Preparation method of cobaltosic oxide/graphene three-dimensional mixed structure flexible electrode

A three-dimensional mixing technology of cobalt tetroxide, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as poor cycle stability of cobalt tetroxide, inability to develop specific surface area, and easy stacking of graphene, so as to avoid cycle stability Poor, improve cycle stability, improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

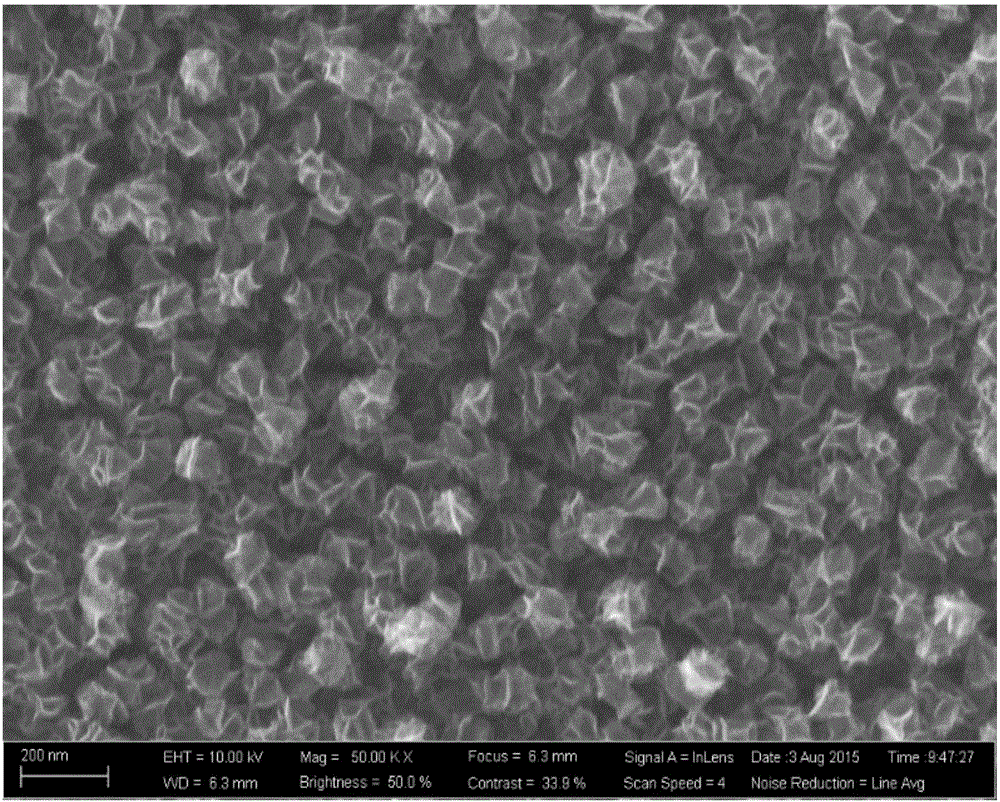

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment 1: The preparation method of a kind of three-dimensional cobalt tetroxide / graphene mixed structure flexible electrode described in this embodiment is specifically carried out according to the following steps:

[0020] 1. Under the condition of rotating speed of 3000 rpm to 5000 rpm, centrifuge the graphene oxide solution for 2 min to 10 min, then ultrasonically treat it for 10 min to 30 min, filter impurities, and obtain a pretreated graphene oxide solution;

[0021] The concentration of the graphene oxide solution is 0.1mg / mL~1mg / mL;

[0022] 3. ①. At room temperature, place nickel foam in the pretreated graphene oxide solution to react for 1min to 5min, and then dry it in a vacuum oven at a temperature of 50°C to 100°C for 3min to 10min to obtain the reacted material ; ②, at room temperature, place the reacted material in the pretreated graphene oxide solution for 1min to 5min, and then dry it in a vacuum oven at a temperature of 50°C to 100°C for ...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that: the nickel foam described in Step 2 ① is ultrasonically cleaned with dilute hydrochloric acid for 5 minutes, acetone for 5 minutes and deionized water for 5 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step three, the sealed reaction kettle is placed in an oven with a temperature of 75°C to 210°C for 2h to 7h to obtain foamed nickel Material. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com