Ag/TiO2-N visible-light catalyst, and supercritical alcohol-heating preparation method and application thereof

A photocatalyst and visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, botanical equipment and methods, etc., can solve the problem that Ag particles cannot be loaded synchronously, the probability of carrier recombination is increased, and the particle size is difficult to control. and other problems, to achieve the effect of simple and easy preparation method, uniform distribution and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

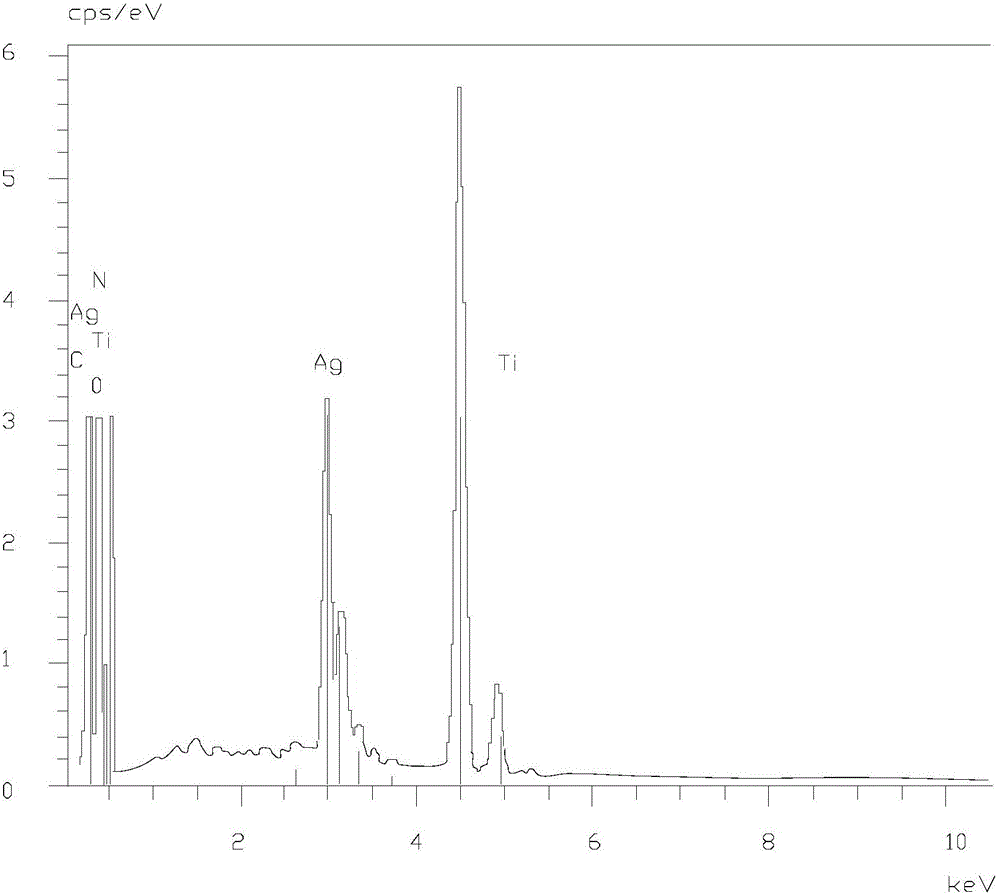

[0028] A Ag / TiO 2 -N visible photocatalyst, the crystal form of titanium dioxide is pure anatase phase, the particle size is 2.0-3.0μm, and the specific surface area is 140-169m2 / g.

[0029] The supercritical alcohol thermal preparation method of Ag / TiO2-N visible light catalyst comprises the following steps:

[0030] (1), TiO 2 Preparation of nanoparticles: Add tetrabutyl titanate to the ethanol solution and stir, then place the solution in a supercritical kettle, and inject ethanol into the kettle, after the supercritical reaction, wash the obtained product with ethanol and deionized water Dry to get TiO 2 Nanoparticles;

[0031] (2), Ag / TiO 2 -N visible photocatalyst preparation: Weighing AgNO 3 Add it into ultrapure water, add ammonia solution drop by drop, make silver ammonia solution and add it to TiO 2 The ethanol suspension is placed in a supercritical kettle, and ethanol is injected into the kettle. After the supercritical reaction, it is naturally cooled to roo...

Embodiment 1

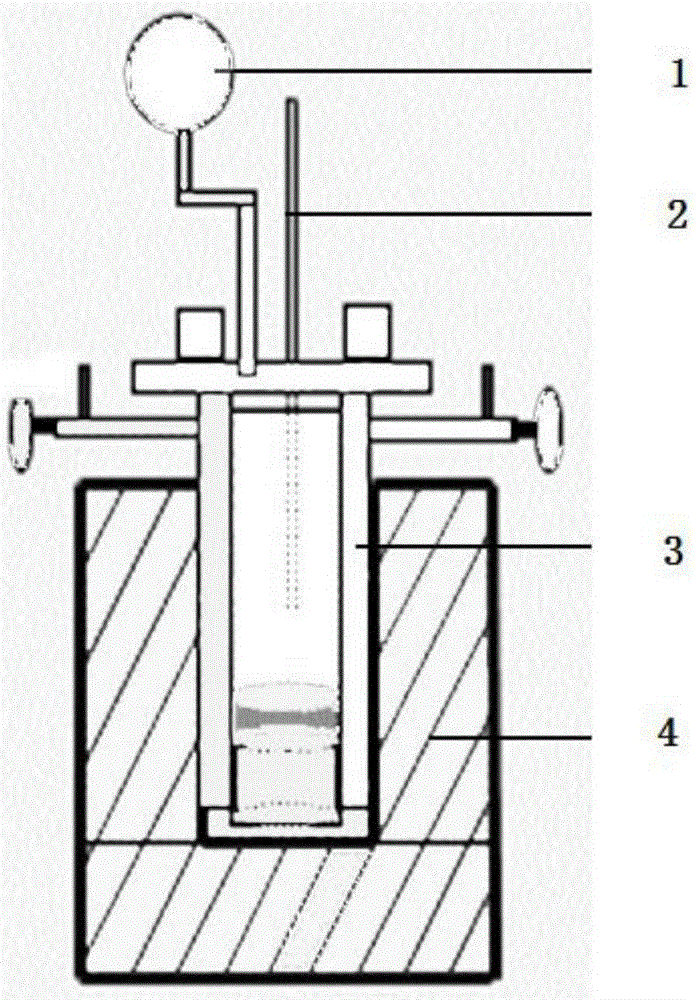

[0039] Add 10mL tetrabutyl titanate to 30mL ethanol solution and stir for 30min, then place the solution in a 500mL supercritical kettle (such as figure 1 ), which includes a kettle lining 3, and a heating furnace 4 is arranged on the outside of the kettle lining, and the kettle lining is sealed by a sealing cover, and a temperature sensing rod 2 and a pressure gauge 1 are fixed on the sealing cover, and The temperature and pressure in the lining of the kettle were monitored by temperature sensing rods and pressure gauges, and 170mL of ethanol was injected into the kettle, and the temperature was raised to 240°C and kept for 70 minutes at a heating rate of 2°C / min. The obtained product was washed three times with ethanol and deionized water respectively, then centrifuged and dried at 80° C. for 24 hours. TiO nanospheres can be obtained 2 . Weigh 0.046gAgNO 3 Add it to 10mL ultrapure water, add 0.8mL ammonia solution drop by drop, and add it to 30mL TiO 2 In ethanol suspens...

Embodiment 2

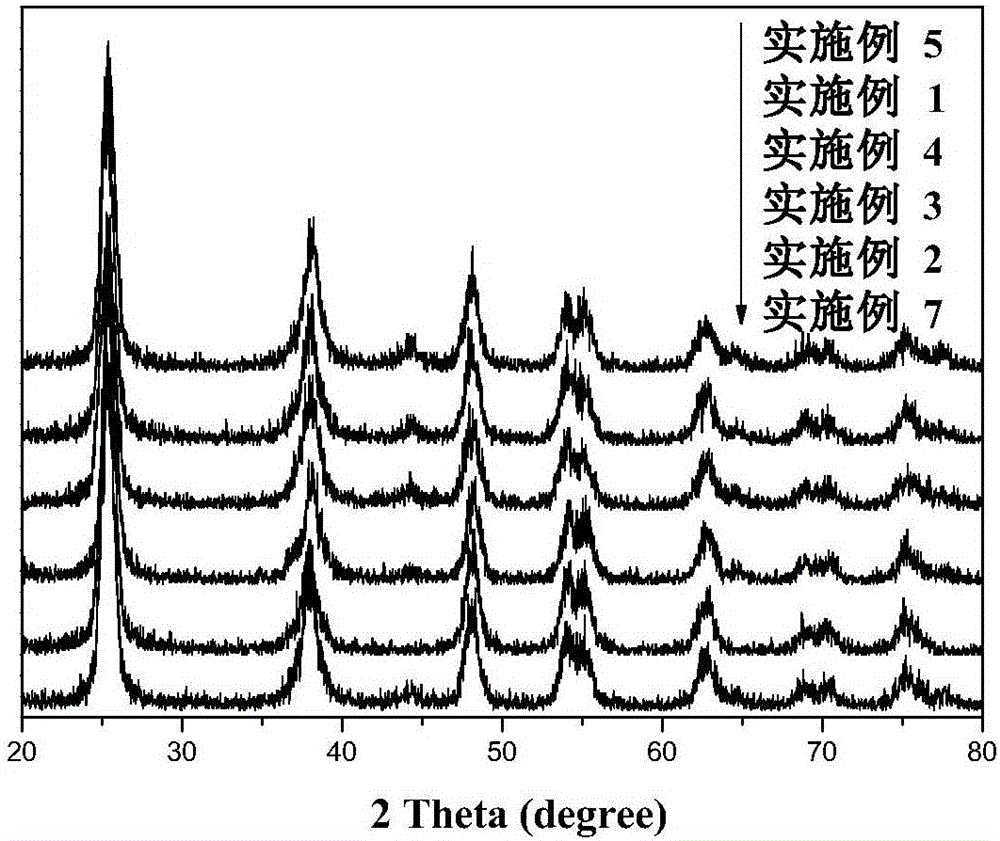

[0042] No AgNO was added during preparation 3 , the rest of the content is the same as that described in Example 1, that is, to obtain spherical TiO 2 -N photocatalyst. figure 2 The XRD collection of illustrative plates of middle present embodiment shows that obtained TiO 2 The -N photocatalyst is an anatase crystal phase without impurities. The specific surface area of the present embodiment is 169m 2 / g. Figure 5 This example has a certain catalytic activity in the catalytic degradation of methyl orange under visible light. Figure 9 In this example, there is no obvious photocatalytic killing performance on Acinetobacter baumannii under visible light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com