Method for improving dispersibility of insoluble amorphous calcium phosphate

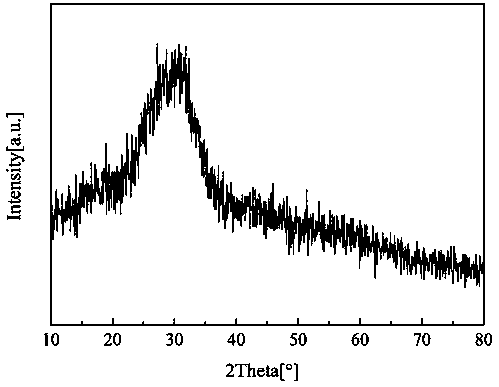

An amorphous calcium phosphate, dispersion technology, applied in the direction of inorganic non-active ingredients, pharmaceutical formulations, active ingredients of ketones, etc., can solve problems such as agglomeration and precipitation, difficult to make pharmaceutical preparations, large specific surface area, etc., to improve Utilization rate, excellent inhibition ability, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example provides a preparation method for improving the dispersibility of insoluble amorphous calcium phosphate, which includes the following steps: firstly prepare ACP nanoparticles by co-precipitation method, then add them into an aqueous solution of sodium hexametaphosphate, and disperse them ultrasonically to form a stable suspension. Specific steps are as follows:

[0027] Prepare 29 mL of calcium nitrate aqueous solution, Ca 2+ The concentration is 0.034 mol / L; prepare 29 mL diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.024 mol / L. According to the molar ratio Ca / P=1.5, the diammonium hydrogen phosphate solution was added dropwise to the calcium nitrate solution under the condition of 30 ºC, and the NaOH solution was adjusted to pH 8. After stirring for 10 min, let it stand for 12 h, and centrifuge. Washing and drying to obtain ACP nanoparticles. Mix the above-mentioned ACP nanoparticles with sodium hexametaphosphate (mass ...

Embodiment 2

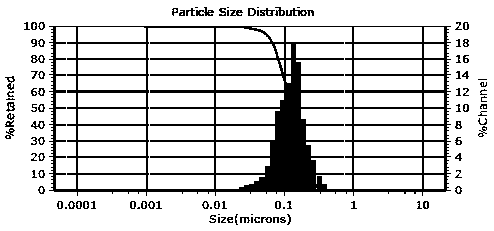

[0030] Prepare 29 mL of calcium nitrate aqueous solution, Ca 2+ The concentration is 0.034 mol / L; prepare 25 mL diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.028 mol / L. According to the molar ratio Ca / P = 1.5, the diammonium hydrogen phosphate solution was added dropwise to the calcium nitrate solution at 25 ºC, and the NaOH solution was adjusted to pH 7. After stirring for 1 h, let it stand for 12 h, and centrifuge. Washing and drying to obtain ACP nanoparticles. The average particle size measured by the laser particle size analyzer is 126 nm (such as figure 2 shown). Mix the above-mentioned ACP nanoparticles with sodium hexametaphosphate (mass ratio is 1:5), add them into water, disperse uniformly with the probe ultrasonic, the ultrasonic power of the probe is 500 W, ultrasonic 3 s, intermittent 2 s, to obtain a stable suspension of nanocomposite particles liquid and dried to obtain nanocomposite particles.

Embodiment 3

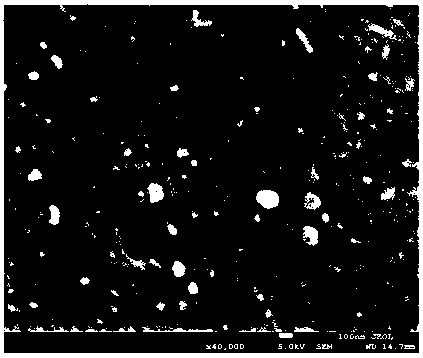

[0032] Prepare 29 mL of calcium nitrate aqueous solution, Ca 2+ The concentration is 0.034 mol / L; prepare 20 mL diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.034 mol / L. According to the molar ratio Ca / P = 1.5, the diammonium hydrogen phosphate solution was added dropwise to the calcium nitrate solution at 40 ºC, and the NaOH solution was adjusted to pH 9. After stirring for 2 hours, let it stand for 12 hours, and centrifuge. Washing and drying to obtain ACP nanoparticles. From the SEM images ( image 3 ), it can be seen that the formed nanocomposite particles are spherical, with a particle size of about 100 nm and uniform particle size. Mix the above-mentioned ACP nanoparticles with sodium hexametaphosphate (mass ratio is 1:3), add them into water, disperse uniformly with the probe ultrasonic, the ultrasonic power of the probe is 300 W, ultrasonic 3 s, intermittent 2 s, to obtain a stable suspension of nanocomposite particles liquid and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com