Calcium-doped ternary positive electrode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as limited applications, and achieve the effects of low cost, readily available raw materials, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the above-mentioned calcium-doped lithium-ion battery ternary positive electrode material proposed by the present invention specifically includes the following steps:

[0017] 1) According to the molar ratio of Li:(Ni+Mn+Co+Ca)=1:1, nickel acetate, manganese acetate, cobalt acetate, calcium nitrate and LiOH·H 2 O grinding and mixing, wherein, Ni 0.8-x mn 0.1 co 0.1 Ca x o 2 , 0≤x≤0.08, to obtain a mixture of acetate, calcium nitrate and lithium hydroxide;

[0018] 2) Put the obtained mixture in a muffle furnace, raise the temperature to 500°C at a heating rate of 3°C-5°C / min, and keep it for 5-8 hours;

[0019] 3) Then raise the temperature to 700-1000°C at a heating rate of 3°C-5°C / min, and calcine for 12-24 hours;

[0020] 4) naturally cooling to room temperature to obtain a calcium-doped lithium ion battery ternary cathode material.

Embodiment 1

[0022] LiNi 0.78 mn 0.1 co 0.1 Ca 0.02 o 2 Preparation of:

[0023] 1) According to the molar ratio of Li:(Ni+Mn+Co+Ca)=1:1, mix 7.84mmol nickel acetate, 1mmol manganese acetate, 1mmol cobalt acetate, 0.16mmol calcium nitrate and 10mmolLiOH·H 2 O grinds and mixes, obtains the mixture of acetate, calcium nitrate and lithium hydroxide;

[0024] 2) Put the obtained mixture in a muffle furnace, raise the temperature to 500°C at a heating rate of 3°C / min, and keep it for 8 hours;

[0025] 3) heating up to 700° C. at the same heating rate, and calcining for 12 hours;

[0026] 4) naturally cooling to room temperature to obtain a calcium-doped lithium ion battery ternary cathode material.

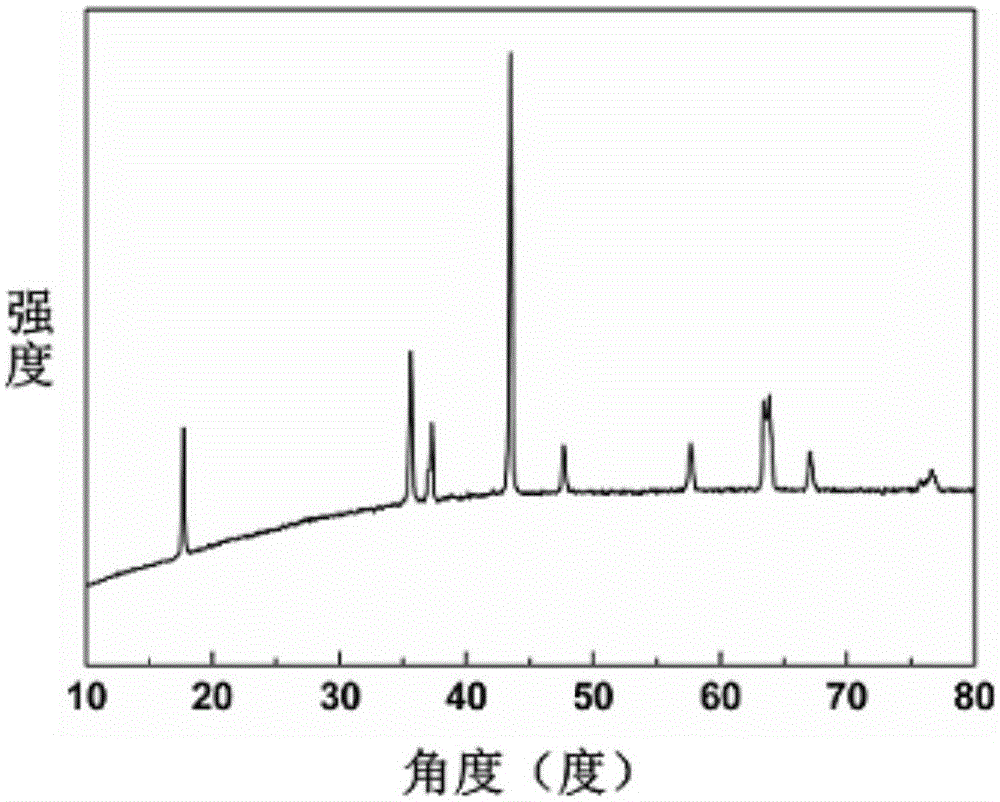

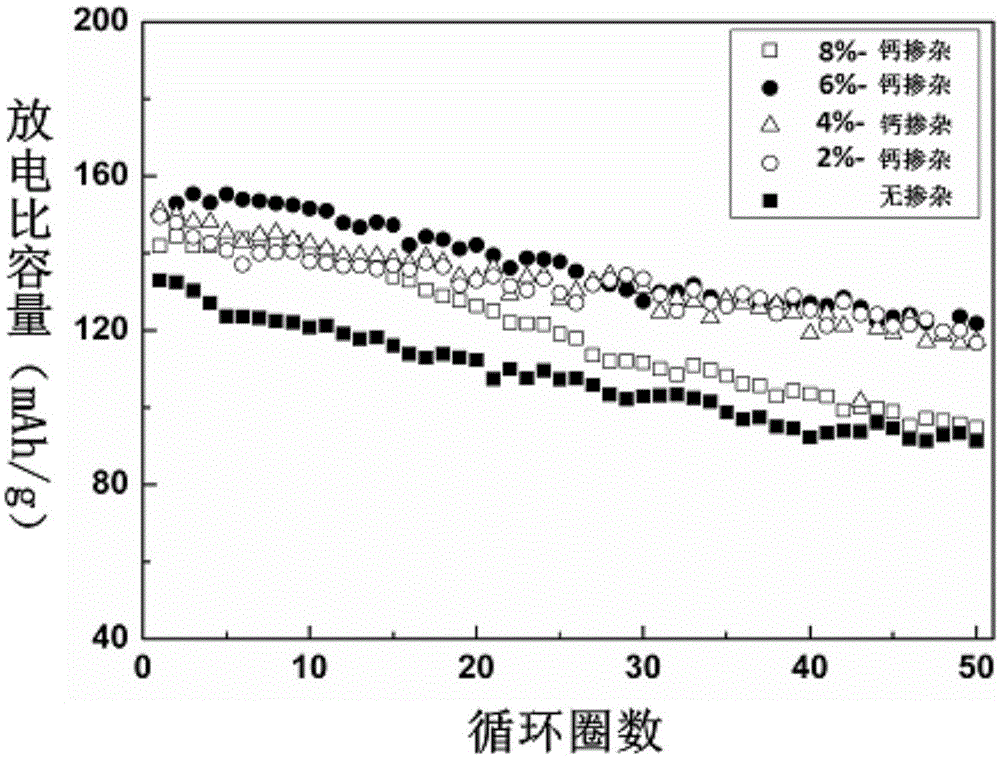

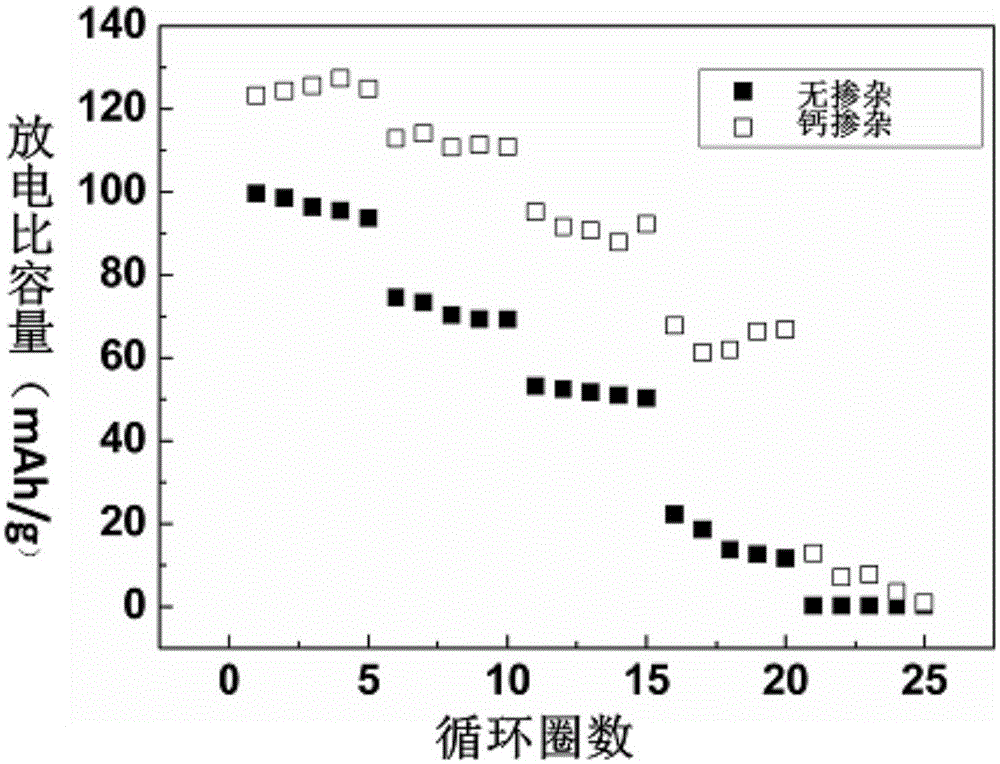

[0027] Characterization of the obtained calcium-doped ternary positive electrode material: the obtained calcium-doped ternary positive electrode material is analyzed by an X-ray diffractometer and can be known as a solid solution of a pure phase, such as figure 1 shown. figure 2 It is the...

Embodiment 2

[0029] LiNi 0.78 mn 0.1 co 0.1 Ca 0.02 o 2 Preparation of:

[0030] 1) According to the molar ratio of Li:(Ni+Mn+Co+Ca)=1:1, mix 7.84mmol nickel acetate, 1mmol manganese acetate, 1mmol cobalt acetate, 0.16mmol calcium nitrate and 10mmolLiOH·H 2 O grinds and mixes, obtains the mixture of acetate, calcium nitrate and lithium hydroxide;

[0031] 2) Put the obtained mixture in a muffle furnace, raise the temperature to 500° C. at a heating rate of 4° C. / min, and keep it for 5 hours;

[0032] 3) heating up to 800° C. at the same heating rate, and calcining for 12 hours;

[0033] 4) naturally cooling to room temperature to obtain a calcium-doped lithium ion battery ternary cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com