Preparation method for graphene@CoAl-LDH composite electrode material

A composite electrode and graphene technology, applied in hybrid capacitor electrodes and other directions, can solve problems such as easy agglomeration and poor conductivity of bimetallic oxides, achieve high specific capacitance, overcome poor cycle performance, and excellent charge and discharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

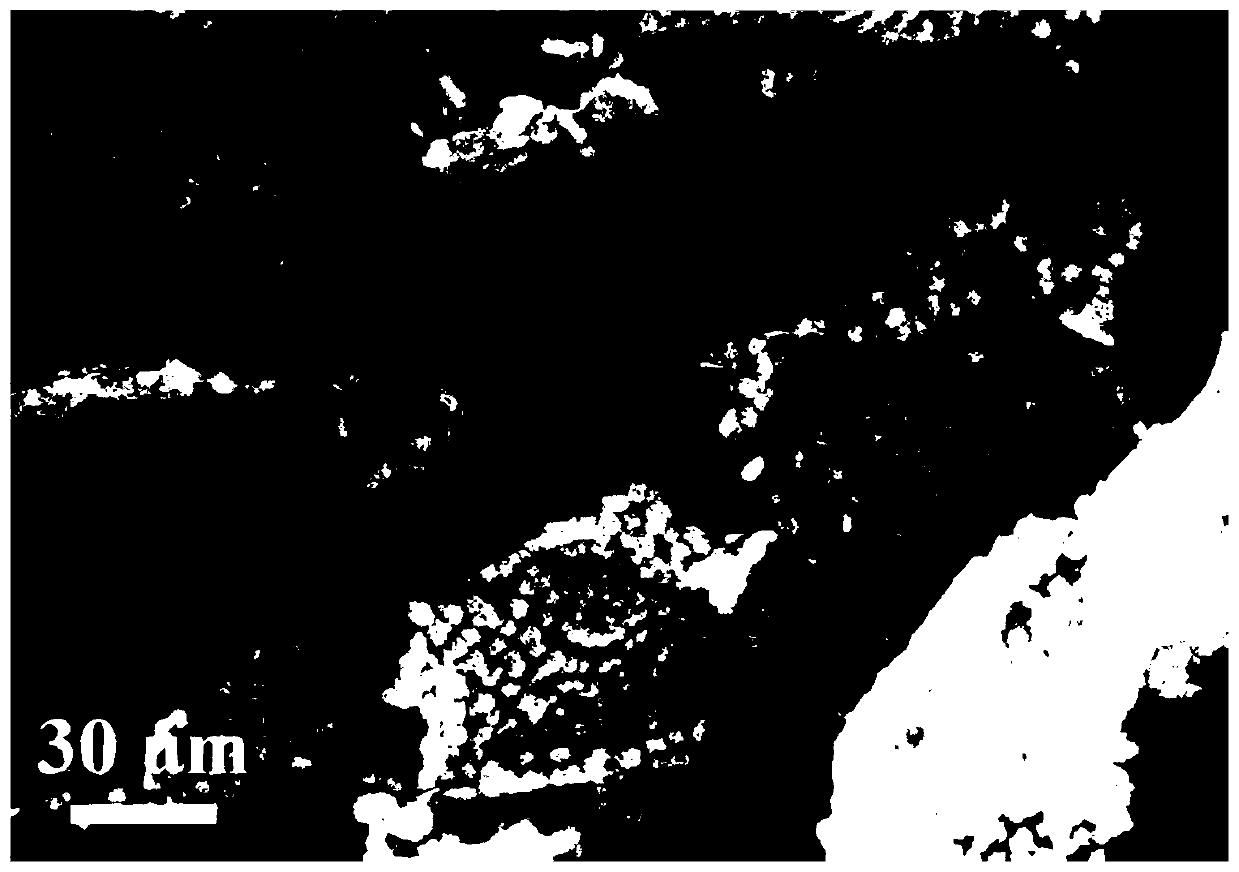

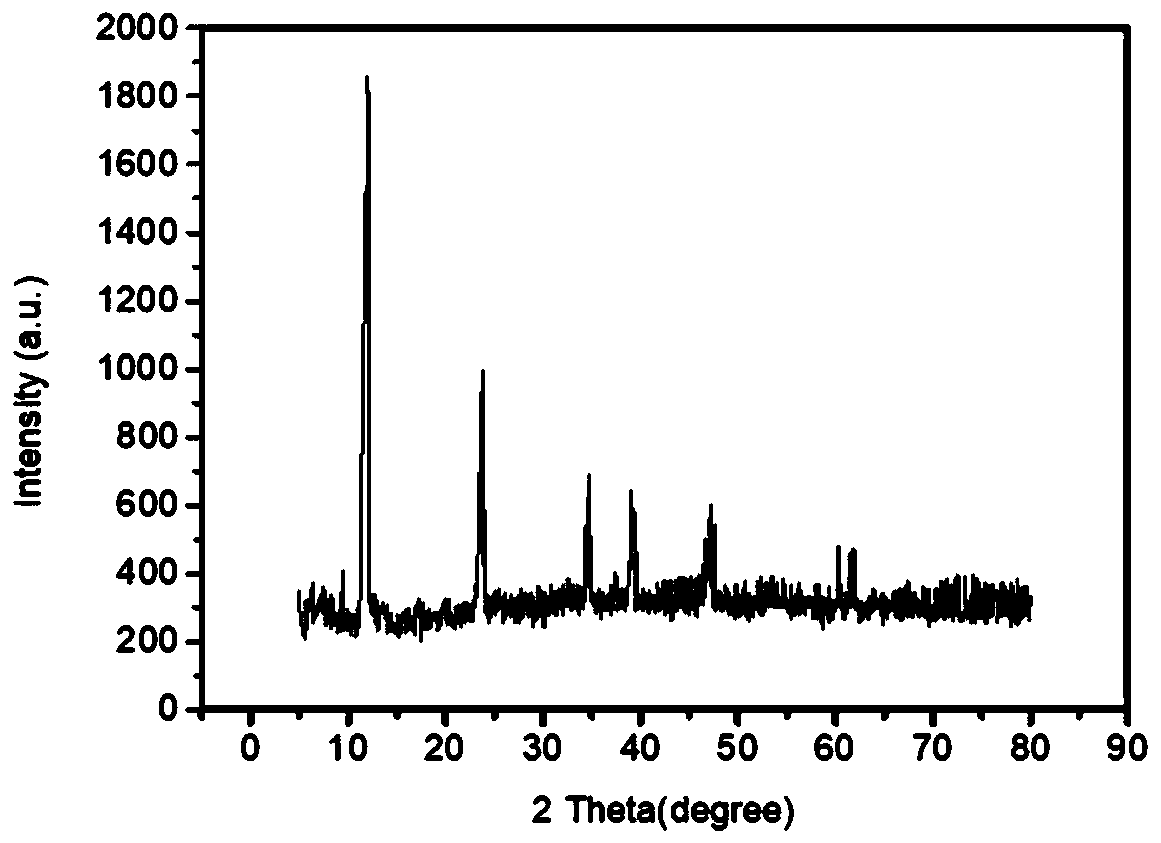

[0029] A preparation method of graphene@CoAl-LDH composite electrode material, obtain graphene oxide aerogel by freeze-drying; prepare CoAl mixed solution; carry out hydrothermal reaction of graphene aerogel and CoAl mixed solution, wait for temperature Cool down to room temperature for freeze-drying to obtain graphene@CoAl-LDH composite electrode material, the specific steps are as follows:

[0030] (1) Preparation of graphene oxide airgel

[0031] Graphene oxide was prepared by the improved Hummer method, the prepared graphene oxide and deionized water were mixed according to the mass ratio of 1:2-3:2 and ultrasonically treated for 1-2h, and then the graphene oxide aqueous solution was frozen Dry for 1-8 hours to obtain graphene oxide airgel.

[0032] (2) Preparation of CoAl mixed solution

[0033] Cobalt salt and deionized water are mixed according to 2mg:1ml-20mg:1ml for 15-30min, aluminum salt and deionized water are mixed according to 2mg:1ml-10mg:1ml for 15-30min, and...

Embodiment 1

[0038] A preparation method of graphene@CoAl-LDH composite electrode material, comprising the steps of:

[0039] (1) Preparation of graphene oxide airgel

[0040] Graphene oxide was prepared by the modified Hummer method, and the prepared graphene oxide and deionized water were treated in a ratio of 1:2, sonicated for 1 h, and freeze-dried for 1 h to obtain the desired graphene oxide aerogel.

[0041] (2) Preparation of CoAl mixed solution

[0042]Prepare the solution of cobalt nitrate and deionized water according to 4mg-1ml, stir for 15min; prepare the solution of aluminum nitrate and deionized water according to 4mg-1ml, stir for 15min; mix the solution of cobalt nitrate and aluminum nitrate according to 5:1, stir for 15min, To obtain a mixed CoAl solution; add cobalt nitrate and urea in a ratio of 1:1; add cobalt nitrate and ammonium fluoride in a ratio of 6:1; add cobalt nitrate and CTAB in a ratio of 4:1; obtain the desired CoAl mixture solution.

[0043] (3) Preparat...

Embodiment 2

[0049] A preparation method of graphene@CoAl-LDH composite electrode material, comprising the steps of:

[0050] (1) Preparation of graphene oxide airgel

[0051] Graphene oxide was prepared by the improved Hummer method, and the prepared graphene oxide and deionized water were treated in a ratio of 1:1, sonicated for 1.5 h, and freeze-dried for 1.5 h to obtain the desired graphene oxide aerogel.

[0052] (2) Preparation of CoAl mixed solution

[0053] Prepare the solution of cobalt nitrate and deionized water according to 10mg-1ml, and stir for 20min; prepare the solution of aluminum nitrate and deionized water according to 10mg-1ml, and stir for 20min; To obtain a mixed CoAl solution; add cobalt nitrate and urea in a ratio of 1:2; add cobalt nitrate and ammonium fluoride in a ratio of 8:1; add cobalt nitrate and CTAB in a ratio of 3:1; obtain the required CoAl mixture solution.

[0054] (3) Preparation of graphene@CoAl-LDH composite electrode material

[0055] The graphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com