Flower type Ni<3>S<2>/graphene three-dimensional composite electrode material and preparation method thereof

A technology of three-dimensional composite and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of graphene easy to agglomerate and stack, easy to agglomerate and lack of conductivity, and achieve easy control of the reaction process , high specific surface area, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

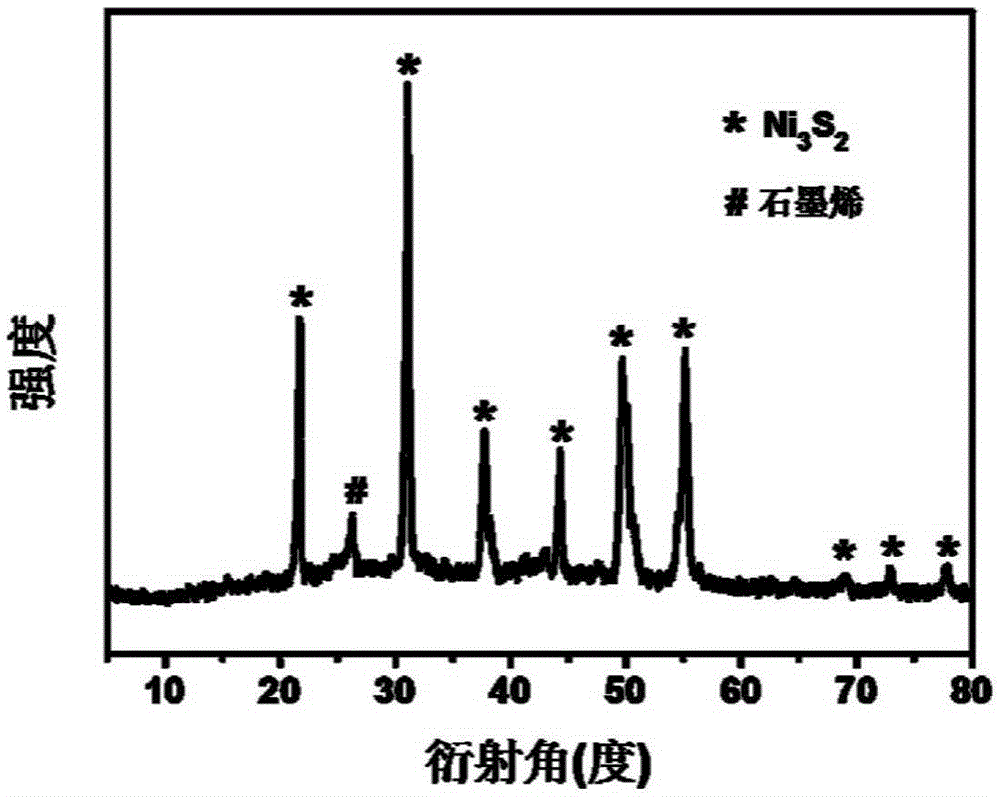

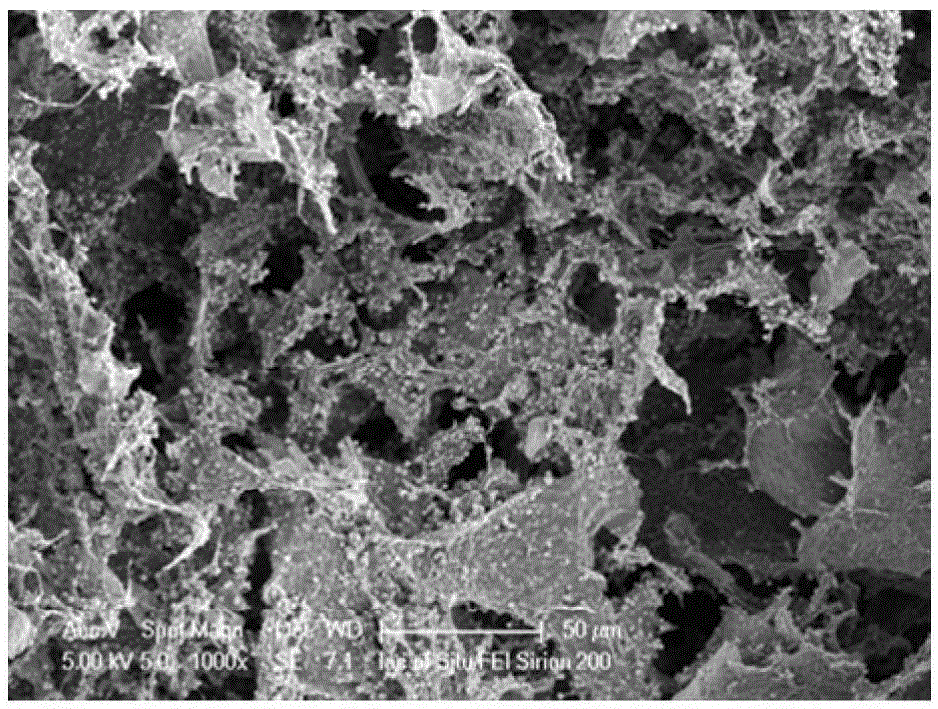

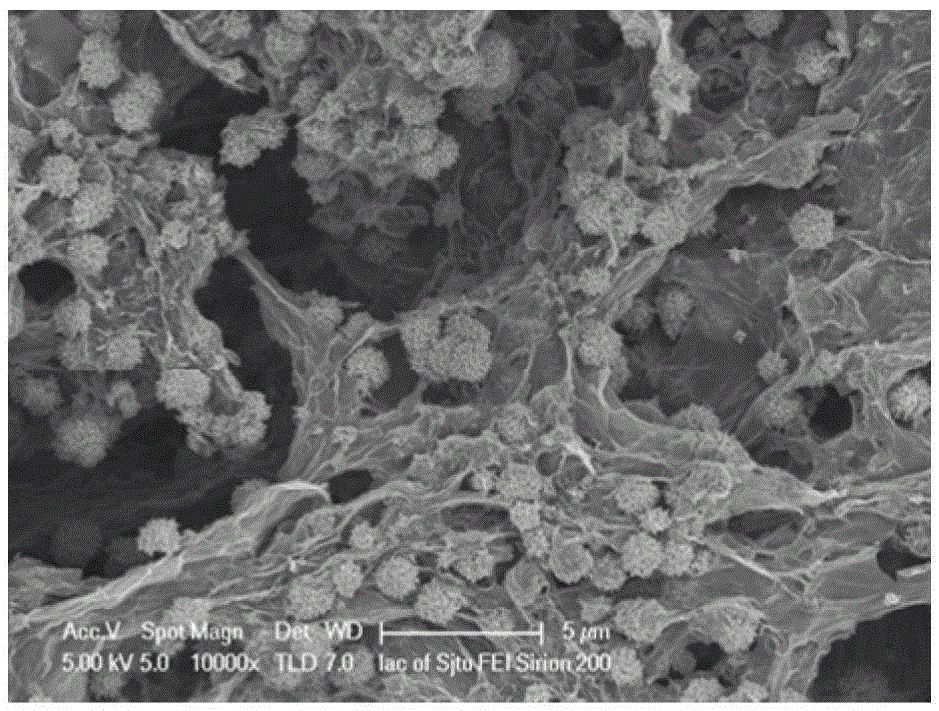

[0039] A flower type of Ni 3 S 2 / Graphene three-dimensional composite electrode material, based on graphene, uniformly grows flower-shaped Ni on the surface of graphene 3 S 2 particles.

[0040] Above-mentioned a kind of supercapacitor uses the Ni of pattern 3 S 2 The preparation method of / graphene three-dimensional composite electrode material specifically comprises the following steps:

[0041] (1) Control the power of graphene oxide, thiourea, nickel acetate tetrahydrate and triblock polymer F127 at 300-400W and ultrasonically disperse them in distilled water under ultrasonic conditions at room temperature to obtain a mixed solution;

[0042] In the above mixed solution, calculated per liter, its components and contents are as follows:

[0043] Graphene oxide 1g,

[0044] Thiourea 5g,

[0045] Nickel acetate tetrahydrate 15.5g,

[0046] Triblock polymer F1270.08g,

[0047] The balance is distilled water;

[0048] (2) Transfer the mixed solution obtained in step ...

Embodiment 2

[0059] A flower type of Ni 3 S 2 / Graphene three-dimensional composite electrode material, based on graphene, uniformly grows flower-shaped Ni on the surface of graphene 3 S 2 particles.

[0060] One of the above flower patterns of Ni 3 S 2 The preparation method of / graphene three-dimensional composite electrode material specifically comprises the following steps:

[0061] (1) Control the power of graphene oxide, thiourea, nickel acetate tetrahydrate and triblock polymer F127 at 300-400W and ultrasonically disperse them in distilled water under ultrasonic conditions at room temperature to obtain a mixed solution;

[0062] In the above mixed solution, calculated per liter, its components and contents are as follows:

[0063] Graphene oxide 1g,

[0064] Thiourea 2g,

[0065] Nickel acetate tetrahydrate 6.5g,

[0066] Triblock polymer F1270.04g,

[0067] The balance is distilled water;

[0068] (2) Transfer the mixed solution obtained in step (1) into a hydrothermal ke...

Embodiment 3

[0074] A flower type of Ni 3 S 2 / Graphene three-dimensional composite electrode material, based on graphene, uniformly grows flower-shaped Ni on the surface of graphene 3 S 2 particles.

[0075] One of the above flower patterns of Ni 3 S 2 The preparation method of / graphene three-dimensional composite electrode material specifically comprises the following steps:

[0076] (1) Control the power of graphene oxide, thiourea, nickel acetate tetrahydrate and triblock polymer F127 at 300-400W and ultrasonically disperse them in distilled water under ultrasonic conditions at room temperature to obtain a mixed solution;

[0077] In the above mixed solution, calculated per liter, its components and contents are as follows:

[0078] Graphene oxide 1g,

[0079] Thiourea 4g,

[0080] Nickel acetate tetrahydrate 12.4g,

[0081] Triblock polymer F1270.06g,

[0082] The balance is distilled water;

[0083] (2) Transfer the mixed solution obtained in step (1) into a hydrothermal k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com