Lithium-rich multi-component lithium ion battery positive pole material and preparation method thereof

A lithium-ion battery and multi-component compounding technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as high cost, complicated preparation process, and difficulty in large-scale application, and achieve low production cost, simple preparation process, and high economy. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

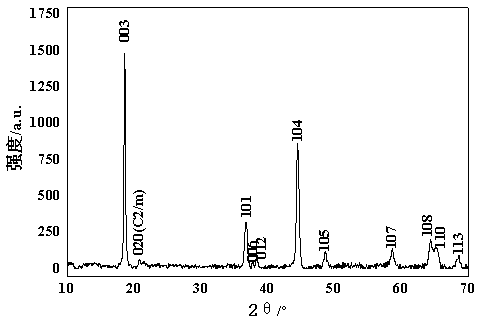

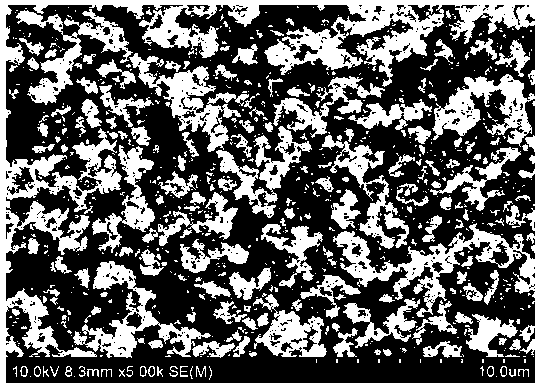

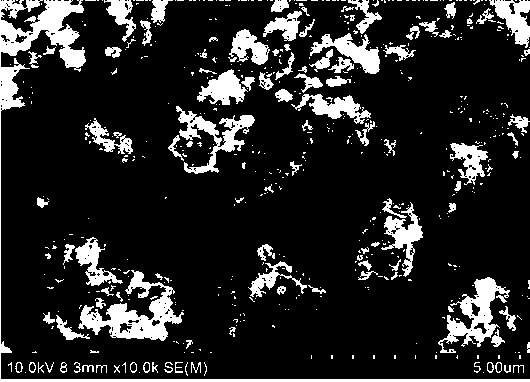

[0068] A lithium-rich multi-element composite lithium-ion battery positive electrode material, its molecular formula is Li 1.13 Ni 0.20 co 0.20 mn 0.47 o 2 .

[0069] The anode material Li 1.13 Ni 0.20 co 0.20 mn 0.47 o 2 The preparation method specifically comprises the following steps:

[0070] (1) Completely dissolve 0.5441g lithium acetate and 0.6536g manganese acetate in 50 ml ethanol solution, and form solution 1 after standing for 0.5h;

[0071] The amount of above-mentioned lithium acetate and manganese acetate is calculated by molar ratio, namely lithium acetate: manganese acetate is 0.53:0.27;

[0072] (2) Completely dissolve 0.6121g lithium acetate, 0.4977g nickel acetate, 0.4982g cobalt acetate and 0.4902g manganese acetate in 50 ml ethanol solution, and form solution 2 after standing for 0.5h;

[0073] The amount of above-mentioned lithium acetate, nickel acetate, cobalt acetate and manganese acetate is calculated by molar ratio, namely lithium acetate:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com