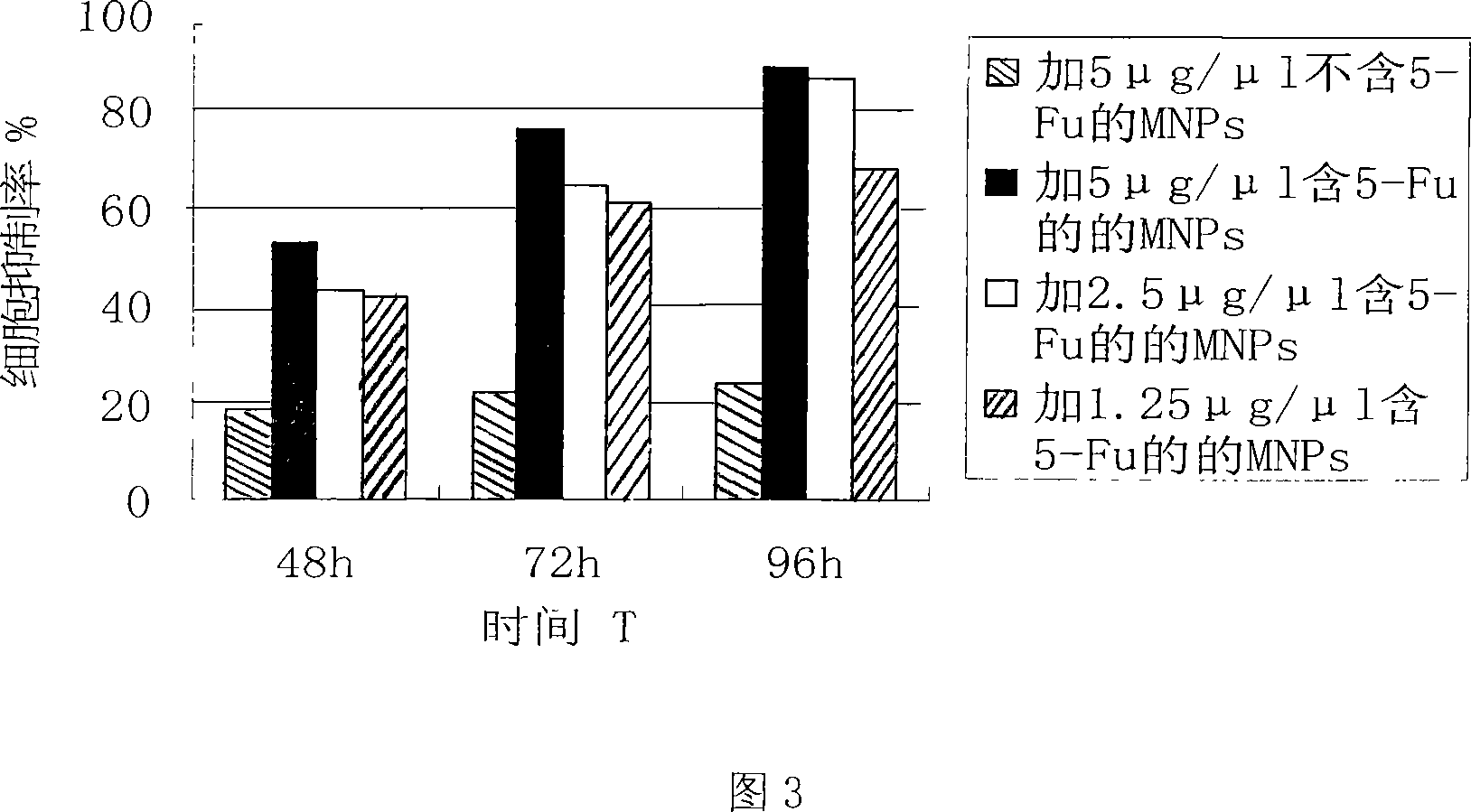

[0035] In Examples 1-3, the obtained CS / 5-Fu MNPs were dissolved in 0.1 mol / L hydrochloric acid solution, and the encapsulation efficiency of 5-Fu was determined to be 40%-50%, and the drug loading capacity of the particles was 15 %-25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com