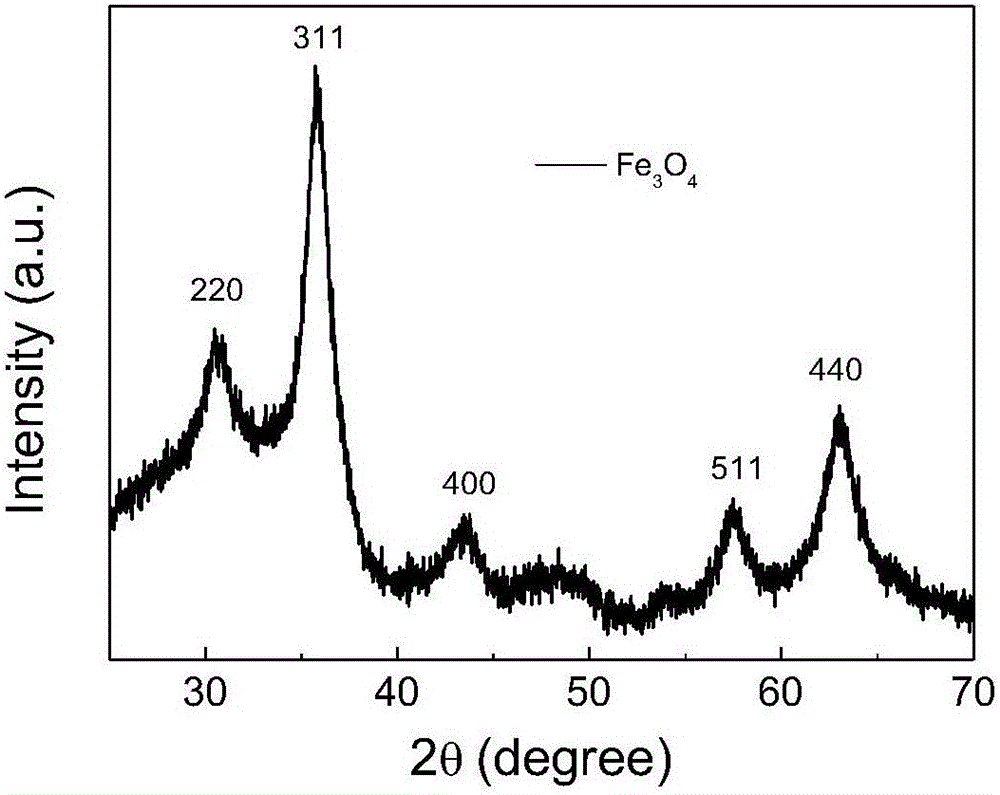

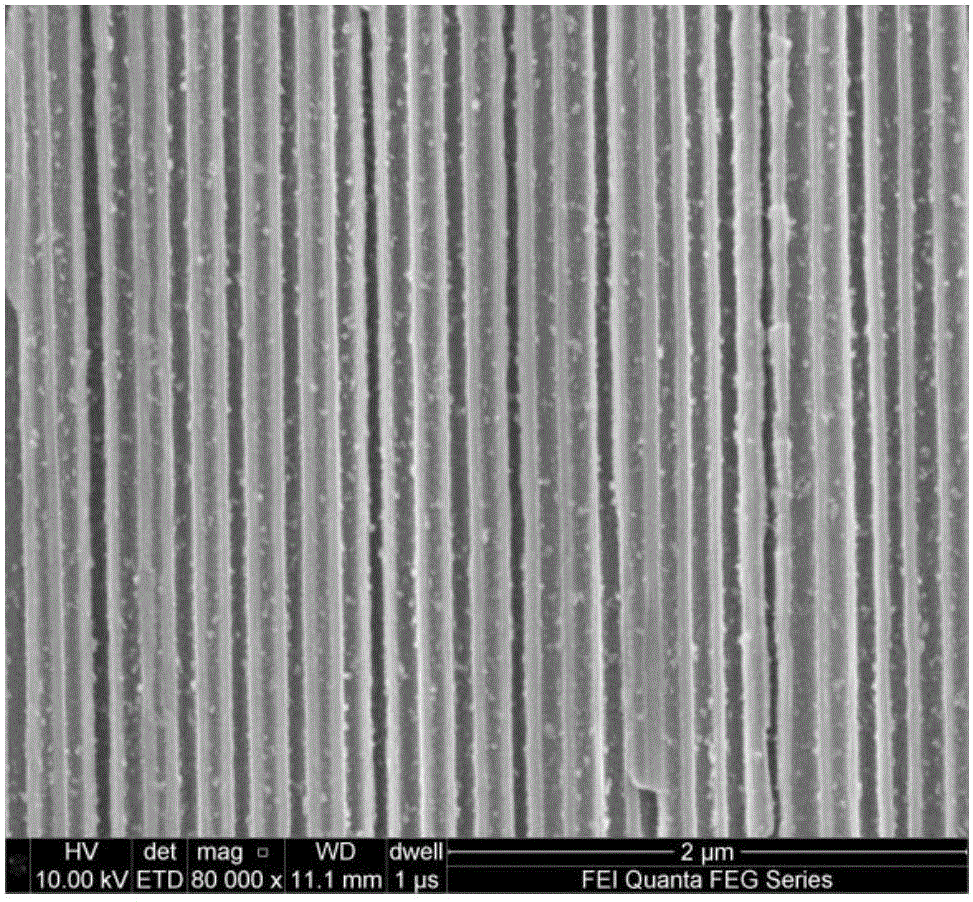

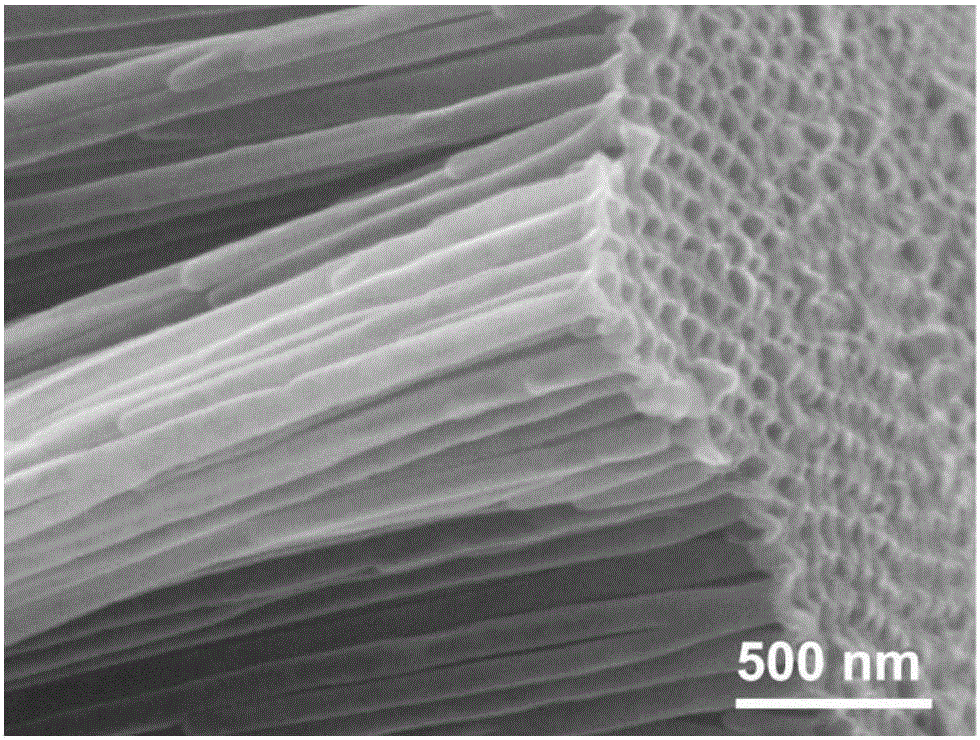

An in situ preparation of superparamagnetic Fe by atomic layer deposition 3 o 4 nanotube array method

A technology of atomic layer deposition and nanotube array, applied in nanotechnology, coating, metal material coating process, etc., can solve the problems of cumbersome process, inability to obtain neatly arranged superparamagnetic Fe nanotube array, complexity, etc., to achieve The effect of wide source of raw materials, precise and controllable wall thickness, and highly uniform thickness and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An in-situ preparation of superparamagnetic Fe by atomic layer deposition 3 o 4 A method for nanotube arrays, comprising the steps of:

[0036] a. AAO template substrate preparation:

[0037] Clean the AAO substrate required for the experiment in the following order: ultrasonically clean with acetone for 10 minutes, pour out the acetone, clean with absolute ethanol for 10 minutes, pour out the absolute ethanol, and finally use deionized water to repeatedly ultrasonically clean for 3 times. 5 minutes each time. After cleaning, take out the AAO substrate and dry it with nitrogen gas before sending it into the vacuum reaction chamber for use.

[0038] b. Put the ferrocene source into the solid source heating source bottle of the ALD equipment, pre-extract the source bottle to remove the air introduced during the source loading process, and set the heating temperature of the source bottle to heat the source until The vapor pressure of each pulse is stabilized. Since fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com