Two-dimensional oversized mint-leaf-shaped nickel oxide nano material and preparation method thereof

A technology of nanomaterials and mint leaves, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problem of small size of two-dimensional nickel oxide nanostructures, and achieve the effect of low cost, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The two-dimensional super-large mint leaf-shaped nickel oxide nano material of the present invention is prepared by a two-step method of hydrothermal synthesis and thermal decomposition, and the specific process flow is as follows:

[0026] (1) Weigh 0.5mmol Ni(CH 3 COO) 2 ·4H 2 O and 5mmol urea CO (NH 2 ) 2 , Add to a 100mL beaker, add 60mL of deionized water, stir to dissolve, and obtain a light green solution;

[0027] (2) Transfer the above solution to a 100mL stainless steel reactor with a polytetrafluoroethylene lining, seal it and place it in an oven, set the temperature to 120°C, and react for 12 hours;

[0028] (3) After the reaction, cool to room temperature naturally, filter the precipitate, wash with absolute ethanol and distilled water for 3 to 5 times, and dry the precipitate in a vacuum drying oven for 6 to 8 hours at a temperature of 60°C;

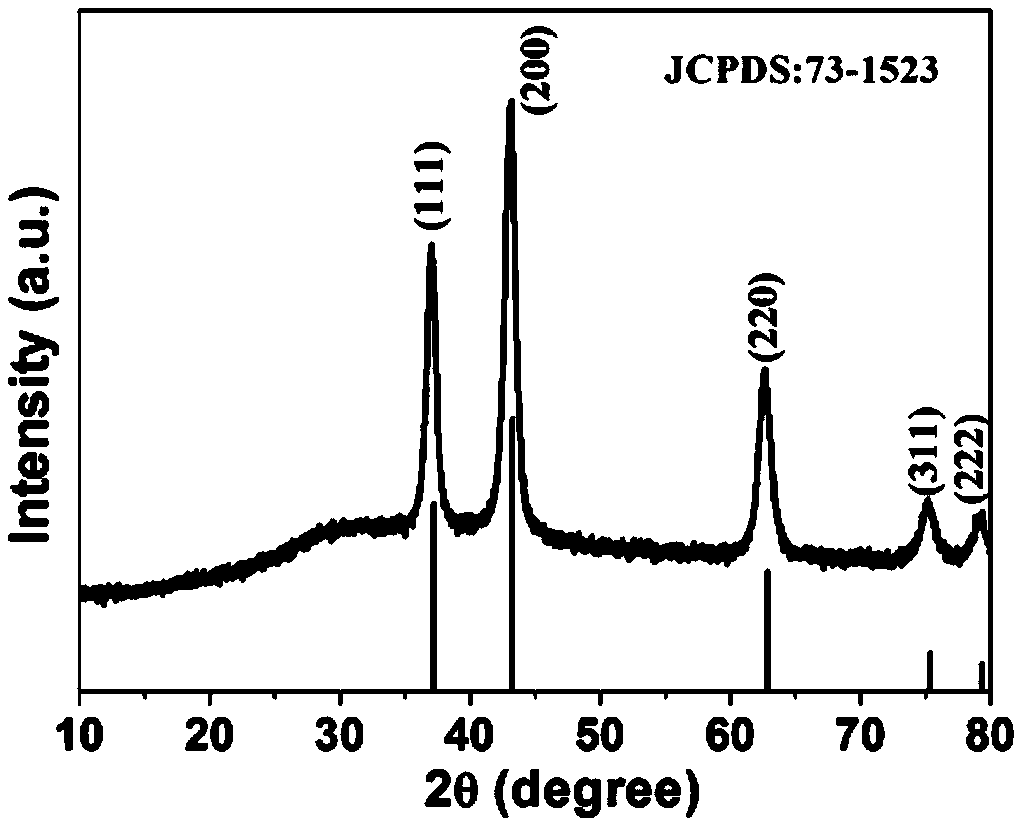

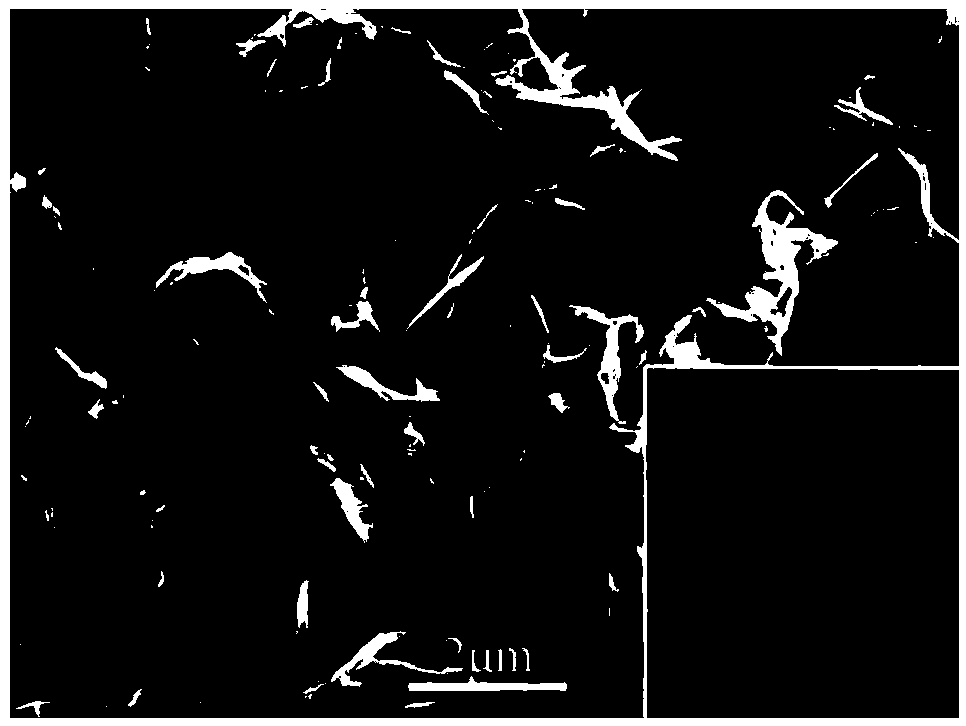

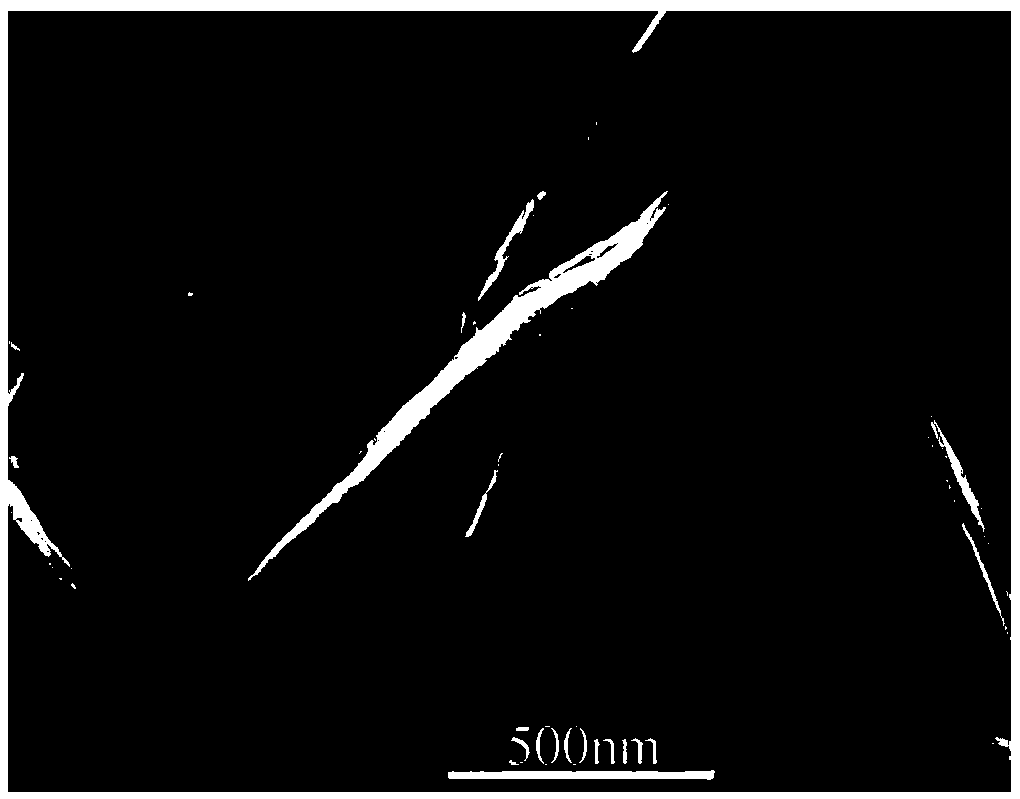

[0029] (4) Put the dried green precipitate in a resistance furnace and heat it at 350°C for 3 hours to obtain a two-dimensi...

Embodiment 2

[0034] The two-dimensional super-large mint leaf-shaped nickel oxide nano material of the present invention is prepared by a two-step method of hydrothermal synthesis and thermal decomposition, and the specific process flow is as follows:

[0035] (1) Weigh 0.5mmol Ni(CH 3 COO) 2 ·4H 2 O and 4mmol urea CO(NH 2 ) 2 , Add it to a 100mL beaker, add 60ml of deionized water, stir to dissolve to obtain a light green solution;

[0036] (2) Transfer the above solution to a 100mL stainless steel reactor with polytetrafluoroethylene lining, place it in an oven after sealing, set the temperature to 130°C, and react for 13 hours;

[0037] (3) After the reaction, cool to room temperature naturally, filter the precipitate, wash with absolute ethanol and distilled water for 3 to 5 times, and dry the precipitate in a vacuum drying oven for 6 to 8 hours at a temperature of 50°C;

[0038] (4) Put the dried green precipitate in a resistance furnace and heat it at 400°C for 2 hours to obtain a two-dimensi...

Embodiment 3

[0041] The two-dimensional super-large mint leaf-shaped nickel oxide nano material of the present invention is prepared by a two-step method of hydrothermal synthesis and thermal decomposition, and the specific process flow is as follows:

[0042] (1) Weigh 0.5mmol Ni(CH 3 COO) 2 ·4H 2 O and 6mmol urea CO (NH 2 ) 2 , Add it to a 100mL beaker, add 60ml of deionized water, stir to dissolve to obtain a light green solution;

[0043] (2) Transfer the above solution to a 100mL stainless steel reactor with a polytetrafluoroethylene lining, seal it and place it in an oven, set the temperature to 110°C, and react for 14 hours;

[0044] (3) After the reaction, cool to room temperature naturally, filter the precipitate, wash with absolute ethanol and distilled water for 3 to 5 times, and dry the precipitate in a vacuum drying oven for 6 to 8 hours at a temperature of 60°C;

[0045] (4) Put the dried green precipitate in a resistance furnace and heat treatment at 350°C for 4 hours to obtain a two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com