Method for preparing nanometer trinickel nitride powder

A nano-nickel nitride technology, which is applied in the field of preparing nano-nickel nitride powder, can solve the problems of harsh reaction conditions, high raw material costs, and low product purity, and achieve good stability, simple preparation methods, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Grind and mix 1.4543g (0.005mol) nickel nitrate hexahydrate and 2.5224g (0.020mol) melamine evenly, wherein the molar ratio of nickel element to melamine is 1:4, roast at 480°C for 3 hours in a nitrogen atmosphere, cool to room temperature, Nano-nickel nitride powder is obtained.

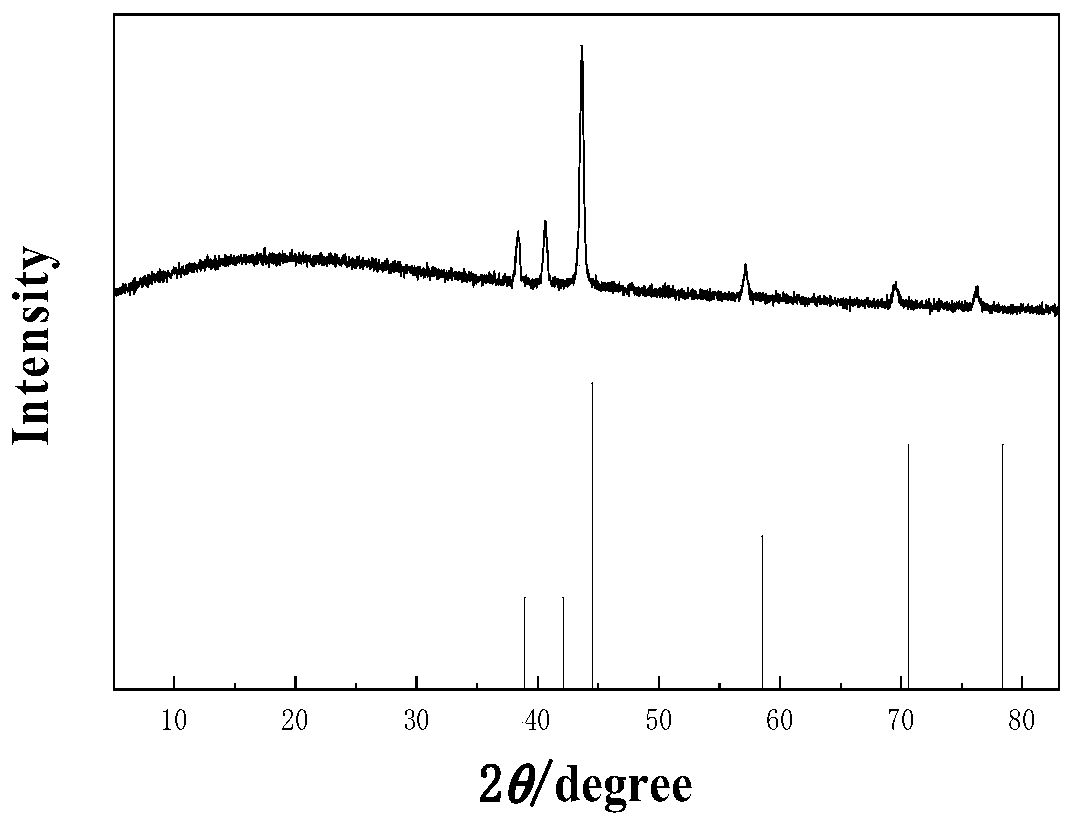

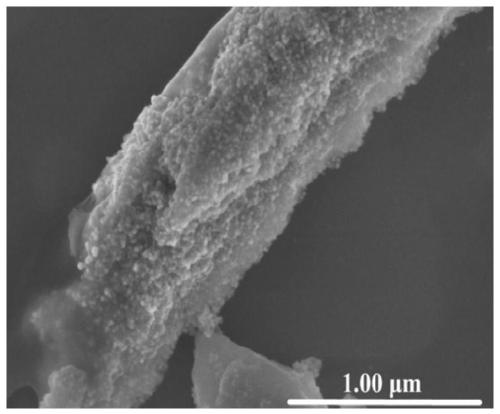

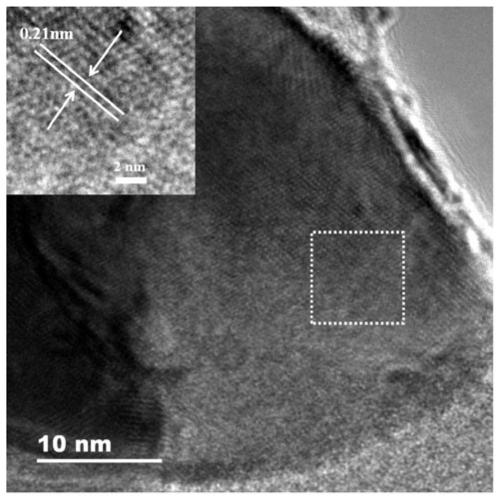

[0040] Depend on figure 1 Visible, the XRD diffraction peak of obtained sample and standard Ni 3 The N diffraction peaks are completely consistent without any other peaks, indicating that the prepared Ni3N3 has a high purity. At the diffraction peak position with a 2θ value of 44°, the Ni3Ni crystal size calculated by the Scherrer formula is 15.7nm, which is the average value of crystal grains in the vertical direction of 44° (111 crystal plane). Depend on figure 2 and image 3 It can be seen that the prepared nickel-nitride particles are small and evenly distributed, and the interplanar spacing of nickel-nitride can be obtained from the (110) crystal plane is 0.21 nm.

Embodiment 2

[0042] Grind and mix 1.4543g (0.005mol) nickel nitrate hexahydrate and 2.5224g (0.020mol) melamine evenly, wherein the molar ratio of nickel element to melamine is 1:4, roast at 500°C for 3 hours in a nitrogen atmosphere, cool to room temperature, Obtain nano-nickel nitride powder (see Figure 4 ). The crystal size of Ni3Ni3 was calculated by Scherrer's formula at the diffraction peak position with 2θ value of 44° as 22.4nm.

Embodiment 3

[0044] Grind and mix 1.4543g (0.005mol) nickel nitrate hexahydrate and 1.8918g (0.015mol) melamine evenly, wherein the molar ratio of nickel element to melamine is 1:3, bake at 480°C for 3 hours in an argon atmosphere, and cool to room temperature , to obtain nano-nickel nitride powder (see Figure 5 ). The crystal size of Ni3Ni3 was calculated using Scherrer's formula at the position of the diffraction peak with a 2θ value of 44° to be 23.1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com