Preparation method of cobaltosic oxide composite graphene three-dimensional aerogel

A technology of composite graphene and cobalt tetroxide, applied in the field of materials science, can solve the problems of poor thermal stability and low specific surface area, and achieve the effects of good thermal stability, large specific surface area and strong shape controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

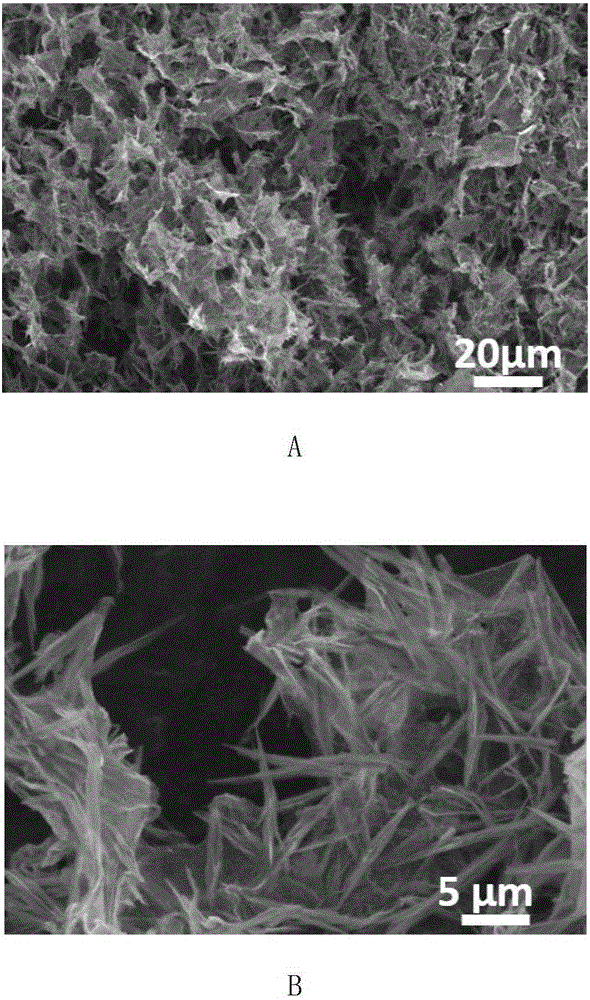

Embodiment 1

[0029] A preparation method of tricobalt tetroxide composite graphene three-dimensional airgel, comprising the steps of:

[0030] (1), a step for preparing graphene oxide, at room temperature, 5g graphite flakes, 1gNaNO 3 Add it to a 1L beaker one by one, mix well and slowly add 250g concentrated sulfuric acid, stir for 30-40min, then add 20gKMnO at a rate of 1g / min 4 , and then continue to stir until the solution turns purple, place it for 5 days until the graphite flakes are basically oxidized completely, then add 500mL of water to dilute, and then add 20g of H2O with a volume percentage concentration of 30%. 2 o 2 aqueous solution, stirred evenly, until the solution changed from purple to yellow during the stirring process, and a large number of bubbles were generated in the process to obtain a reaction solution; the graphite flakes, NaNO 3 , concentrated sulfuric acid, KMnO 4 、H 2 o 2 The amount, calculated by mass ratio, that is, graphite flakes: NaNO 3 : concentrat...

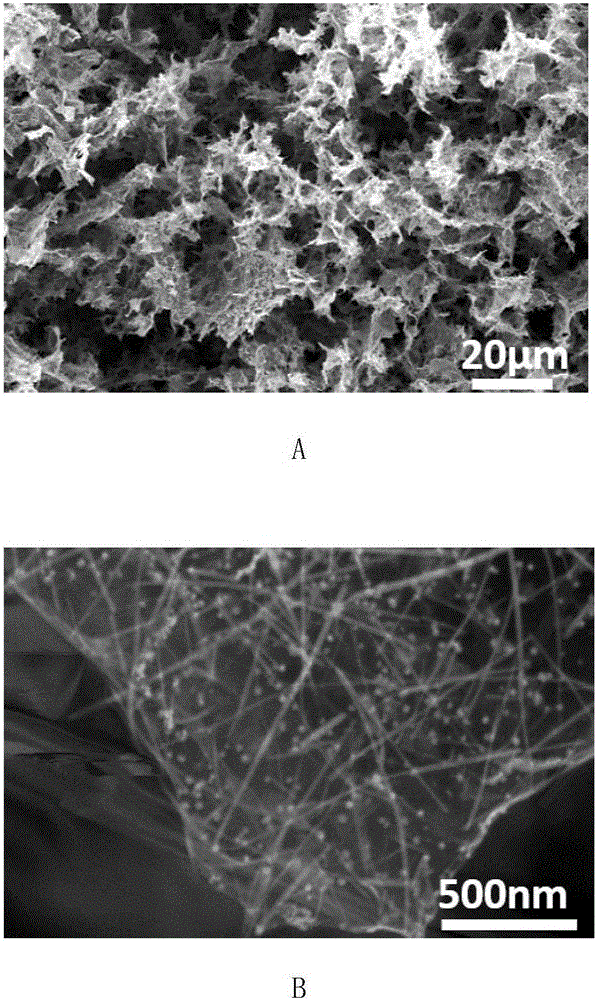

Embodiment 2

[0037] A preparation method of tricobalt tetroxide composite graphene three-dimensional airgel, specifically comprising the steps of:

[0038] 1) A step for preparing graphene oxide, at room temperature, 5g graphite sheet, 1gNaNO 3 Add it to a 1L beaker one by one, mix well and slowly add 250g concentrated sulfuric acid, stir for 30-40min, then add 20gKMnO at a rate of 1g / min 4 , and then continue to stir until the solution turns purple, place it for 5 days until the graphite flakes are basically oxidized completely, then add 500mL of water to dilute, and then add 20g of H2O with a volume percentage concentration of 30%. 2 o 2 aqueous solution, stirred evenly, until the solution changed from purple to yellow during the stirring process, and a large number of bubbles were generated in the process to obtain a reaction solution; the graphite flakes, NaNO 3 , concentrated sulfuric acid, KMnO 4 、H 2 o 2 The amount, calculated by mass ratio, that is, graphite flakes: NaNO 3 : ...

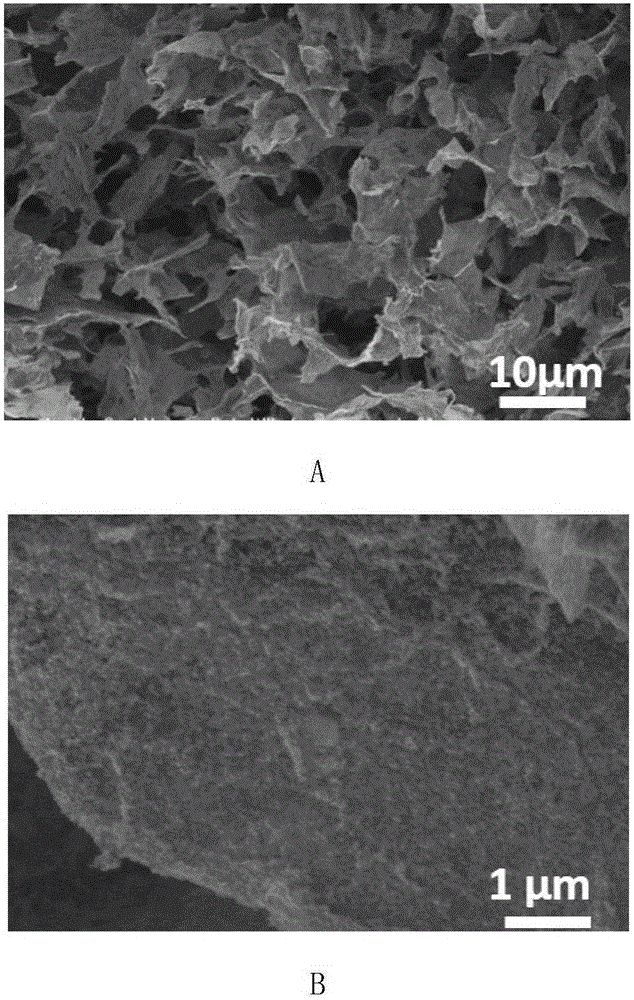

Embodiment 3

[0045] A preparation method of tricobalt tetroxide composite graphene three-dimensional airgel, specifically comprising the steps of:

[0046] 1) A step for preparing graphene oxide, at room temperature, 5g graphite sheet, 1gNaNO 3 Add it to a 1L beaker one by one, mix well and slowly add 250g concentrated sulfuric acid, stir for 30-40min, then add 20gKMnO at a rate of 1g / min 4 , and then continue to stir until the solution turns purple, place it for 5 days until the graphite flakes are basically oxidized completely, then add 500mL of water to dilute, and then add 20g of H2O with a volume percentage concentration of 30%. 2 o 2 aqueous solution, stirred evenly, until the solution changed from purple to yellow during the stirring process, and a large number of bubbles were generated in the process to obtain a reaction solution; the graphite flakes, NaNO 3 , concentrated sulfuric acid, KMnO 4 、H 2 o 2 The amount, calculated by mass ratio, that is, graphite flakes: NaNO 3 : ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com