Double-aerated aerobic bidirectional two-way sludge backflow high-efficiency reactor with two sludge filter areas

A technology for returning sludge and sludge filtration, applied in water/sludge/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of large amount of residual sludge and reduction of sludge age , Unable to guarantee the growth of sludge age and other problems, to achieve the effect of high COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

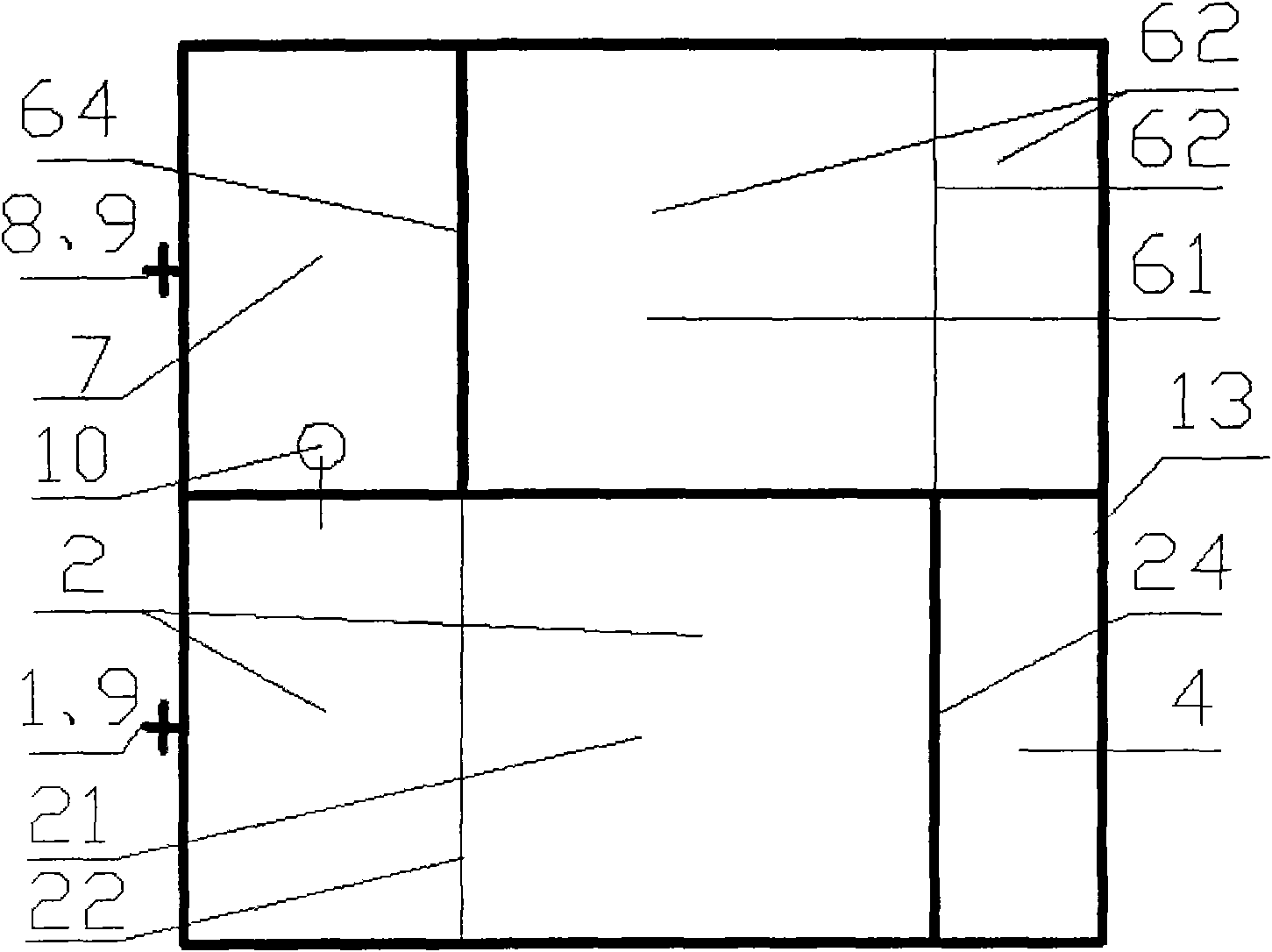

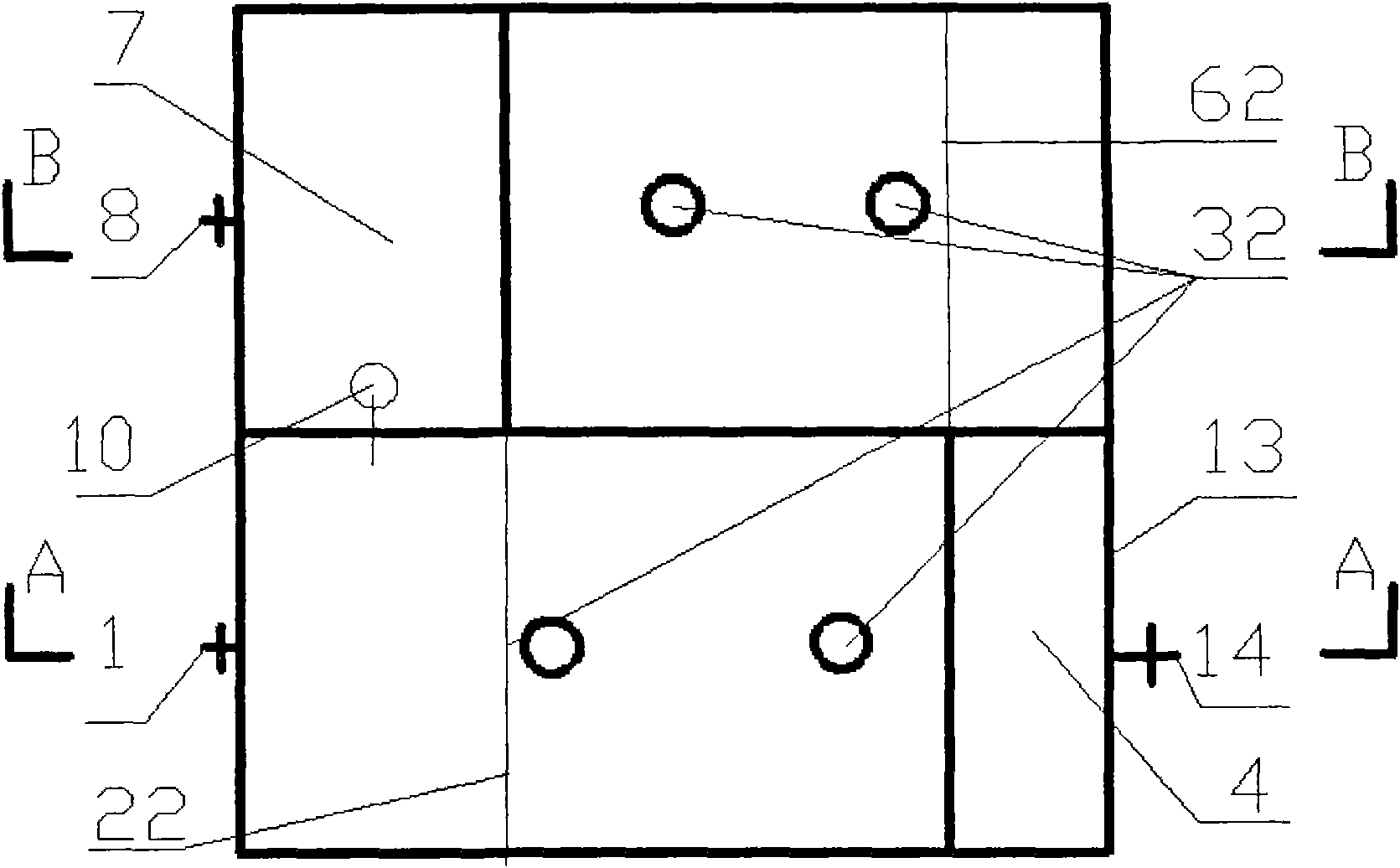

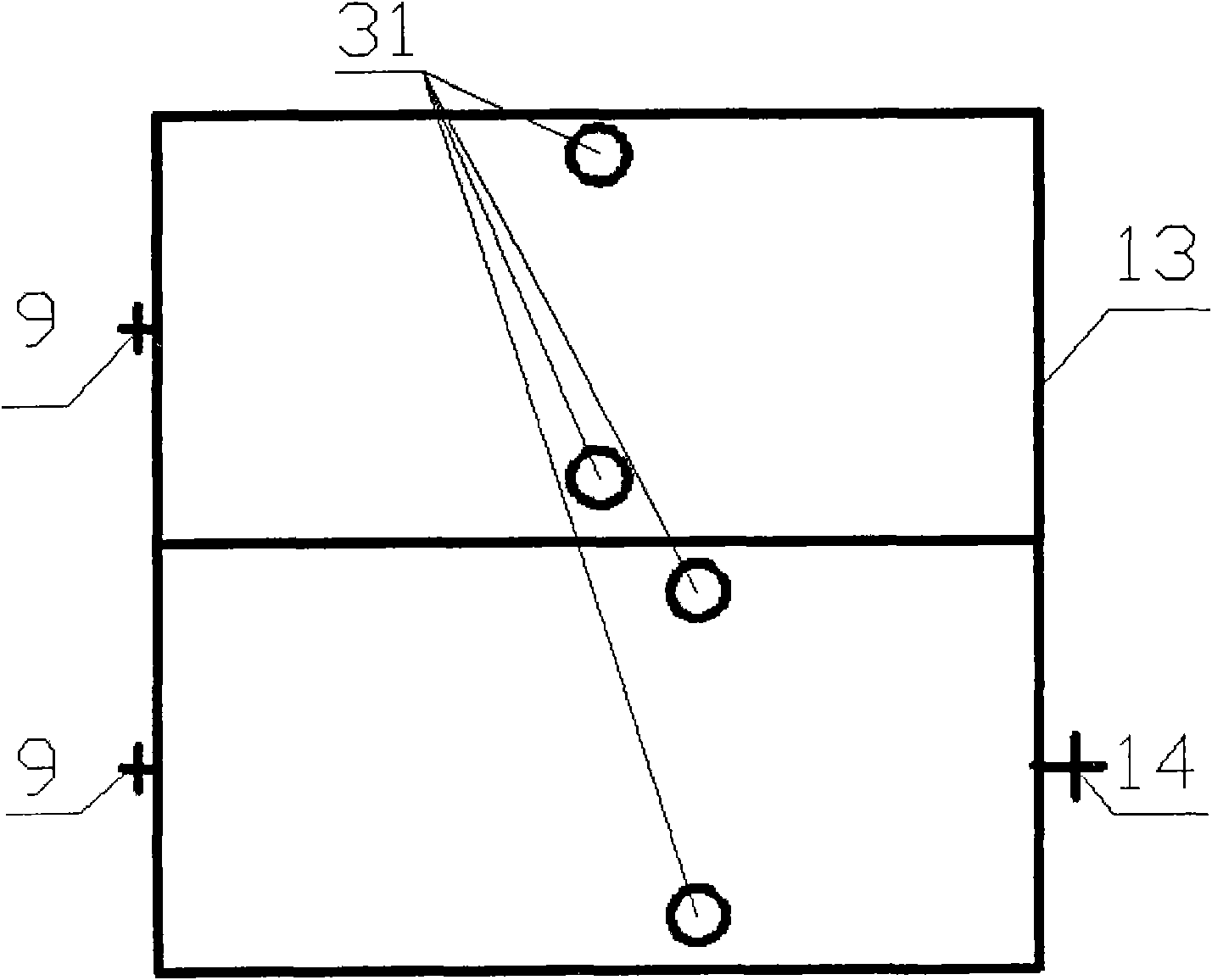

[0014]The high-efficiency reactor of double aerated aerobic two-way return sludge double sludge filtration zone of the present invention, it has tank body 13, is divided into two compartments in the tank body 13, is respectively provided with the first aeration zone 2, the first The sludge filter zone 4, the second aeration zone 6 and the second sludge filter zone 7 are provided with a water inlet pipe 1 on one side of the tank body 13, and the water inlet pipe 1 enters the first aeration zone 2, and the first aeration zone The partition plate 22 of the zone is connected with the side wall of the pool body 13 and the first longitudinal partition 24, and the first aeration zone 2 is divided into the aeration zone 21 above the first aeration zone by the partition plate 22 of the first aeration zone. And the aeration zone 23 below the first aeration zone, the dividing plate 22 of the first aeration zone has a gap on the water inlet side of the pool body 13 and the corresponding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com