Preparation method of nickel sulfide/graphene/polyaniline composite electrode material

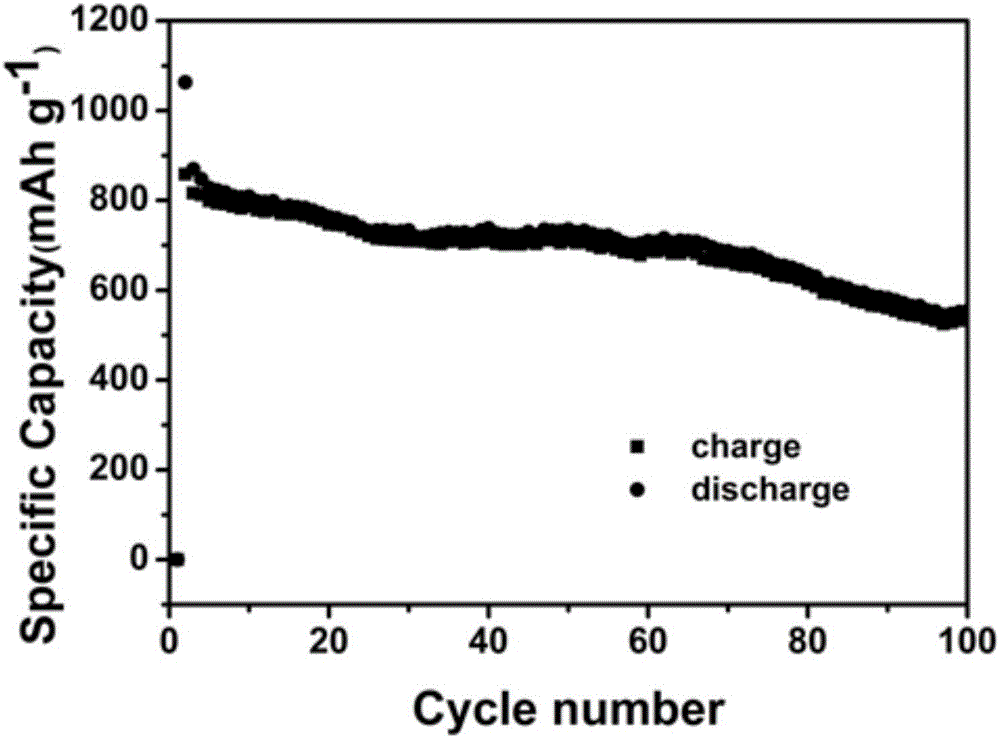

A composite electrode and graphene technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of limited high-power field applications, unsuitable for fast charging and discharging, and low charging and discharging efficiency, so as to improve specific capacity and rate performance , Solve the effects of poor stability, low rate performance and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

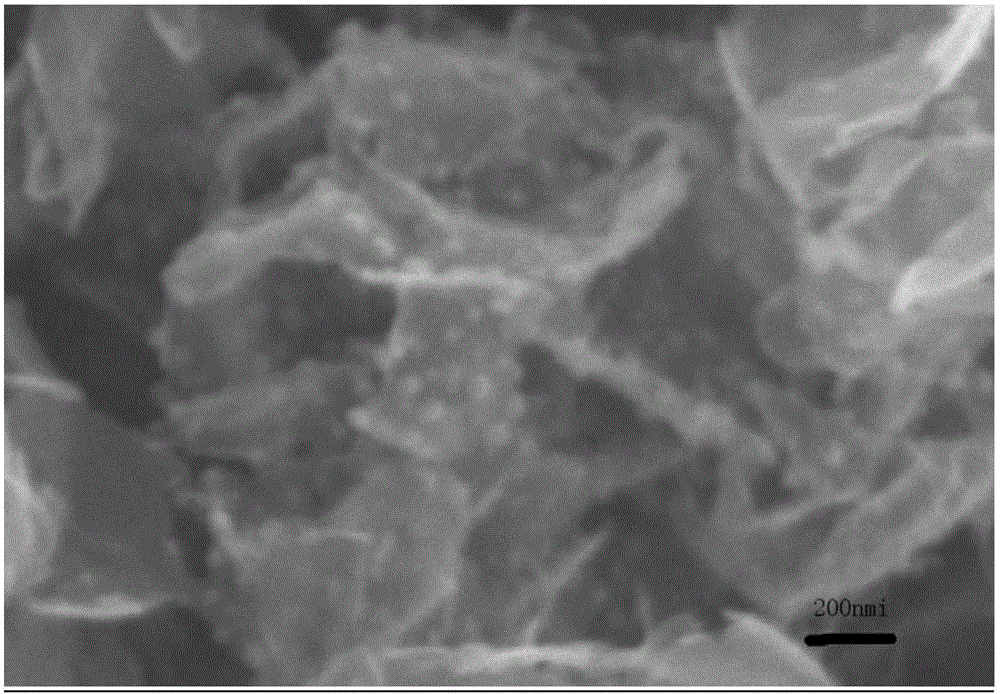

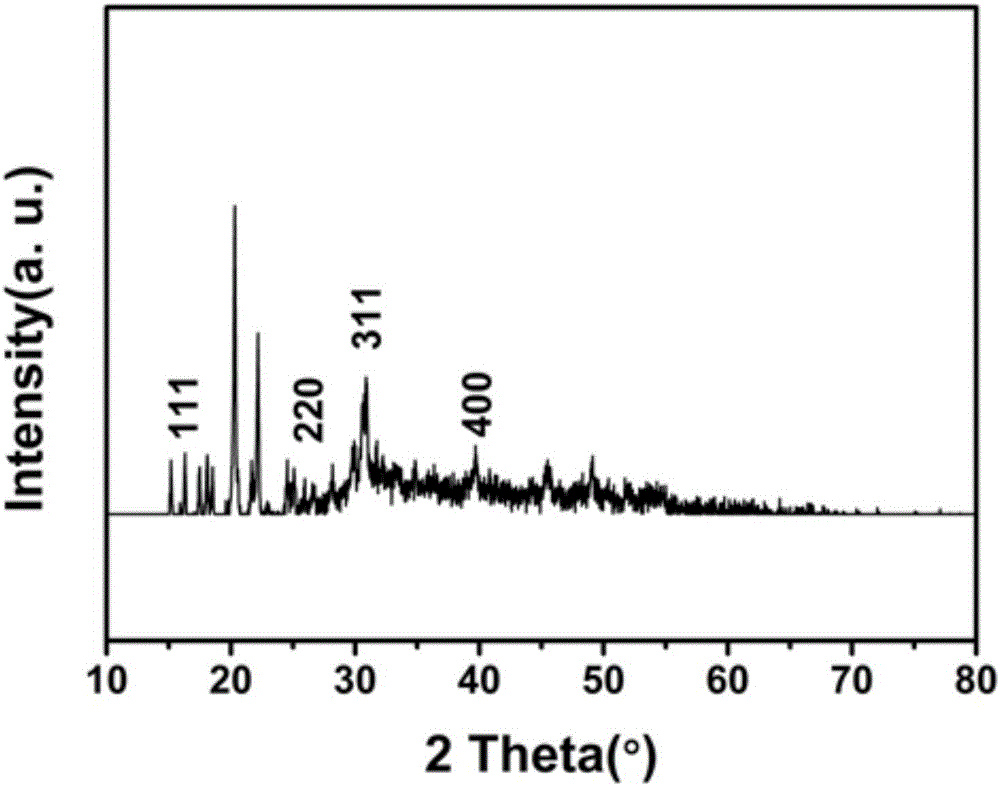

[0021] A kind of preparation method of nickel sulfide / graphene / polyaniline composite electrode material of the present invention, the steps are as follows:

[0022] Add 0.3ml of aniline and 10mg of sodium lauryl sulfate into 50ml of water for ultrasonic dispersion, mix the dispersed aniline solution with 60ml (0.5mg / ml) of GO dispersion, and continue ultrasonication for 15min to form a stable and uniform mixture solution, stirred in an ice-water bath, and then acidified 0.7g of ammonium persulfate with 50ml (1mol / L) HCl, the solution gradually turned dark green, kept stirring in an ice-water bath for 12 hours, and then the obtained solution was centrifuged and washed 3 times with water to obtain a gel Then, ultrasonically disperse it in 180ml water, add 10ml (1mol / L) HCl dropwise therein, slowly add 600mg of nickel acetate tetrahydrate and 300mg of thioacetamide while sonicating, and then mix the resulting mixture Put it into a hydrothermal kettle, react at 180° C. for 12 hour...

Embodiment 2

[0024] A kind of preparation method of nickel sulfide / graphene / polyaniline composite electrode material of the present invention, the steps are as follows:

[0025] Add 0.2ml of aniline and 8mg of sodium lauryl sulfate into 50ml of water for ultrasonic dispersion, mix the dispersed aniline solution with 30ml (0.5mg / ml) of GO dispersion, and continue ultrasonication for 15min to form a stable and uniform mixture solution, stirred in an ice-water bath, and then acidified 0.35g of ammonium persulfate with 25ml (1mol / L) HCl, the solution gradually turned dark green, kept stirring in an ice-water bath for 12 hours, and then the obtained solution was centrifuged and washed 3 times with water to obtain a gel Then, ultrasonically disperse it in 90ml of water, add 5ml (1mol / L) HCl dropwise therein, slowly add 300mg of nickel acetate tetrahydrate and 150mg of thioacetamide dropwise while ultrasonically, then the obtained mixed solution Put it into a hydrothermal kettle, react at 180° C....

Embodiment 3

[0027] A kind of preparation method of nickel sulfide / graphene / polyaniline composite electrode material of the present invention, the steps are as follows:

[0028] Add 0.1ml of aniline and 6mg of sodium lauryl sulfate into 50ml of water for ultrasonic dispersion, mix the dispersed aniline solution with 20ml (0.5mg / ml) of GO dispersion, and continue ultrasonication for 10min to form a stable and uniform mixture solution, stirred in an ice-water bath, and then acidified 0.5g of ammonium persulfate with 50ml (1mol / L) HCl, the solution gradually turned dark green, kept stirring in an ice-water bath for 10 hours, and then the obtained solution was centrifuged and washed 3 times with water to obtain a gel Among them, during the ultrasonic and stirring process, keep the water temperature at 0-5°C; then ultrasonically disperse it in 180ml of water, add 10ml (1mol / L) HCl dropwise, and slowly add 420mg of acetic acid tetrahydrate while ultrasonically Nickel and 210 mg of thioacetamide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com