Method for preparing high thermal-stability clay mineral-iron oxide red hybrid pigment by co-precipitation technology

A clay mineral and co-precipitation technology, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of uneconomical application and harsh experimental conditions, and achieve low price, easy large-scale production, and economical improvement value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

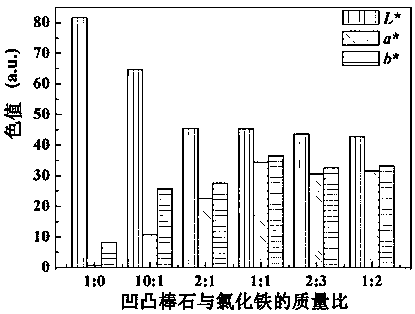

Embodiment 1

[0030] The attapulgite ore is crushed and crushed to 200 mesh. Weigh 10 g and disperse in 100 mL aqueous solution containing 10 g ferric chloride, add 5 mol / L sodium hydroxide drop by drop after fully stirring and sonicating, adjust the pH to about 8, continue to stir and react for 4 h; The solid product was obtained by centrifugation, washed, dried at 105°C until the water content was 10%, and then directly transferred to a muffle furnace for calcination. The heating rate was controlled at 10°C / min, and crystallized at 500°C for 2 h; after calcination, it was crushed The attapulgite-iron red hybrid pigment was obtained through the treatment. The color values L*, a*, and b* of the hybrid pigment are 43.8, 33.9, and 36.0, respectively.

Embodiment 2

[0032]The attapulgite mineral powder is crushed and crushed to 200 mesh. Weigh 10 g and disperse it in 100 mL of aqueous solution containing 5 g of ferrous ammonium sulfate, stir and ultrasonically add 8 mol / L urea drop by drop, adjust the pH to about 10, and continue to stir for 2 h. At the end of the reaction, the solid product was centrifuged and dried directly in an oven at 80 °C until the water content was about 1%, and then transferred to a muffle furnace for calcination at a controlled heating rate of 1 °C / min and crystallized at 400 °C for 1 h. The attapulgite ore-iron red hybrid pigment is obtained by pulverizing after calcining. The color values L*, a*, and b* of the hybrid pigment are 45.1, 21.8, and 25.1, respectively.

Embodiment 3

[0034] Sepiolite ore powder is crushed and crushed to 200 mesh. Weigh 10 g and disperse in 100 mL of aqueous solution containing 20 g of ferrous nitrate, stir and ultrasonically add 6 mol / L hexamethylenetetramine dropwise, adjust the pH to about 10, and continue to stir for 4 h. At the end of the reaction, the solid product was centrifuged. After washing, it was dried in an oven at 80 °C until the water content was about 30%, and then transferred to a muffle furnace for calcination. The heating rate was controlled at 5 °C / min, and crystallization was carried out at 200 °C for 4 h. After calcining, pulverize to obtain sepiolite-iron red hybrid pigment. The color values L*, a*, and b* of the hybrid pigment are 41.6, 32.9, and 35.1, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com