Method for preparing graphene aerogel loaded tin dioxide composite material

A graphene aerogel, tin dioxide technology, applied in tin oxide, nanotechnology for materials and surface science, electrical components, etc., can solve the problems of reducing material capacity, particle pulverization and agglomeration, poor conductivity, etc. , to achieve the effect of simple preparation process, excellent electrical conductivity, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

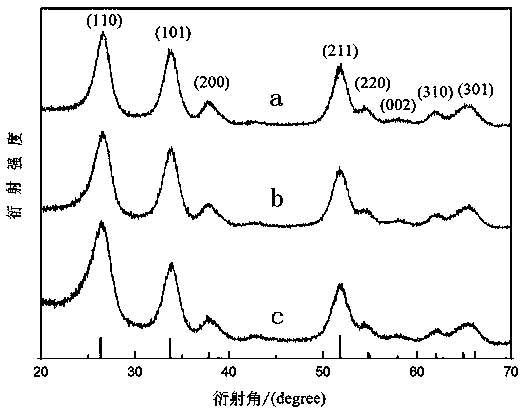

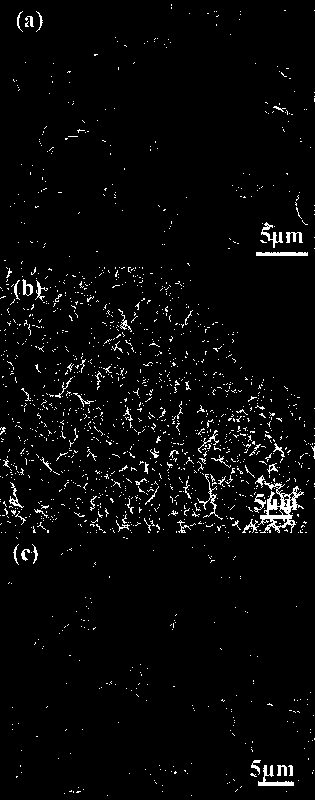

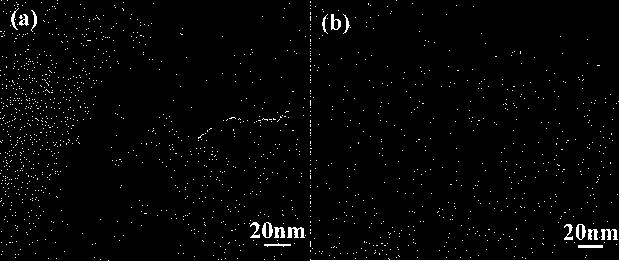

Examples

Embodiment 1

[0030] Graphene oxide used in the present invention is to adopt traditional known process method to make, and its preparation method is as follows:

[0031] Potassium persulfate (K 2 S 2 o 8 ) 2.5 g, phosphorus pentoxide (P 2 o 5 ) 2.5 g, dissolved in 12 mL of concentrated sulfuric acid, heated to 80°C; then 3 g of natural graphite was added to the above solution, kept at 80°C for 4.5 hours; cooled to room temperature, diluted with 500 mL of deionized water, and left standing overnight ; filter, float residual acid with 0.2 mm filter; dry in a vacuum oven at 60°C; add the obtained preoxide to 120 mL of ice-bathed concentrated sulfuric acid, slowly add 15 g of KMnO under stirring 4 , Keep the temperature below 20°C during the addition process. Then the temperature was controlled at 35°C and stirred for 2 h. Add 250 mL of deionized water to dilute, and keep the temperature below 50°C in an ice bath during the dilution process. Stir for another 2 h, add 0.7 L of deionized ...

Embodiment 2

[0041] The preparation method of graphene oxide is the same as embodiment 1.

[0042] Preparation of graphene airgel-supported tin dioxide composites:

[0043] 1. Take 30 mL of graphene oxide solution (3 mg / mL) into a beaker, add 20 mL of deionized water and stir for 20 min to mix well, then sonicate for 1 h.

[0044] 2. Weigh 150 mg of tin tetrachloride and dissolve in 10 mL of deionized water, stir magnetically for 5 min, pour into the graphene oxide solution in step 1, stir magnetically for 2 h, and sonicate for 1 h.

[0045] 3. Measure 0.5 mL of 1-propylamine and pour it into the mixed solution in step 2, and stir magnetically for 1 h.

[0046] 4. Transfer the mixed solution into a hydrothermal reaction kettle and keep it at 180°C for 12 hours. After the reaction kettle drops to room temperature, take out the cylindrical product and wash it with alcohol and water for three times; The graphene airgel-supported tin dioxide composite material was obtained by freeze-drying o...

Embodiment 3

[0050] The preparation method of graphene oxide is the same as embodiment 1.

[0051] Preparation of graphene airgel-supported tin dioxide composites:

[0052] 1. Take 40 mL of graphene oxide solution (3 mg / mL) into a beaker, add 10 mL of deionized water and stir for 20 min to mix evenly, then sonicate for 2 h.

[0053] 2. Weigh 200 mg of stannous chloride and dissolve in 10 mL of deionized water, stir magnetically for 5 min, pour into the graphene oxide solution in step 1, stir magnetically for 1 h, and sonicate for 1 h.

[0054] 3. Measure 1 mL of urea and pour it into the mixed solution in step 2, and stir magnetically for 1 hour.

[0055] 4. Transfer the mixed solution into the reaction kettle and keep it at 120°C for 8 hours. After the reaction kettle drops to room temperature, take out the cylindrical product and wash it with alcohol and water three times; put the obtained cylindrical product into a freeze dryer at -52°C Freeze-dry overnight to obtain the graphene ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com