Method for preparing parallel polycrystalline nano fiber bundle of stannic oxide and nickel oxide

A nanofiber, tin dioxide technology, used in fiber processing, spinning solution preparation, fiber chemical characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

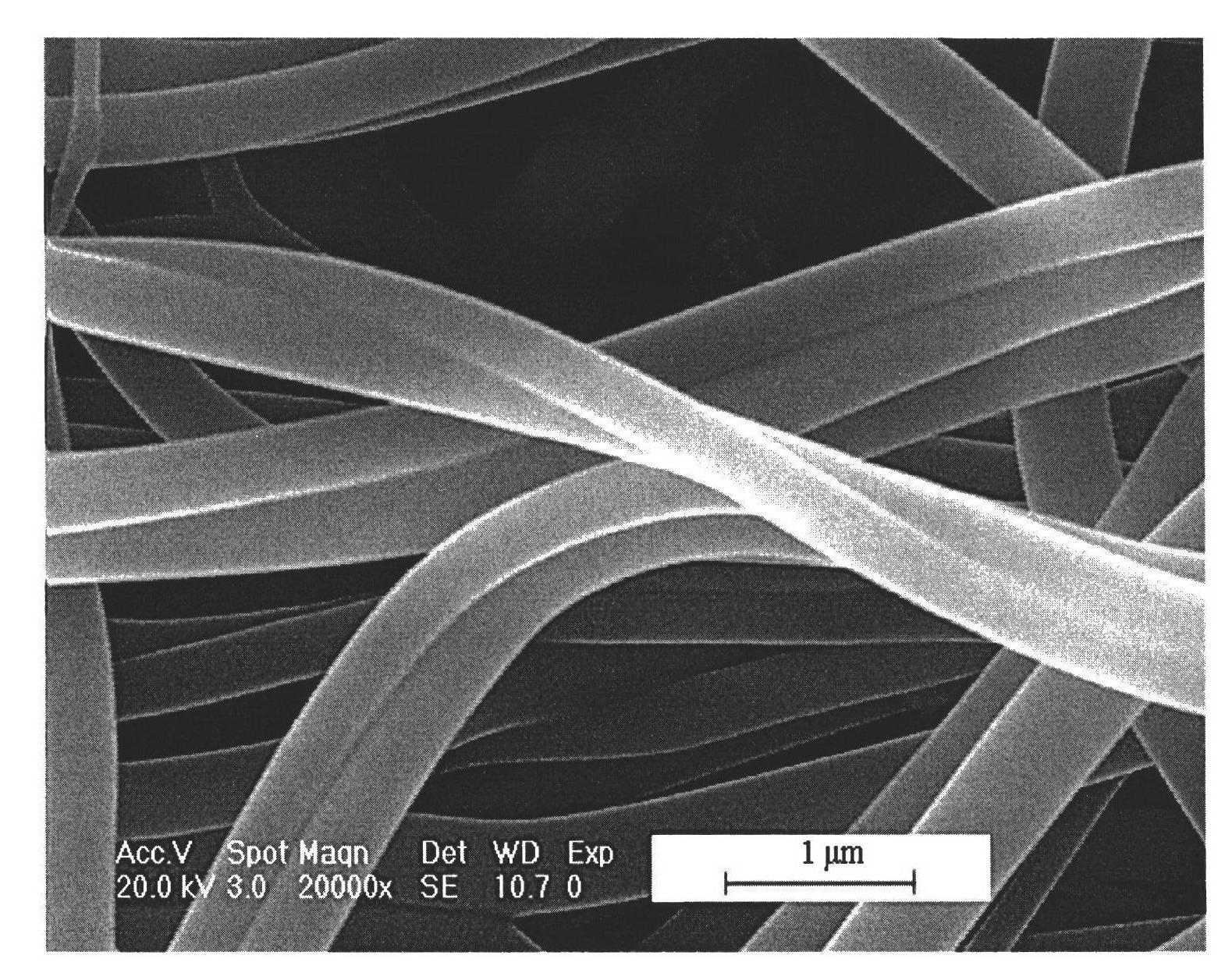

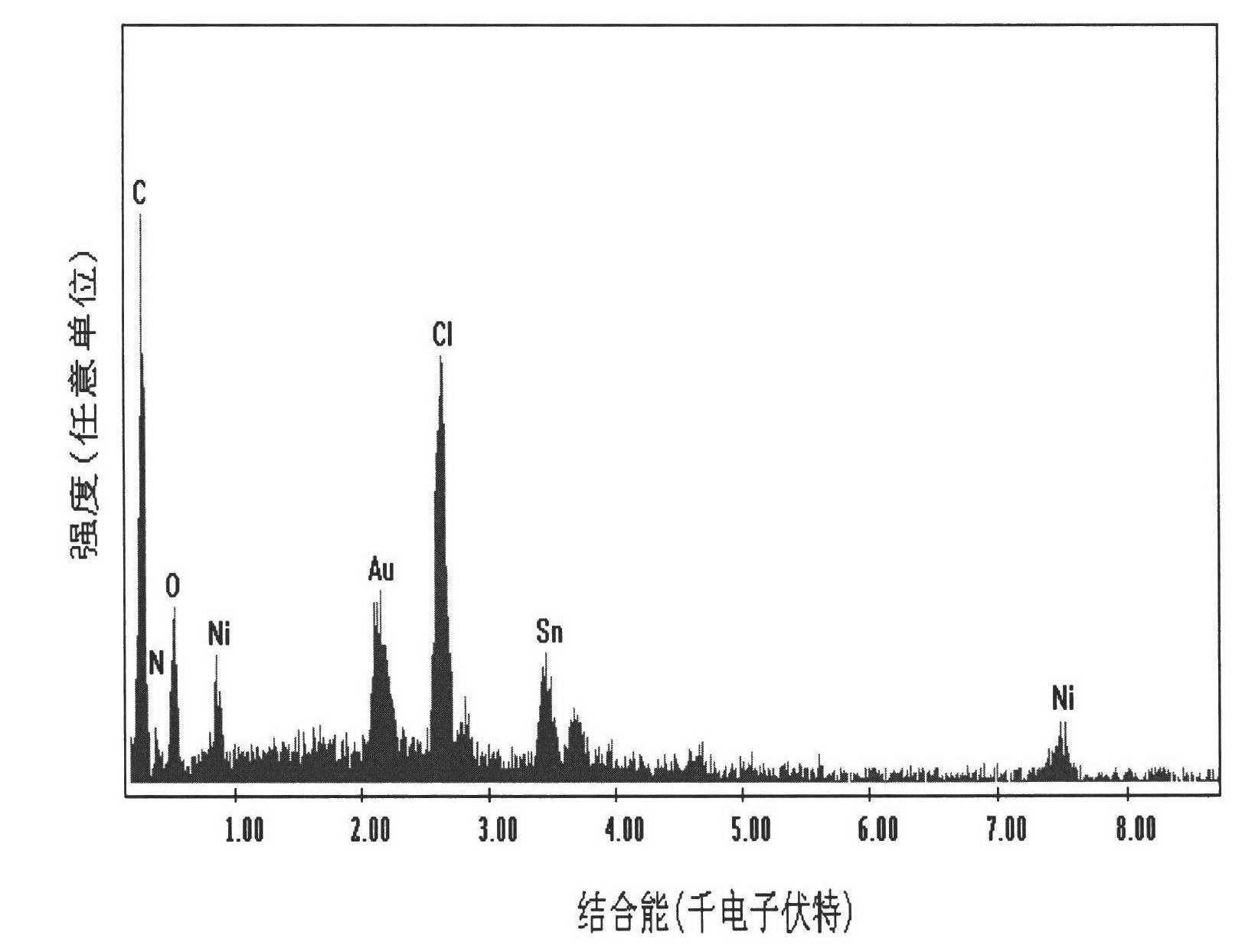

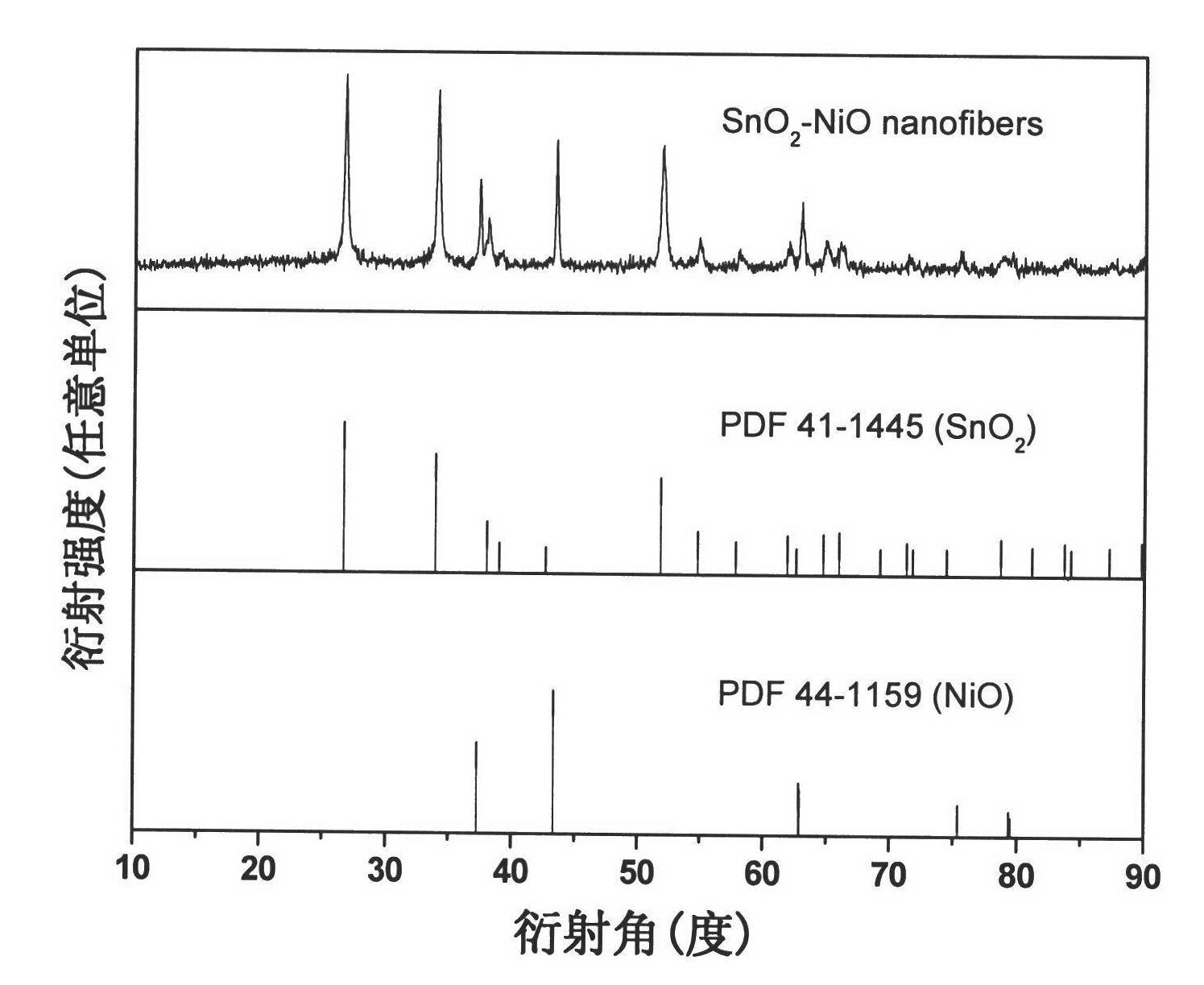

[0019] Embodiment: tin tetrachloride pentahydrate SnCl 4 ·5H 2 O and polyvinylpyrrolidone PVP, with a molecular weight of 90000, were added to N, N-dimethylformamide DMF, stirred magnetically for 8 hours at room temperature, and left to stand for 2 hours to form a spinning solution. The mass of each substance in the spinning solution The percentage is: SnCl 4 ·5H 2 O is 10%, PVP is 15.2%, and DMF is 74.8%; nickel acetate tetrahydrate Ni(CH 3 COO) 2 4H 2 O and PVP are added in DMF, magnetically stirred at room temperature for 8h, and left to stand for 2h to form another spinning solution. The mass percentage of each substance in the spinning solution is: Ni(CH 3 COO) 2 4H 2 O is 10%, PVP is 15.2%, and DMF is 74.8%. Electrospinning technology is used for spinning. The spinneret is composed of two truncated syringe needles with the same diameter. The two needles are 5# stainless steel needles with an outer diameter of 0.5mm, the inner diameter is 0.232mm, the two prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com