Magnetic composite material and application thereof in regeneration and repair of bone tissues

A magnetic composite material, bone tissue regeneration technology, applied in tissue regeneration, medical science, prosthesis, etc., to achieve significant promotion effect, excellent biocompatibility, and promotion of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] γ-Fe 2 o 3 Preparation of nanoparticles

[0061] Prepare 500mL FeCl under nitrogen 3 (0.1M) and FeSO 4 (0.06M) aqueous solution, at room temperature, 200mL ammonia water (1.5M) was added dropwise to the aqueous solution and stirred vigorously. Thirty minutes later, the resulting Fe was collected using a magnetic field 3 o 4 nanoparticles and washed three times with water. Redisperse these particles in water, and oxidize them into γ-Fe in the air at 95°C under ventilated conditions 2 o 3 . γ-Fe 2 o 3 Mix and stir with DMSA (dimercaptosuccinic acid) in an aqueous solution of pH=2.7 for 1 hour to obtain superparamagnetic γ-Fe with DMSA attached to the surface 2 o 3 Nanoparticles.

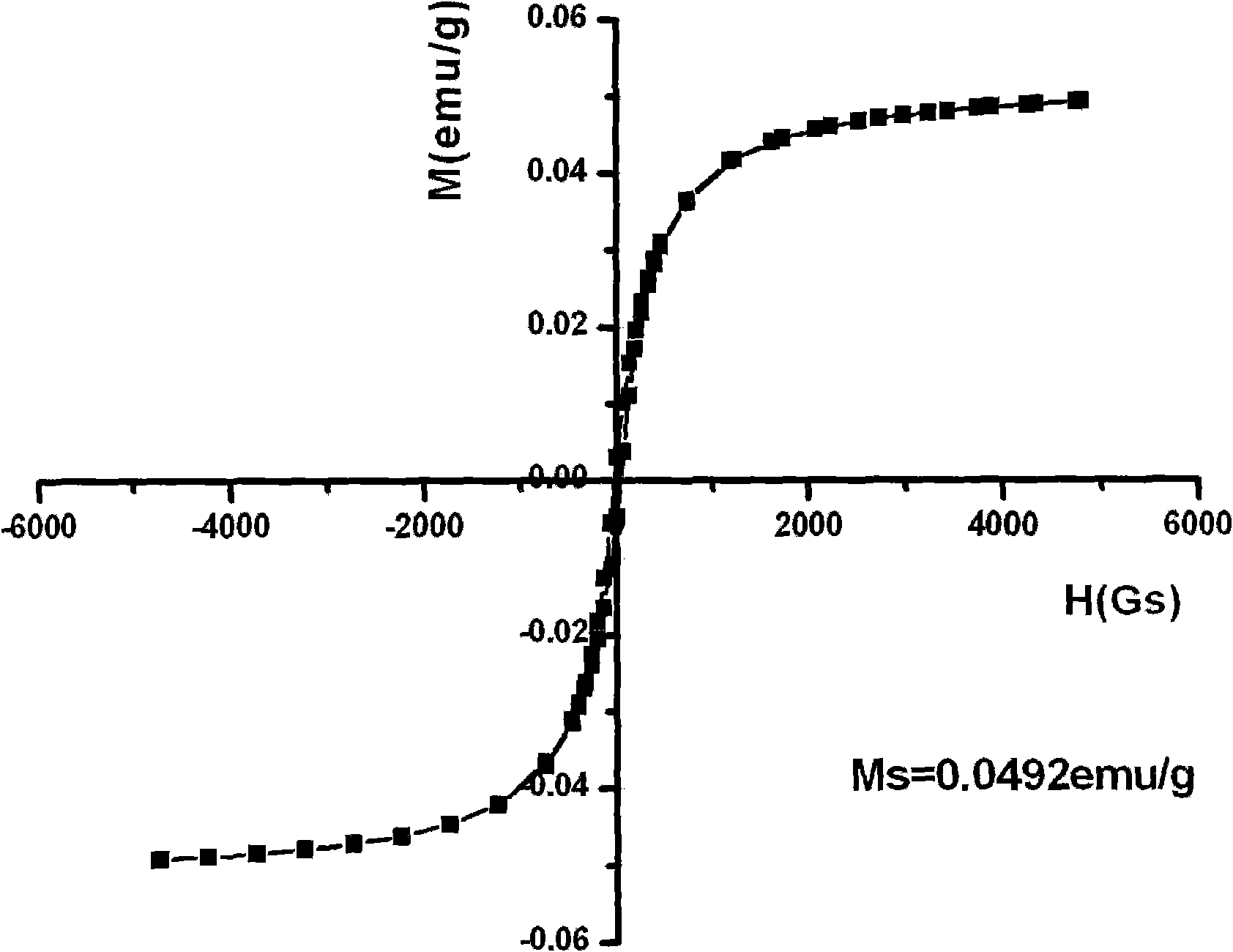

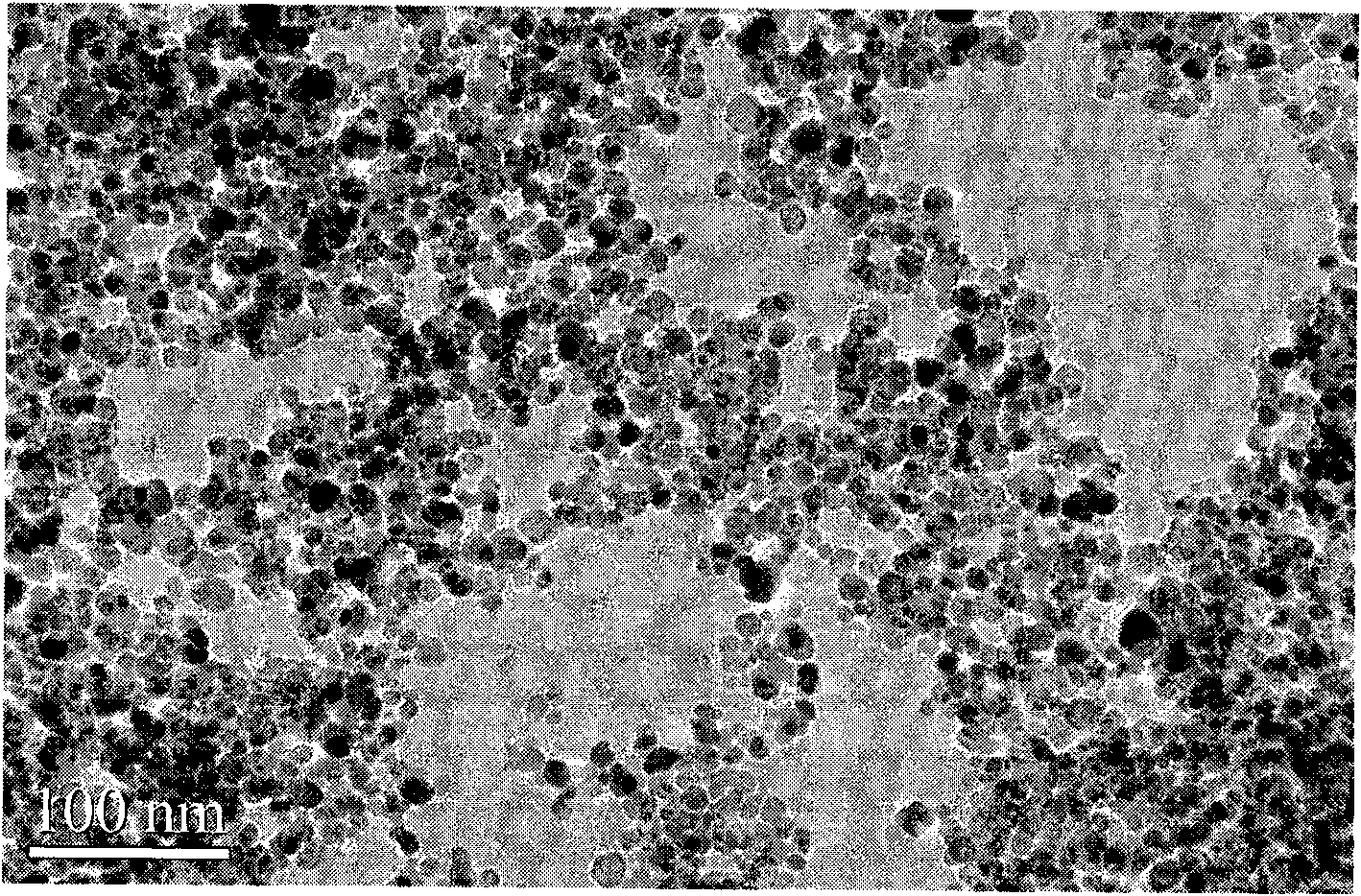

[0062] γ-Fe with DMSA attached to the surface 2 o 3 Nanoparticles (γ-Fe 2 o 3 / DMSA) particle size and morphology with transmission electron microscope observation and determination (TEM, JEOL, JEM-200EX), the results show that the particles are quasi-spherical, with an average ...

Embodiment 2

[0064] A, in 25ml small beaker, add 20ml dimethylacetamide (DMAc), the gamma-Fe of 0.5g drying prepared in embodiment 1 2 o3 Nanoparticles are dispersed in dimethylacetamide and dispersed uniformly by ultrasonic waves to obtain γ-Fe 2 o 3 a solution of nanoparticles;

[0065] B. In the above γ-Fe 2 o 3 Add 2g of dry nHA powder to the solution of nanoparticles, disperse evenly by ultrasonic wave, and obtain the solution containing γ-Fe 2 o 3 A solution of nanoparticles and nHA;

[0066] C. Containing γ-Fe in the above 2 o 3 Add 4 g of polylactic acid (PDLLA) to the solution of nanoparticles and nHA, and stir it with a stainless steel anchor stirrer controlled by a rotating motor (50 rpm) to form a fluid, well-mixed γ-Fe 2 o 3 / nHA / PDLLA / DMAc composite solution.

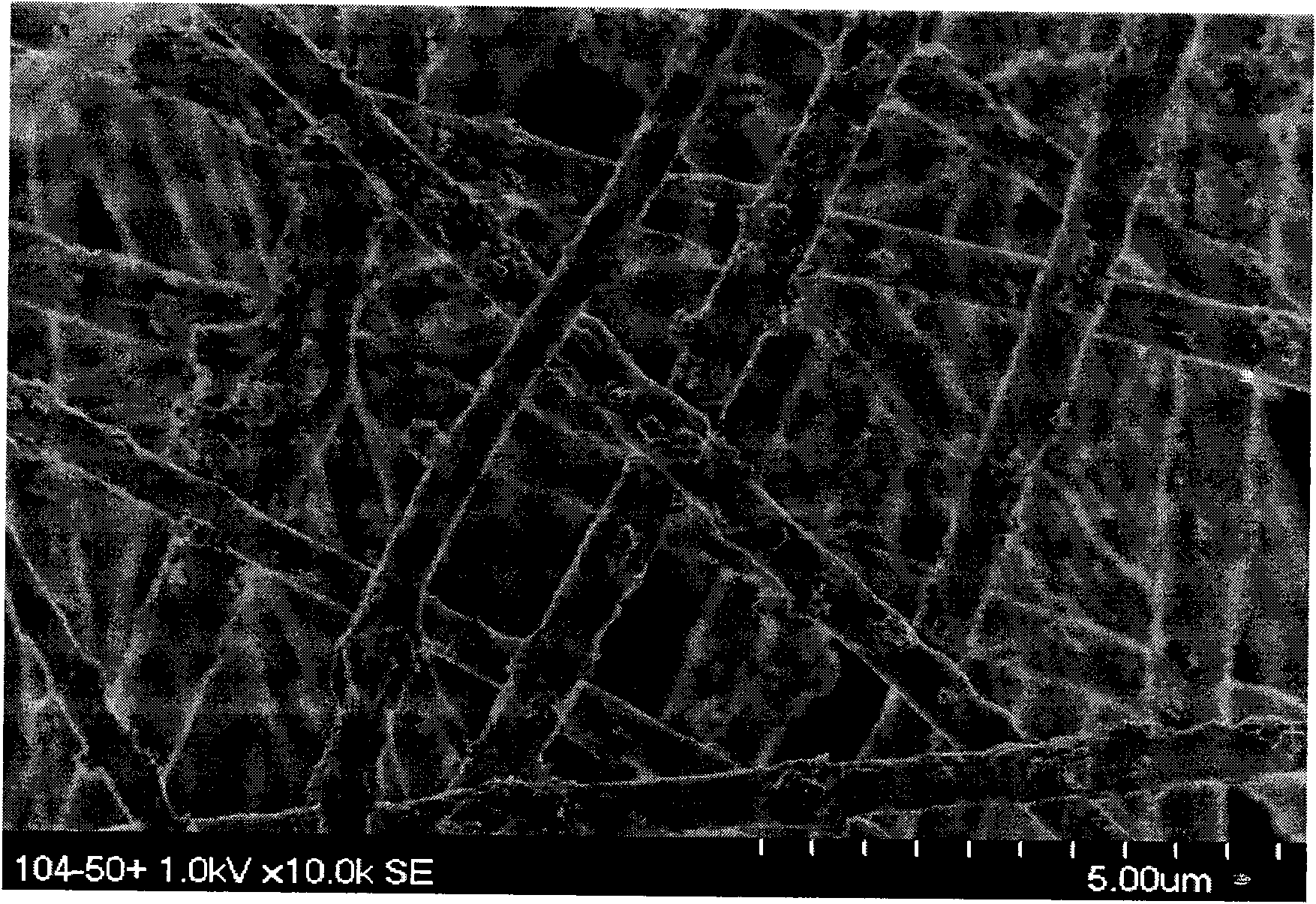

[0067] D. Add 2ml of the above composite material into the syringe pump, the nozzle is a 9# syringe needle, the nozzle is connected to the positive electrode of the high-voltage electrostatic generator, the r...

Embodiment 3

[0069] A, in 25ml small beaker, add 20ml dimethylacetamide (DMAc), the gamma-Fe of 0.5g drying prepared in embodiment 1 2 o 3 Nanoparticles are dispersed in dimethylacetamide and dispersed uniformly by ultrasonic waves to obtain γ-Fe 2 o 3 a solution of nanoparticles;

[0070] B. In the above γ-Fe 2 o 3 Add 2g of dry nHA powder to the solution of nanoparticles, disperse evenly by ultrasonic wave, and obtain the solution containing γ-Fe 2 o 3 A solution of nanoparticles and nHA;

[0071] C. Containing γ-Fe in the above 2 o 3 Add 2 g of polylactic acid (PDLLA) to the solution of nanoparticles and nHA, and stir it with a stainless steel anchor stirrer controlled by a rotating motor (50 rpm) to form γ-Fe with good fluidity and uniform mixing. 2 o 3 / nHA / PDLLA / DMAc composite solution.

[0072] D. Add 2ml of the above composite material into the syringe pump, the nozzle is a 9# syringe needle, the nozzle is connected to the positive electrode of the high-voltage electrost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com