Method of preparing titanium dioxide, stannum dioxide and doping composite fiber material thereof

A composite fiber and tin dioxide technology, applied in the field of nanomaterials, to achieve the effects of cost reduction, raw material saving, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 The preparation of titanium dioxide fiber

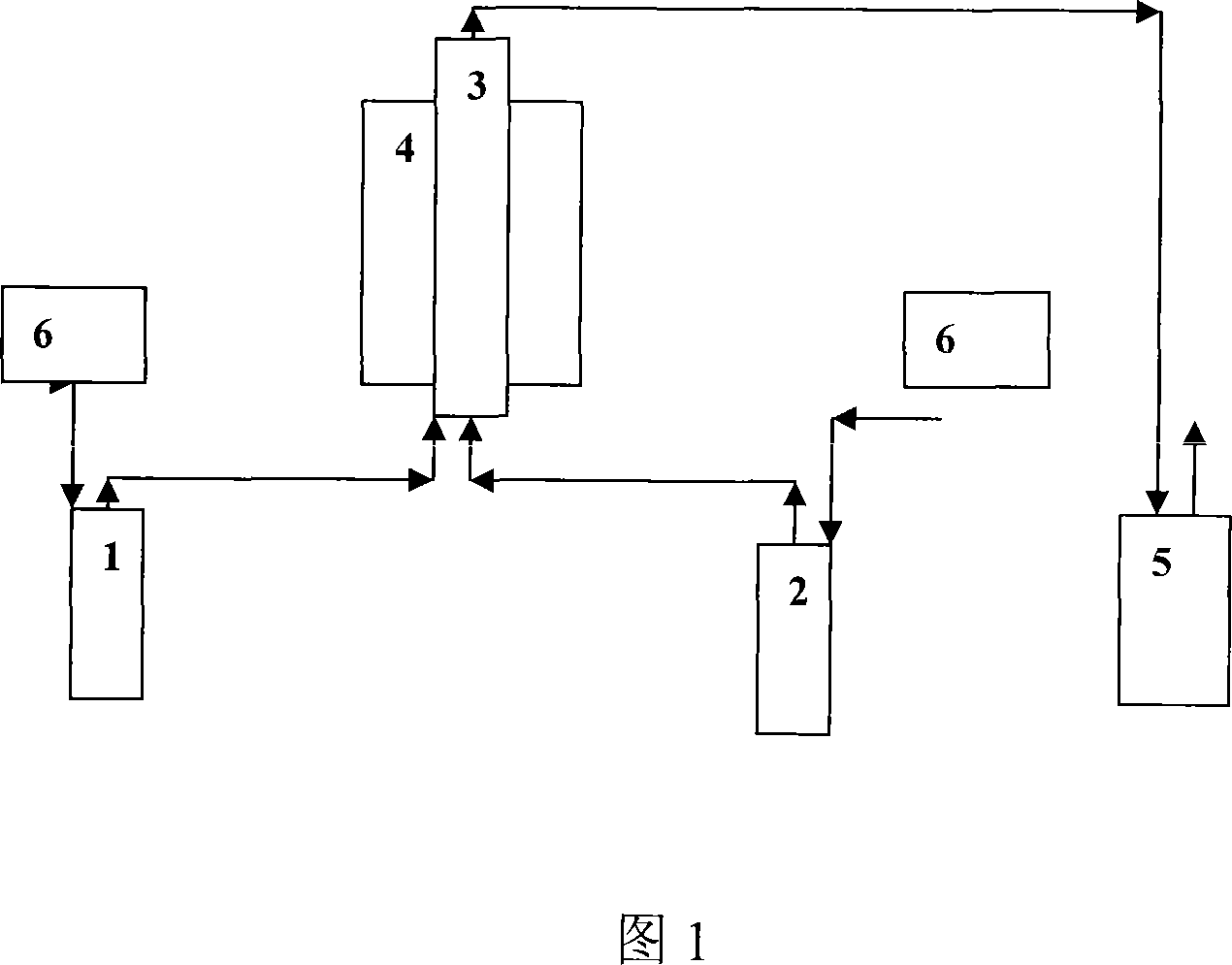

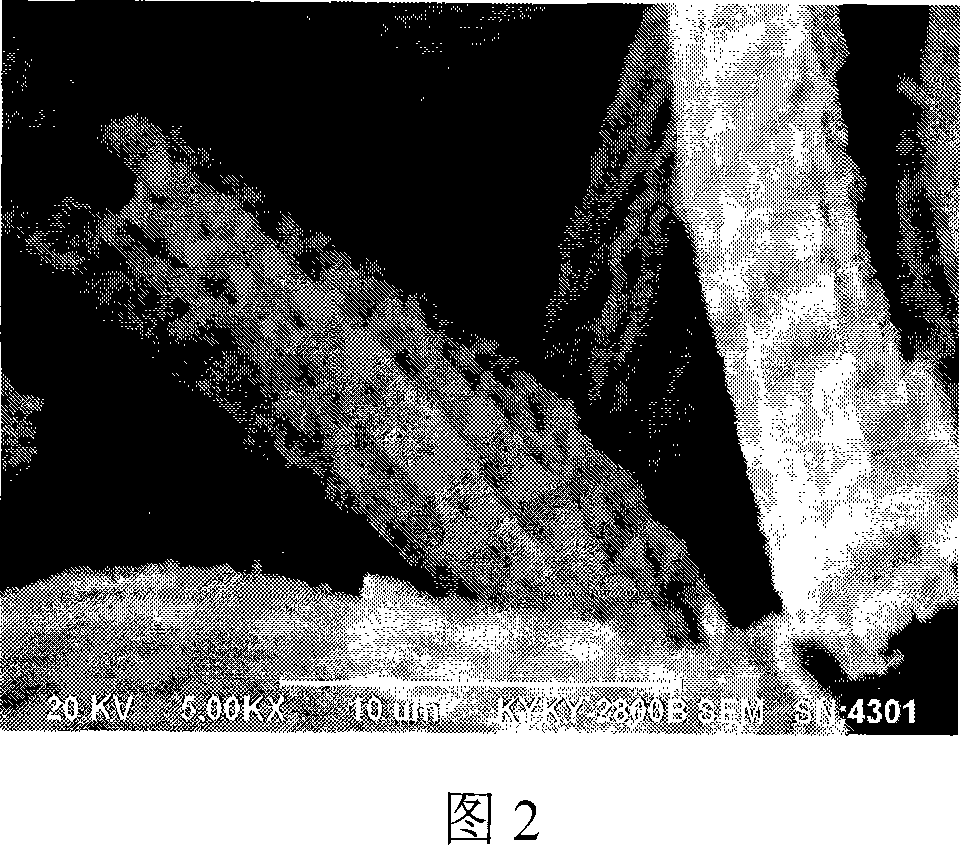

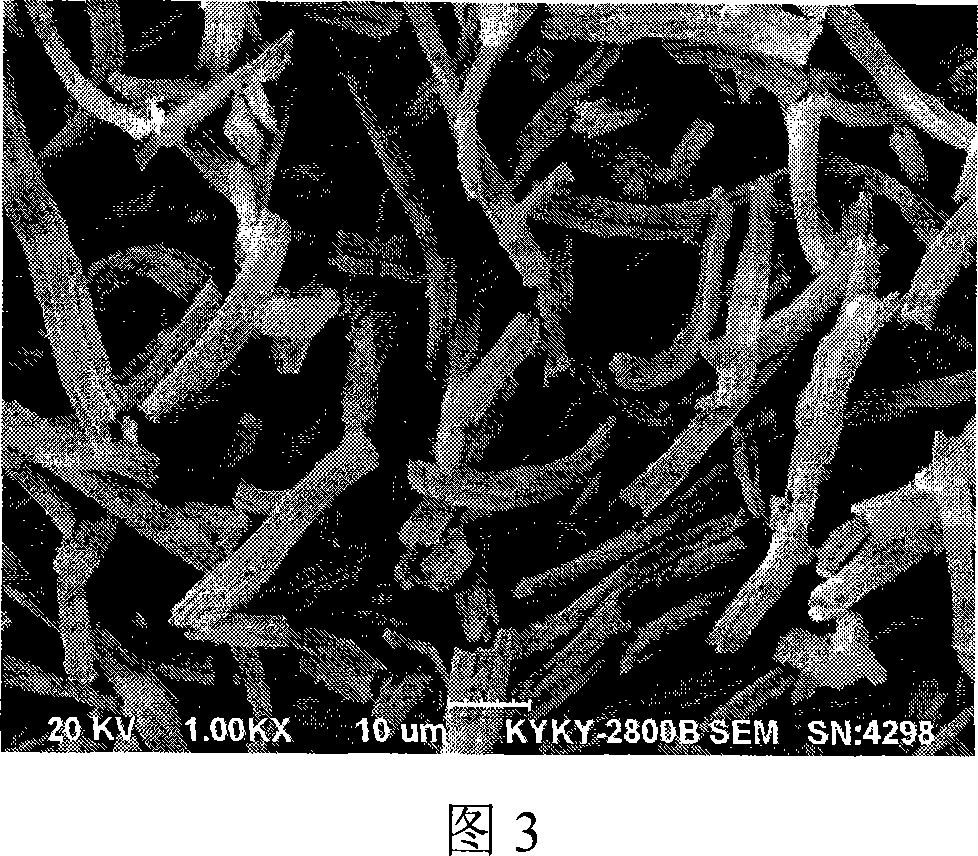

[0042] Deposition on the surface of activated carbon fibers: put activated carbon fibers into the reactor in the schematic diagram of the fiber material preparation device shown in Figure 1, pass nitrogen to carry titanium tetrachloride vapor and ammonia solution at a predetermined temperature of 5 to 70 ° C, and use a certain The line velocity is 0.01-120cm / min into the reactor, and the temperature of the reactor is maintained at 5-280°C. The reaction deposition time ranges from 1 to 180 minutes. Afterwards, heat up to 100-900°C in the air for 0.1-6 hours, remove the template, and obtain a fiber material with an irregular pore structure in the middle with the characteristics of nano-anatase or rutile ore structure as shown in Figures 2 and 3. The analysis shows that the titanium dioxide grains are nanoscale, and its fibers have the characteristics of one-dimensional tubes of nanomaterials and three-dimensional s...

Embodiment 2

[0043] Embodiment 2 Preparation of composite tin dioxide and titanium dioxide fibers

[0044] Put the activated carbon fiber into the reactor, feed the precursor gas components of tin tetrachloride and titanium in proportion, and alternately feed the water gas component at the same time, enter the reactor to cause the hydrolysis reaction of the precursor, and deposit in the pores of the activated carbon fiber Structure and surface. The temperature range of the reactor is 5-280°C, the temperature of the precursor is 5-70°C, the linear flow rate is in the range of 0.01-120cm / min, sintering in the air, the temperature is 100-900°C and the time range is 1-6 hours, and different Proportional titanium dioxide tin dioxide composite (tubular) fibers.

Embodiment 3

[0045] The preparation of embodiment 3 tin dioxide fibers:

[0046] Carbon fiber surface deposition: Put activated carbon fibers into the reactor of the fiber material preparation device shown in Figure 1, pass nitrogen gas to carry tin tetrachloride vapor and ammonia solution at a predetermined temperature of 5-70 ° C, and use a certain linear speed of 0.01 ~ 120cm / min enters the reactor, and the temperature of the reactor is maintained at 5-280°C. The reaction deposition time ranges from 1 to 180 minutes. Then heat up to 100-900° C. in air for 0.1-6 hours, remove the template, and obtain a tin dioxide fiber material with an irregular pore structure in the middle. If the sintering is performed under a nitrogen atmosphere or an inert gas atmosphere, the template is not removed, and the tin dioxide of the composite carbon fiber is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com