A kind of preparation method of micron superparamagnetic ferric oxide microsphere

A ferric tetroxide, superparamagnetic technology, applied in the direction of iron oxide/iron hydroxide, ferrous oxide, etc., can solve problems such as difficulties, and achieve good dispersion, uniform particle size, and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

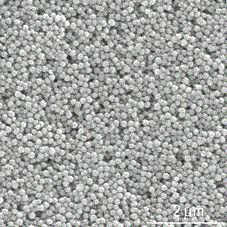

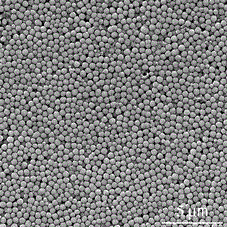

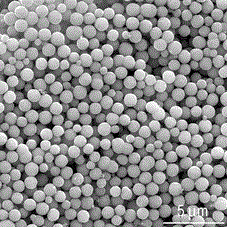

[0017] A method for preparing micron-sized superparamagnetic ferric oxide microspheres, comprising the following steps: ① adding ferric chloride hexahydrate, sodium formate and 20wt% polyacrylic acid solution into ethylene glycol, and stirring evenly to obtain a mixed solution A , wherein the molar ratio of ferric chloride hexahydrate to sodium formate is 1:9, the molar ratio of ferric chloride hexahydrate to ethylene glycol is 1:500, and the volume ratio of ethylene glycol to 20wt% polyacrylic acid solution is 40 : 1; ② Ferric chloride hexahydrate and sodium acetate are added to ethylene glycol, and stirred evenly to obtain a mixed solution B, wherein the molar ratio of ferric chloride hexahydrate and sodium acetate is 1: 7, trichlorohydrin hexahydrate The molar ratio of iron oxide to ethylene glycol is 1:150; ③ transfer the mixed solution A to a high-pressure reactor with mechanical stirring, the mechanical stirring speed is 200 rpm, and the high-pressure reactor is heated to...

Embodiment 2

[0020] A method for preparing micron-sized superparamagnetic ferric oxide microspheres, comprising the following steps: ① adding ferric chloride hexahydrate, sodium formate and 10wt% polyacrylic acid solution into ethylene glycol, and stirring evenly to obtain a mixed solution A , wherein the molar ratio of ferric chloride hexahydrate to sodium formate is 1:8, the molar ratio of ferric chloride hexahydrate to ethylene glycol is 1:400, and the volume ratio of ethylene glycol to 10wt% polyacrylic acid solution is 30 : 1; ② ferric chloride hexahydrate and sodium acetate are added to ethylene glycol, and stirred evenly to obtain a mixed solution B, wherein the molar ratio of ferric chloride hexahydrate and sodium acetate is 1: 6, and trichlorohydrin hexahydrate The molar ratio of iron oxide to ethylene glycol is 1:100; ③ transfer the mixed solution A to a high-pressure reactor with mechanical stirring, the mechanical stirring speed is 150 rpm, and the high-pressure reactor is heate...

Embodiment 3

[0022] A method for preparing micron-sized superparamagnetic ferric oxide microspheres, comprising the following steps: ① adding ferric chloride hexahydrate, sodium formate and 30wt% polyacrylic acid solution into ethylene glycol, and stirring evenly to obtain a mixed solution A , wherein the molar ratio of ferric chloride hexahydrate to sodium formate is 1:10, the molar ratio of ferric chloride hexahydrate to ethylene glycol is 1:300, and the volume ratio of ethylene glycol to 30wt% polyacrylic acid solution is 50 : 1; ② Ferric chloride hexahydrate and sodium acetate are added to ethylene glycol, and stirred evenly to obtain a mixed solution B, wherein the molar ratio of ferric chloride hexahydrate and sodium acetate is 1: 8, trichlorohydrin hexahydrate The molar ratio of iron oxide to ethylene glycol is 1:50; ③ transfer the mixed solution A to a high-pressure reactor with mechanical stirring, the mechanical stirring speed is 300 rpm, and the high-pressure reactor is heated to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com