Synthesis method of ZIF-67 derived CoO

A ZIF-67, 2·6H2O technology, applied in the direction of cobalt oxide/cobalt hydroxide, etc., to achieve the effect of good stability and repeatability, strong operability and practicability, and high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below by means of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

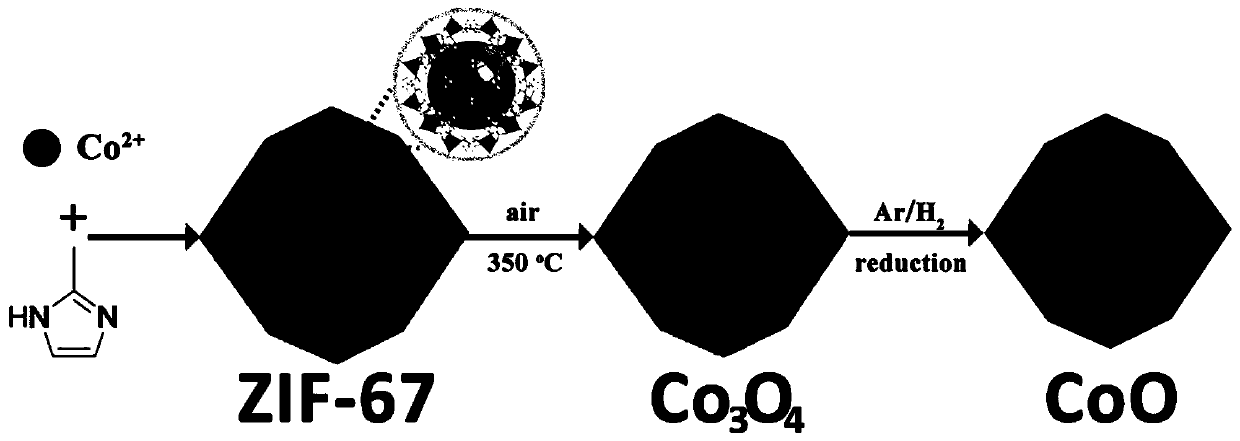

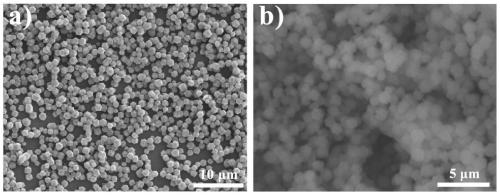

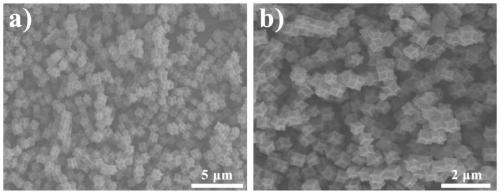

[0018] The invention discloses a method for preparing CoO microparticles. The method takes ZIF-67 as a template and adopts two-step chemical vapor deposition (CVD) to obtain polydisperse Co 3 o 4 , and then coated with PVP, and annealed to obtain CoO microparticles with shape and pore size retention; in other words, the present invention is the first to prepare CoO microparticles derived from metal-organic frameworks with shape retention.

[0019] The preparation method of CoO microparticles according to the present invention comprises the following steps:

[0020] (1) if figure 1 Shown, the schematic flow chart of the present invention. Will Co(NO 3 ) 2 ·6H 2 O and 2-methylimidazole were dissolved in methanol respectively, stirred at 800rpm / s for 5min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com