Preparation method of zinc oxide base red light nano material

A nano-material, zinc oxide-based technology, applied in the field of nano-materials, can solve the problems of low luminous efficiency of ZnO, large concentration quenching, difficult application, etc., and achieve the effect of uniform shape, uniform distribution and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

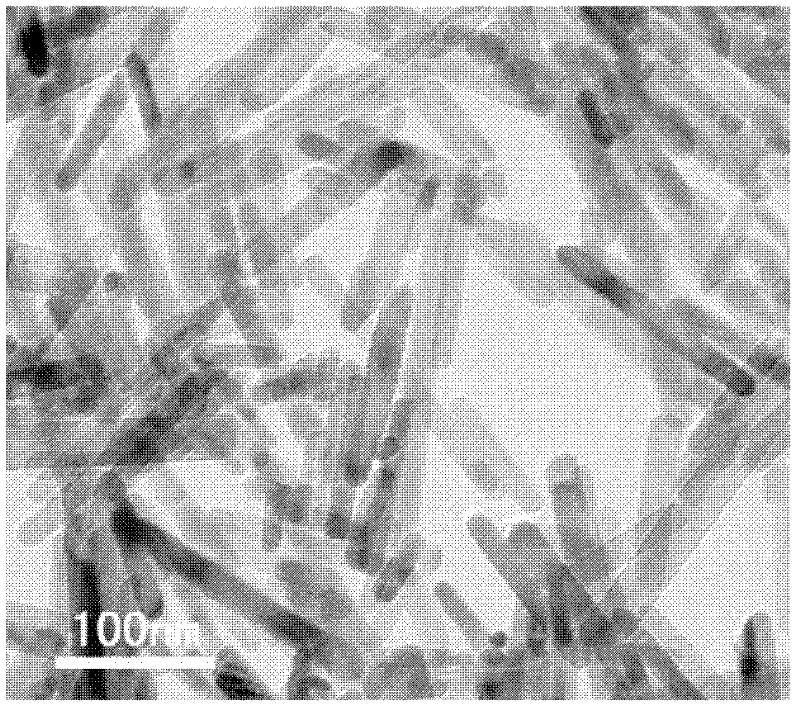

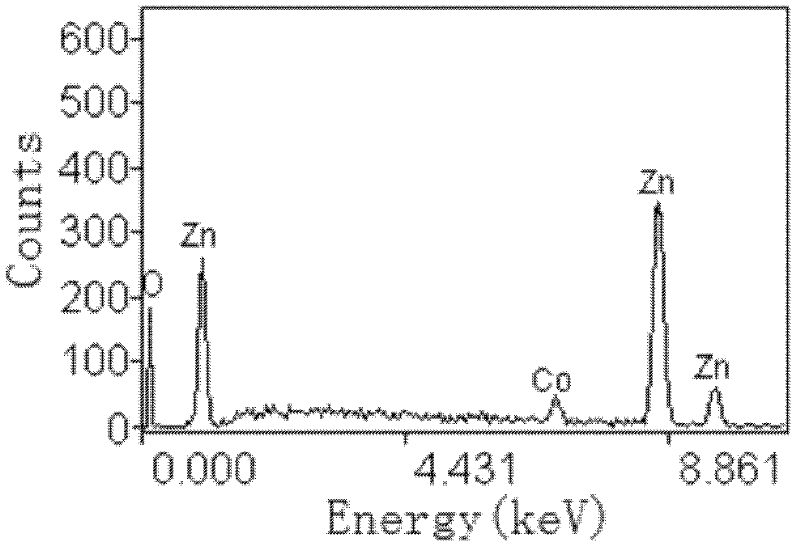

[0021] Get 5mmol of zinc acetate (Zn(Ac) 2 2H 2 O) and 0.25 mmol of cobalt acetate (Co(Ac) 2 4H 2 O) After dissolving in 100ml of absolute ethanol, add 40ml of ethanol solution of sodium hydroxide dropwise to this solution (the concentration of sodium hydroxide is 0.8mol / L; the dripping speed is 2ml / minute), and continue to drip while adding Stir until the solution turns a solid blue color. Finally, 35ml of polyethylene glycol was added, and after a little stirring, the above solution was transferred into a high-temperature and high-pressure reactor (based on a filling degree of 75%-80%). Seal the reaction kettle, place it in an environment of 140°C, take it out after 16 hours of heat preservation, remove the waste liquid in the reaction kettle, take the sediment in it, wash it with deionized water for 8 to 10 times, and dry the obtained green The powder is zinc oxide nanorods with a cobalt doping content of 5%. Its transmission electron microscope morphology and EDS ener...

Embodiment 2

[0023] Get 5mmol of zinc acetate (Zn(Ac) 2 2H 2 O) and 0.125 mmol of cobalt acetate (Co(Ac) 2 4H 2 O) After dissolving in 100ml of absolute ethanol, add 40ml of ethanol solution of sodium hydroxide dropwise to this solution (the concentration of sodium hydroxide is 0.8mol / L; the dropping speed is 2ml / minute), and continue to carry out while dropping Stir until the solution turns a solid blue color. Finally, 35ml of polyethylene glycol was added, and after a little stirring, the above solution was transferred into a high-temperature and high-pressure reactor (based on a filling degree of 75%-80%). Seal the reaction kettle, place it in an environment of 140°C, take it out after 16 hours of heat preservation, remove the waste liquid in the reaction kettle, take the sediment in it, wash it with deionized water for 8 to 10 times, and dry the obtained green The powder is zinc oxide nanorods with a cobalt doping content of 2.5%.

[0024]

Embodiment 3

[0026] Get 5mmol of zinc acetate (Zn(Ac) 2 2H 2 O) and 0.05 mmol of cobalt acetate (Co(Ac) 2 4H 2 O) After dissolving in 100ml of absolute ethanol, add 40ml of ethanol solution of sodium hydroxide dropwise to this solution (the concentration of sodium hydroxide is 0.8mol / L; the dropping speed is 2ml / minute), and continue to carry out while dropping Stir until the solution turns a solid blue color. Finally, 35ml of polyethylene glycol was added, and after a little stirring, the above solution was transferred into a high-temperature and high-pressure reactor (based on a filling degree of 75%-80%). Seal the reaction kettle, place it in an environment of 140°C, take it out after 16 hours of heat preservation, remove the waste liquid in the reaction kettle, take the sediment in it, wash it with deionized water for 8 to 10 times, and dry the obtained green The powder is zinc oxide nanorods with a cobalt doping content of 1%.

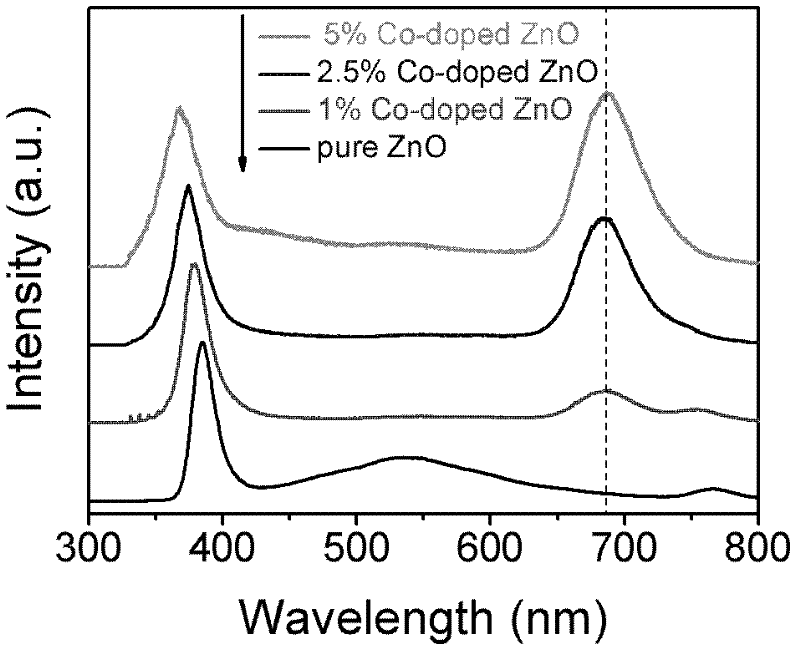

[0027] Use the laser of 325nm wavelength to excite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com