Patents

Literature

53results about How to "Dense thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polysulfonamide nanofiltration or reverse-osmosis composite membrane, and preparation method thereof

InactiveCN107126850AHigh desalination rateImprove desalination propertiesMembranesGeneral water supply conservationSulfonyl chlorideReverse osmosis

The invention discloses a polysulfonamide nanofiltration or reverse-osmosis composite membrane, and a preparation method thereof. the preparation method for the polysulfonamide nanofiltration or reverse-osmosis composite membrane comprises the following steps: pretreatment of a porous supporting membrane; alternate layer-upon-layer assembling of a sulfonyl chloride organic-phase solution and a polyamine water-phase solution on the surface of the porous supporting membrane via reaction; heat treatment; etc.; wherein heat treatment can be carried out during or after layer-upon-layer assembling. Nanoparticles, a surfactant, a catalytic acid absorbent or catalyst, a pore forming agent and other additives are added into the sulfonyl chloride organic-phase solution and the polyamine water-phase solution. The polysulfonamide nanofiltration or reverse-osmosis composite membrane prepared by using the method has improved desalination performance and acid resistance, smoother surface and lower roughness compared with composite membranes prepared through traditional interfacial polymerization, and has good application prospects in the fields of nanofiltration and reverse osmosis.

Owner:青岛致用新材料科技有限公司

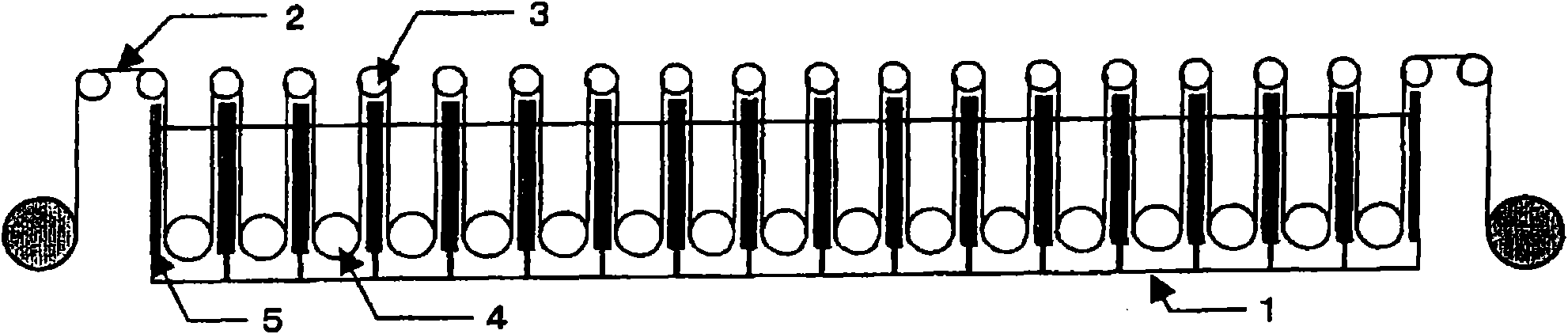

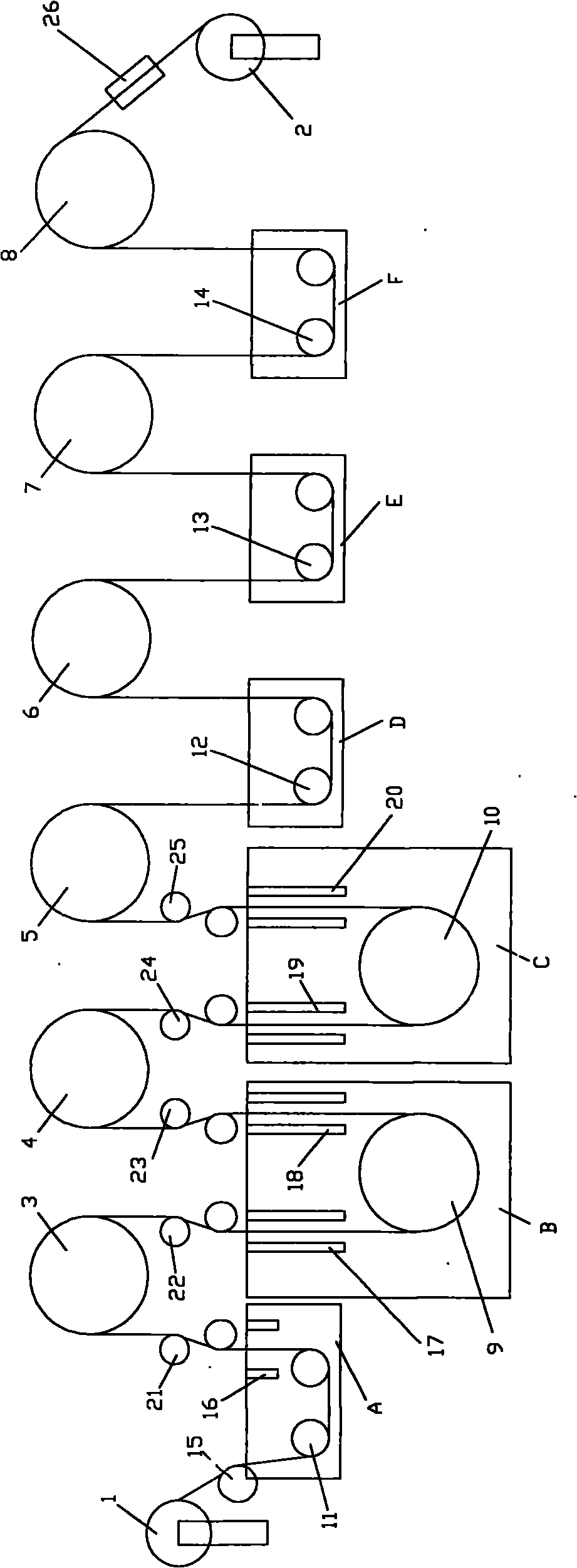

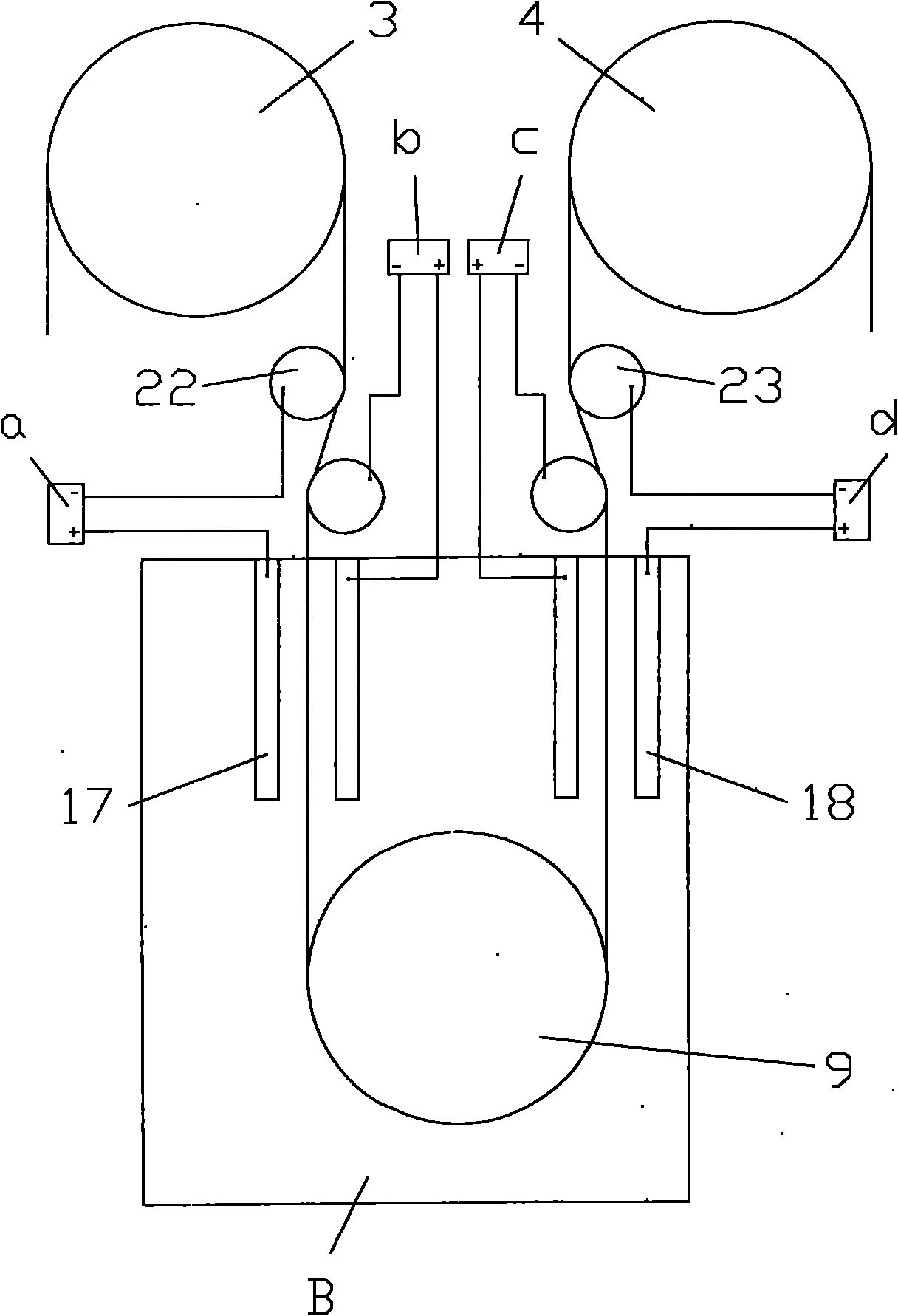

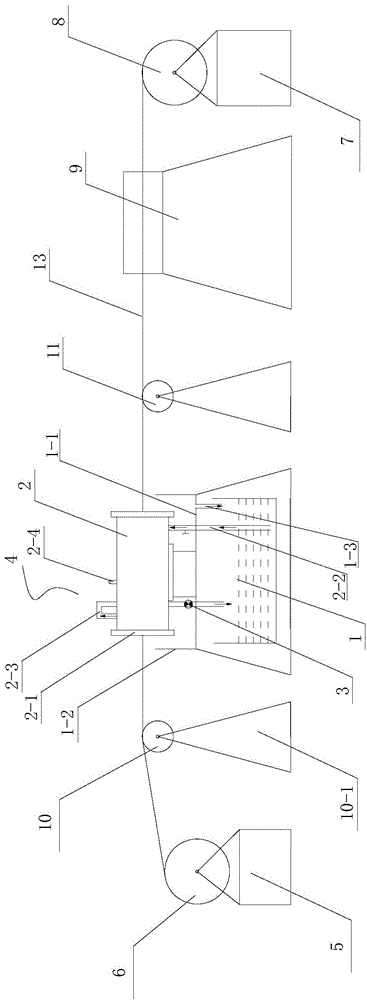

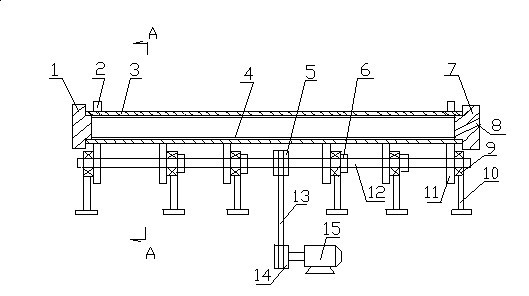

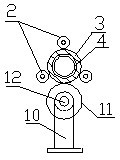

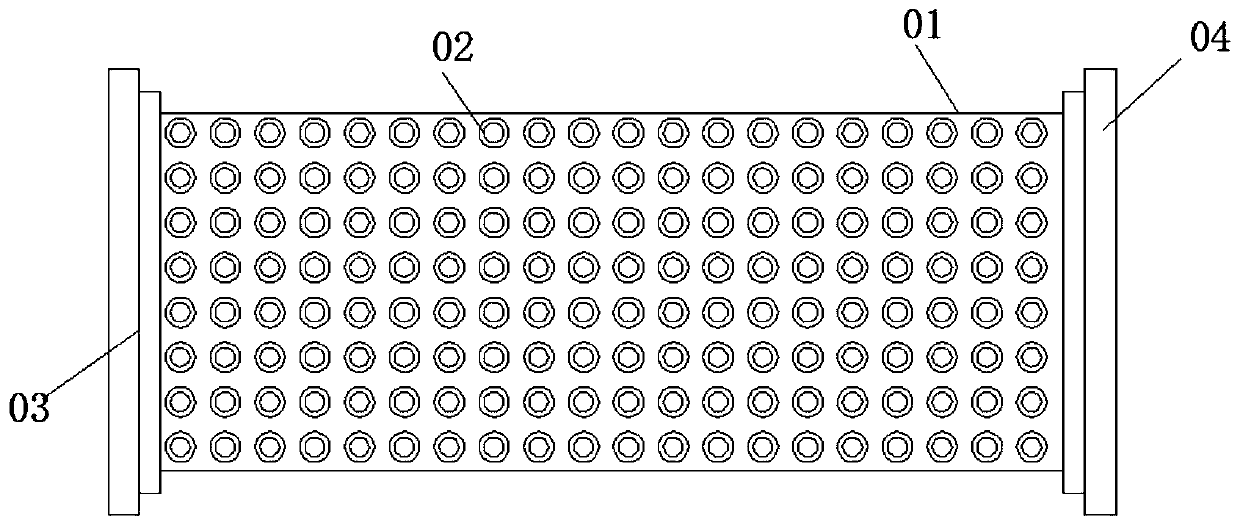

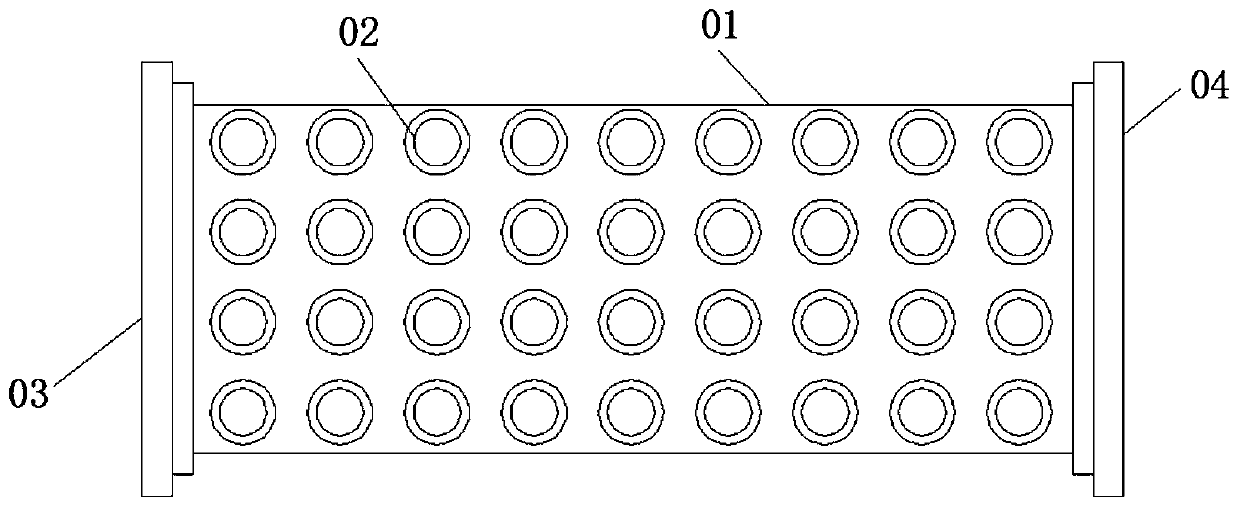

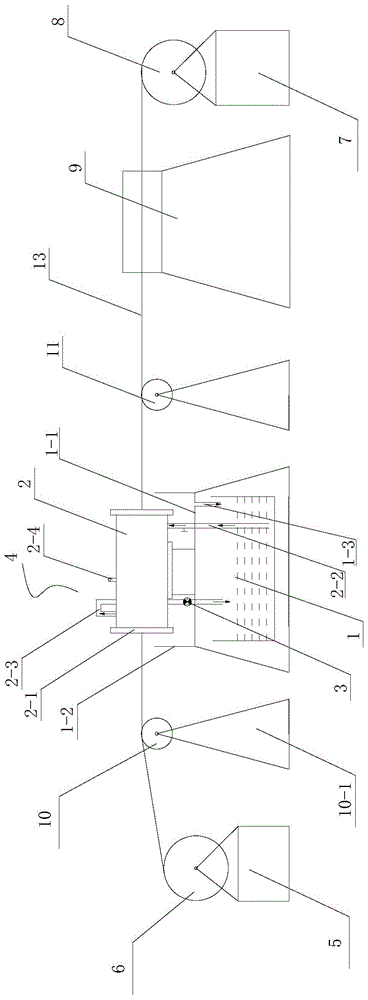

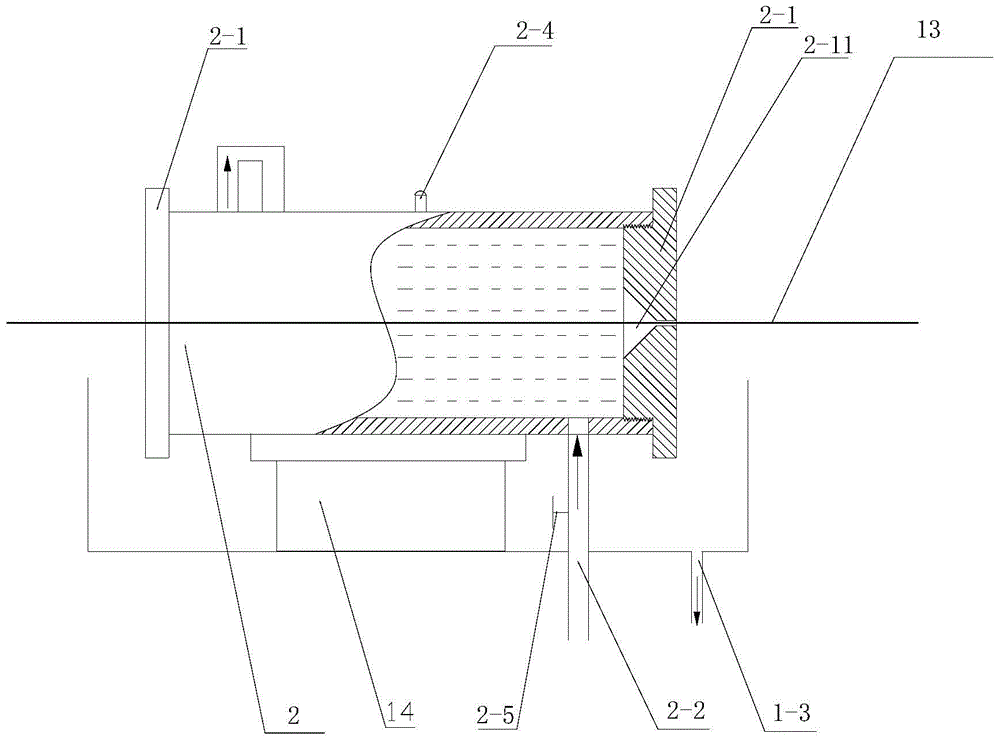

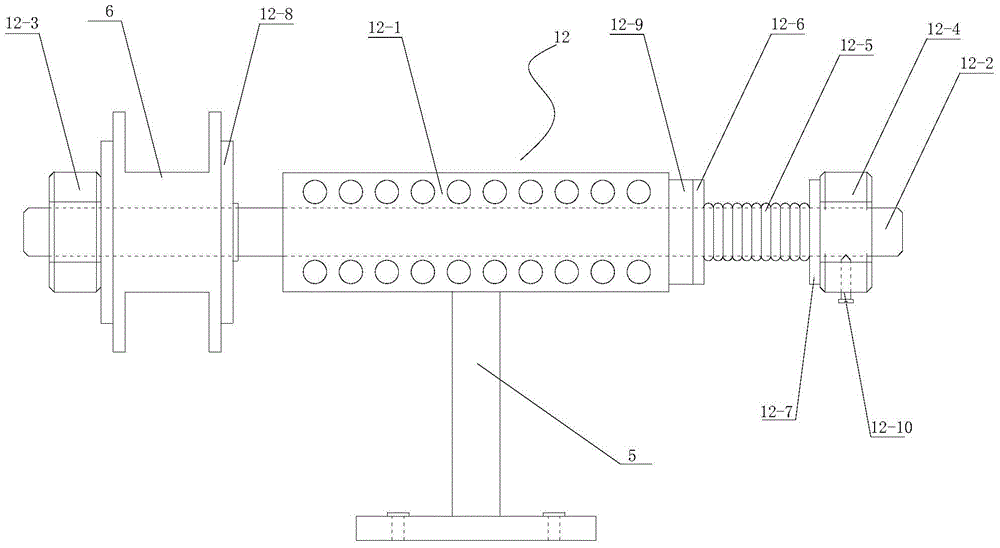

Continuous plating device for films and method for performing continuous plating on films

The invention provides a continuous plating device for films. The plating device comprises an unwinding machine, a winding machine, at least one main plating bath, a plurality of pairs of horizontal first conductive roller groups parallel to each other and a rectifier; a plurality of pairs of first anode groups parallel to each other and at least one first guide roller group parallel to the conductive rollers of the first conductive roller groups are non-horizontally arranged in the main plating bath; the conductive rollers of the first conductive roller groups are arranged above the main plating bath and correspond to the anodes of the first anode groups; and each pair of conductive rollers of the first conductive roller groups comprises two adjacent conductive rollers. The invention also provides a method for performing continuous plating on the films. When the continuous plating device is adopted to perform continuous plating on the films, any one or two surfaces of each film can be plated selectively at the same time, and therefore the flexibility of the plating operation and the production efficiency are improved.

Owner:ZHUHAI CHUANGYUAN KAIYAO ELECTRONICS MATERIAL CO LTD

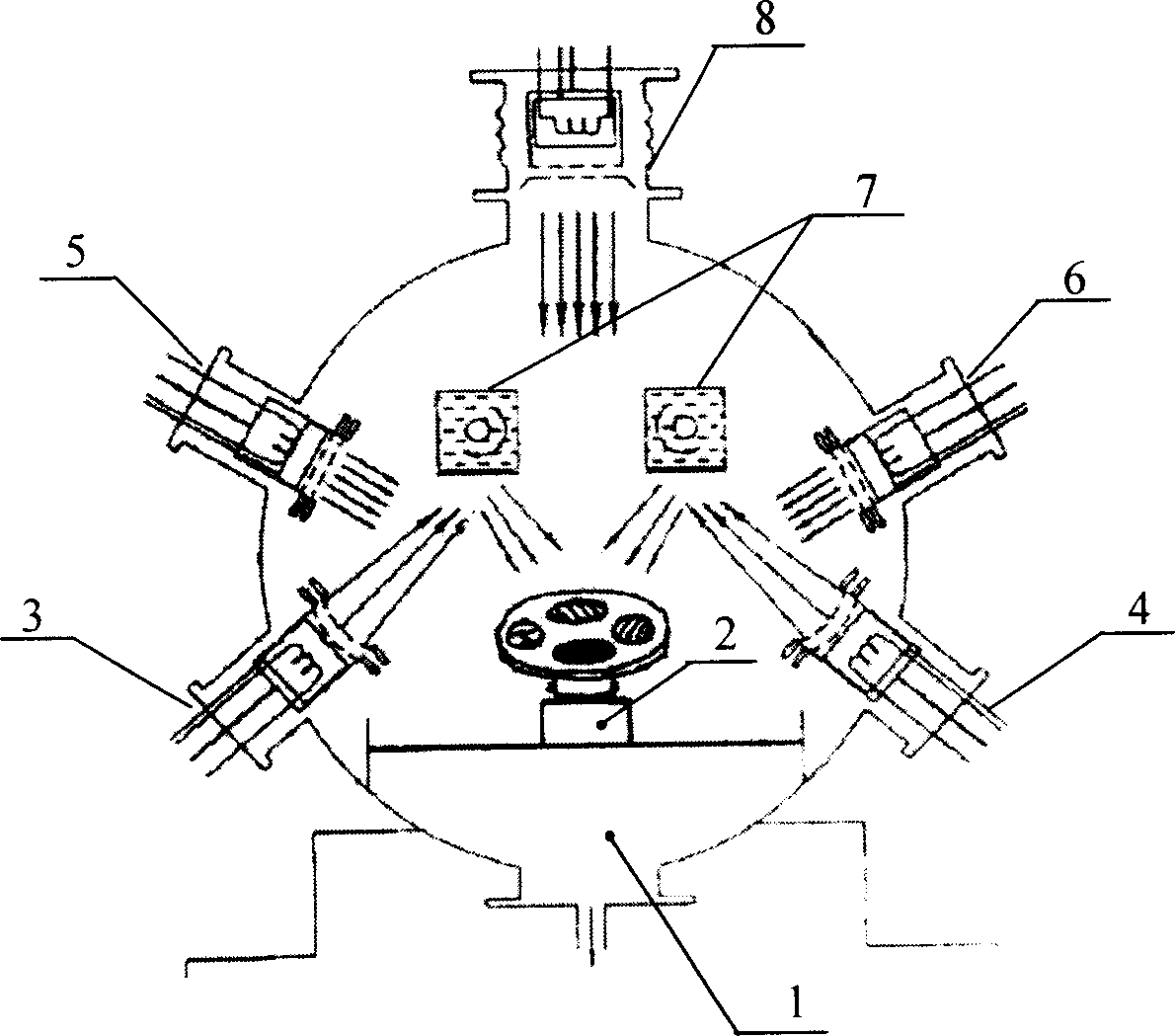

Method for preparing silver-enriched antibacterial film on pyrolytic carbon and TiN film for medical use

InactiveCN1827840AIncrease concentrationImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingSputteringHigh energy

The invention relates the method for preparing rich silver antibiotic film used for medical pyrolytic carbon and TiN film. It solves the antibiosis question. The method comprises the following steps: on the pyrolytic carbon: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d injecting silver ion: 70, 30keV energy, 2-8mA beam current, 2X1014 / cm2-3X1014 / cm2 dosage, and forming rich silver antibiotic film and antibiosis ratio being 100%; on TiN film: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d sputtering Ti target with 3keV, 80mA Ar+ ion, 20-40keV, beam current: bombarding with 2-8mA high-energy N+ ion for 10-20 minutes; 50-350eV, beam current: bombarding with 10-30mA low-energy N+ ion for 60-180 minutes to deposit, N2 air pressure being 8X10 3Pa; e injecting silver ion: 30-80keV, beam current: 2-8mA, 1X1017 / cm2-5X1018 / cm2 dosage, forming rich silver antibiotic film and antibiosis ratio being 90%. The film has the advantages of good abradability, strong adhesive force and anti-corrosion, good cell compatibility and long antibiosis time-effect. The film can be used to prepare artificial heart valve and hard tissue alternate material which is implanted in human.

Owner:TIANJIN NORMAL UNIVERSITY

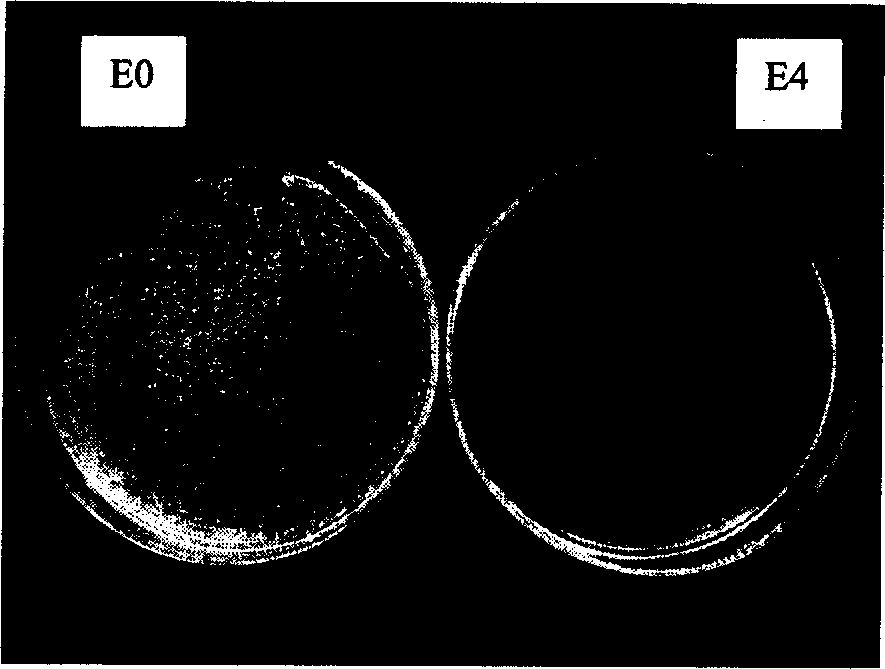

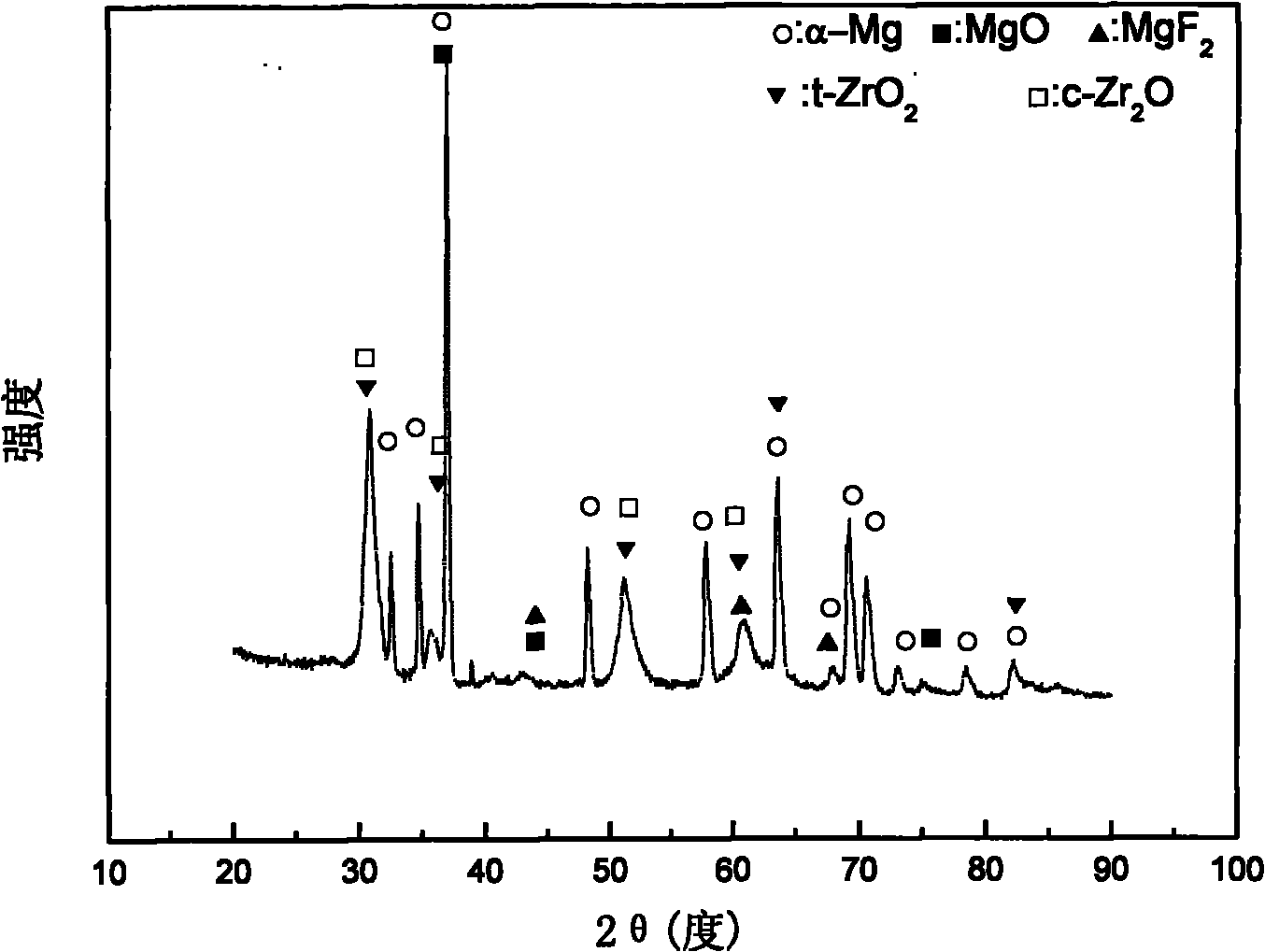

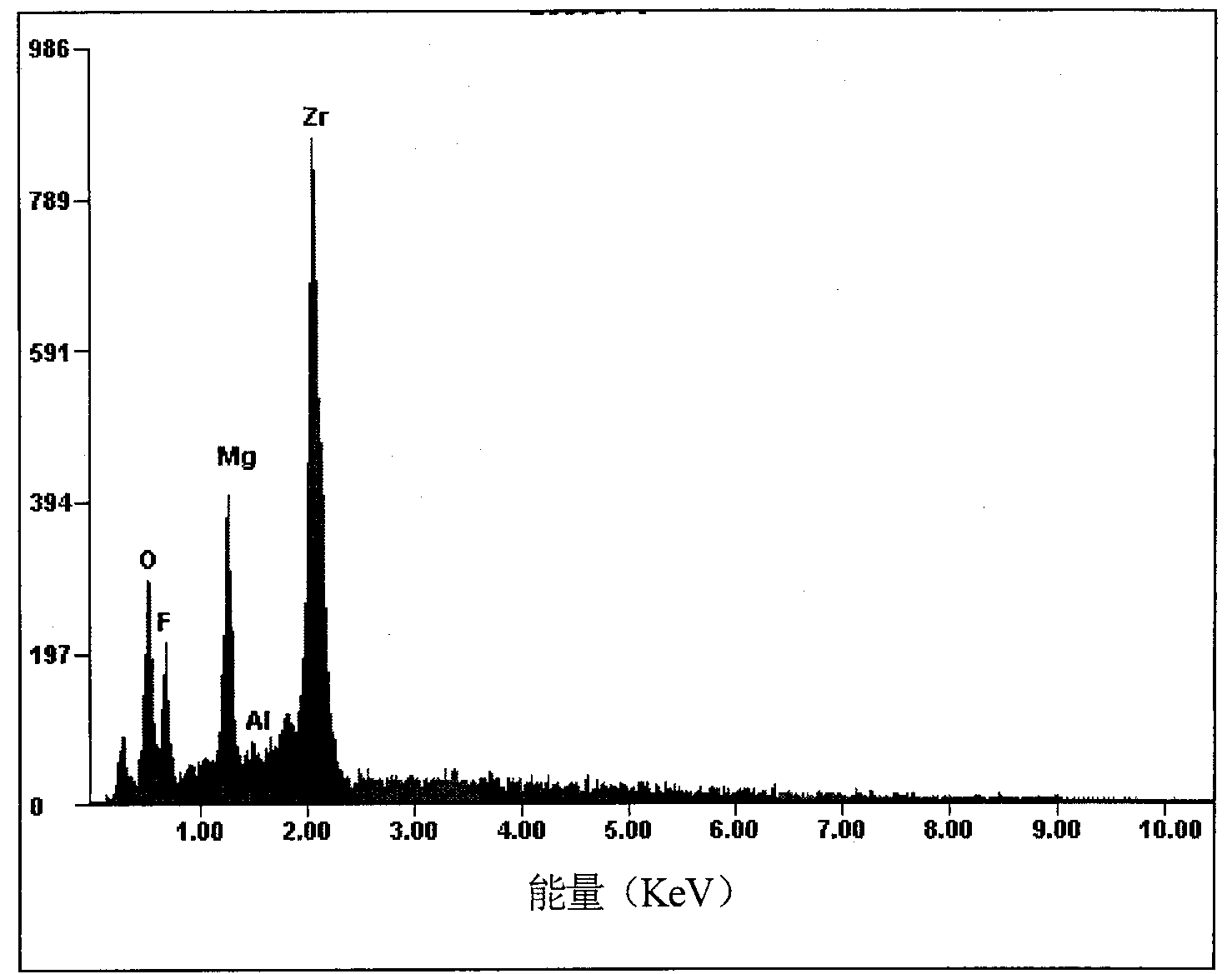

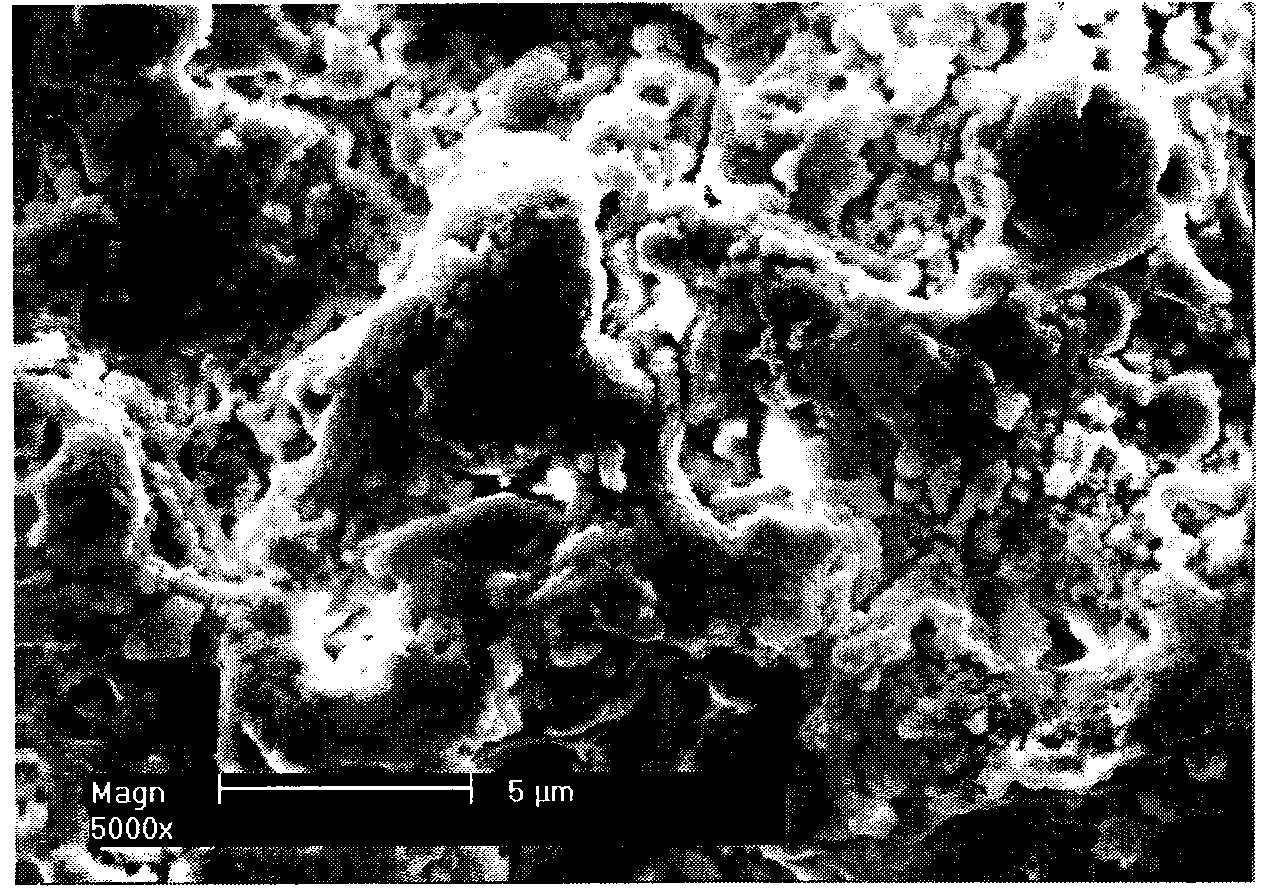

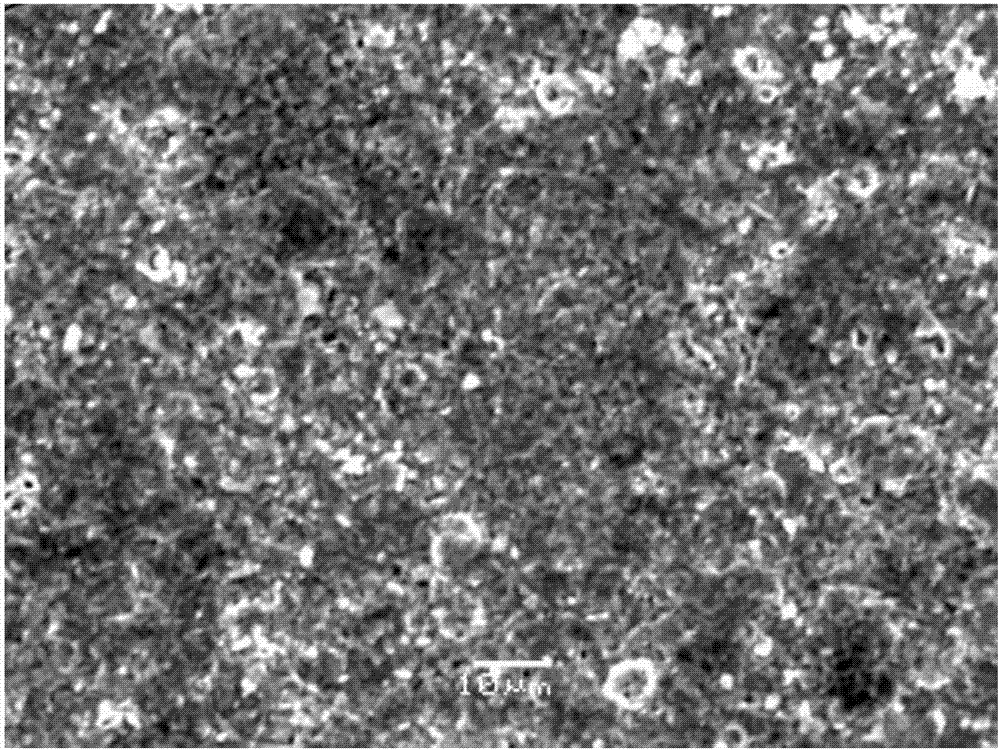

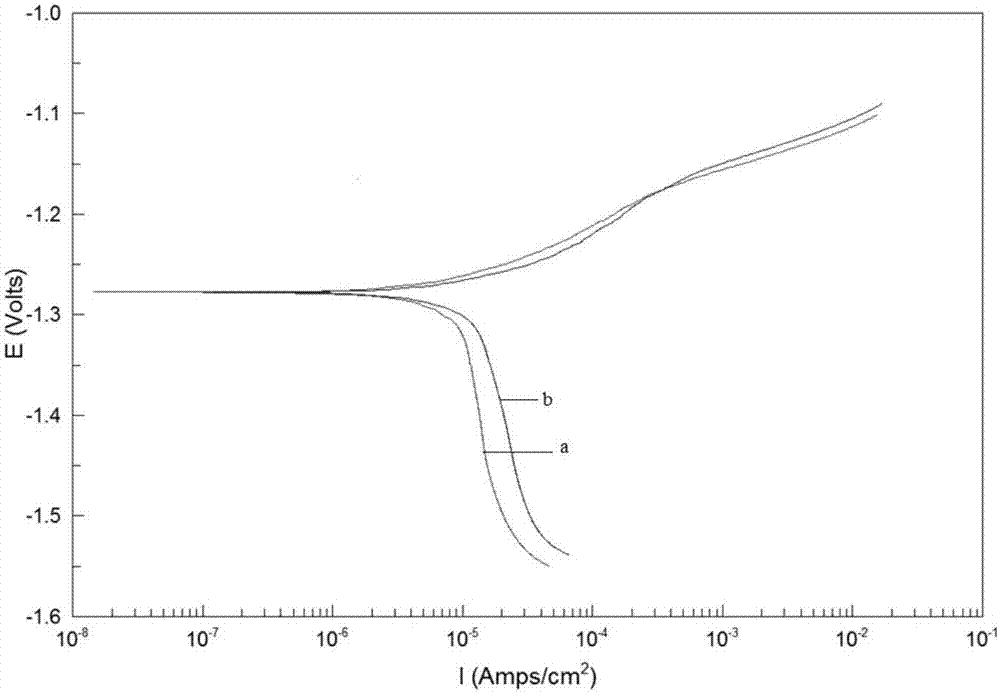

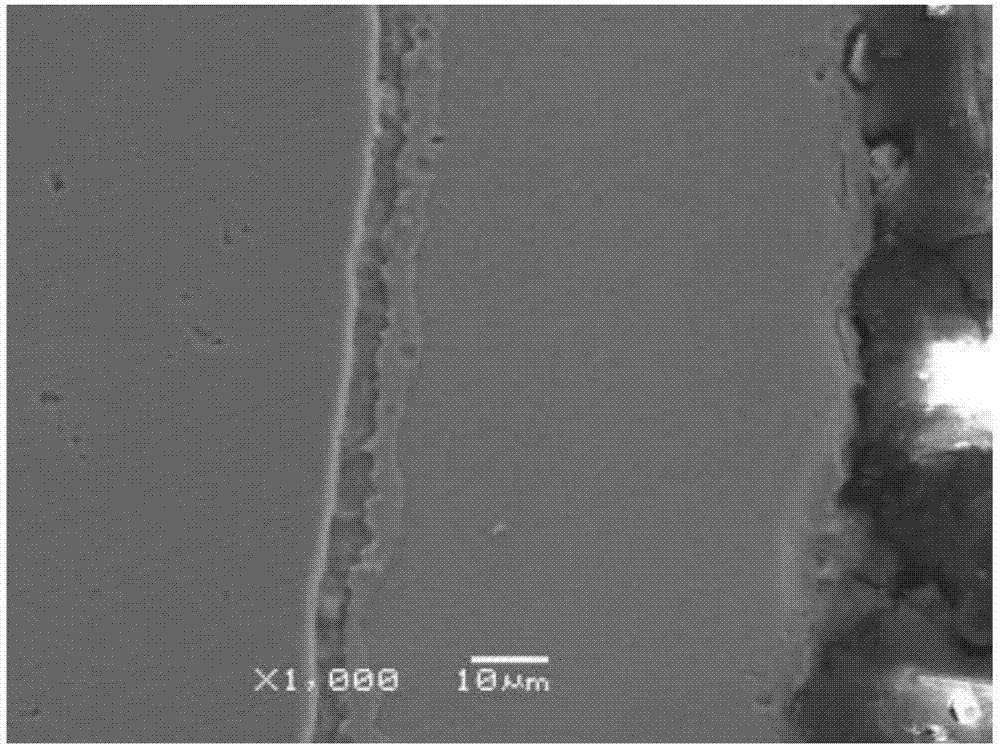

Highly corrosion-resistant ceramic coating solution prepared through magnesium alloy surface micro-arc oxidation and application thereof

ActiveCN101994145ASimple ingredientsEasy to controlAnodisationMicro arc oxidationCorrosion resistant

The invention relates to magnesium alloy surface treatment technology, in particular to highly corrosion-resistant ceramic coating solution prepared through magnesium alloy surface micro-arc oxidation and application thereof. The defects that a magnesium alloy workpiece has a relatively rough surface after being subjected to micro-arc oxidation treatment in fluorozirconate and is severely corroded in oxidizing solution are overcome. 1L of micro-arc oxidizing solution consists of 6 to 12g of fluorozirconate, 2 to 10g of dihydric phosphate, 2 to 8g of fluoride and 2 to 10g of citrate. A method for preparing a composite ceramic coating by using the solution comprises the following step of: treating a magnesium alloy workpiece subjected to pretreatment and the conventional micro-arc oxidation treatment respectively in the micro-arc oxidizing treatment solution to obtain the composite ceramic coating. Compared with the conventional magnesium alloy micro-arc oxidation coating, the composite ceramic coating has higher corrosion resistance, uniform thickness and low surface roughness, is compact and does not need aftertreatment such as sealing and the like; and the solution has simple components and is suitable for industrial production, and the raw materials are readily available.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

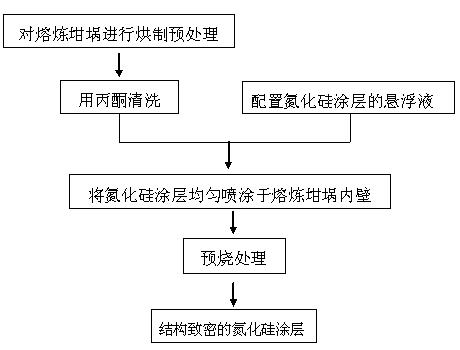

Preparation method of coating for melting crucible

InactiveCN102221293AExcellent adhesionMeet the use requirementsPretreated surfacesCrucible furnacesCrucibleIngot

The invention belongs to the technical field of coating preparation. A preparation method of a coating for a melting crucible comprises the following steps of: pre-drying the melting crucible; preparing a suspension by adopting a PVP (Polyvinyl Pyrrolidone) absolute ethanol solution and silicon nitride; uniformly spraying the suspension on the inner wall of the melting crucible; and pre-burning the melting crucible with sprayed coating to form a silicon nitride coating with uniform thickness and compact structure on the inner wall of the melting crucible. The method has the advantages that: the melting crucible is pre-dried and cleaned before being sprayed to contribute to adhesion of the coating; the PVP absolute ethanol solution is added to the suspension of the coating, the absolute ethanol is evaporated after the crucible is dried, the adhesive PVP leads the coating to be adhered on the inner wall of the crucible, and the coating has higher adhesive force, so that the crucible is prevented from reacting with and adhering melt, smooth demolding of ingots is realized, impurities are prevented from entering melt, the purification effect of the melt is realized, and the using requirement for the coating in a casting process is fulfilled.

Owner:DALIAN UNIV OF TECH

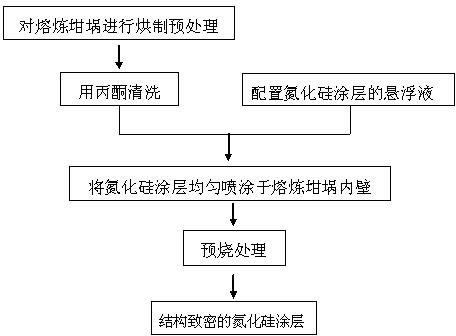

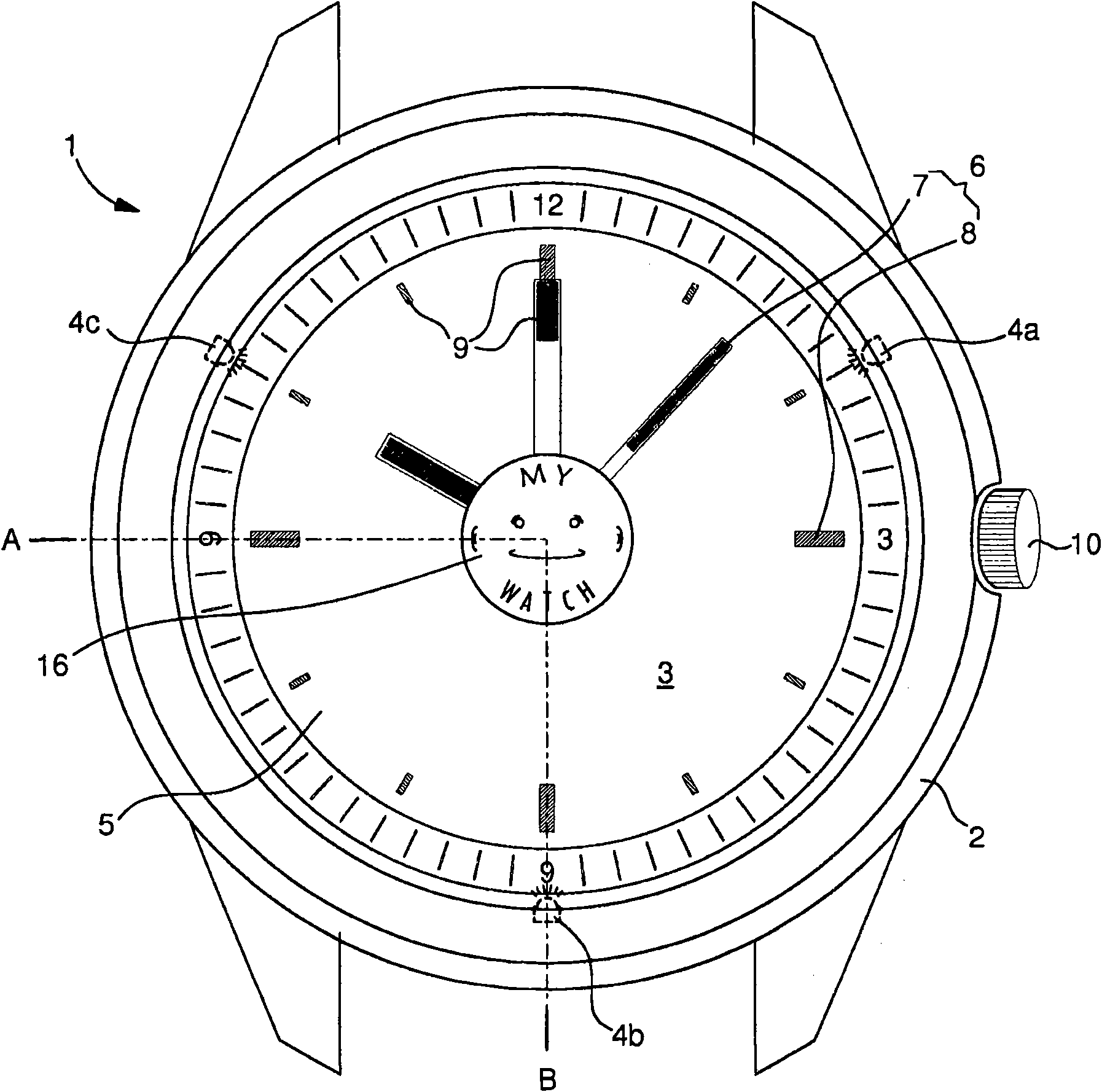

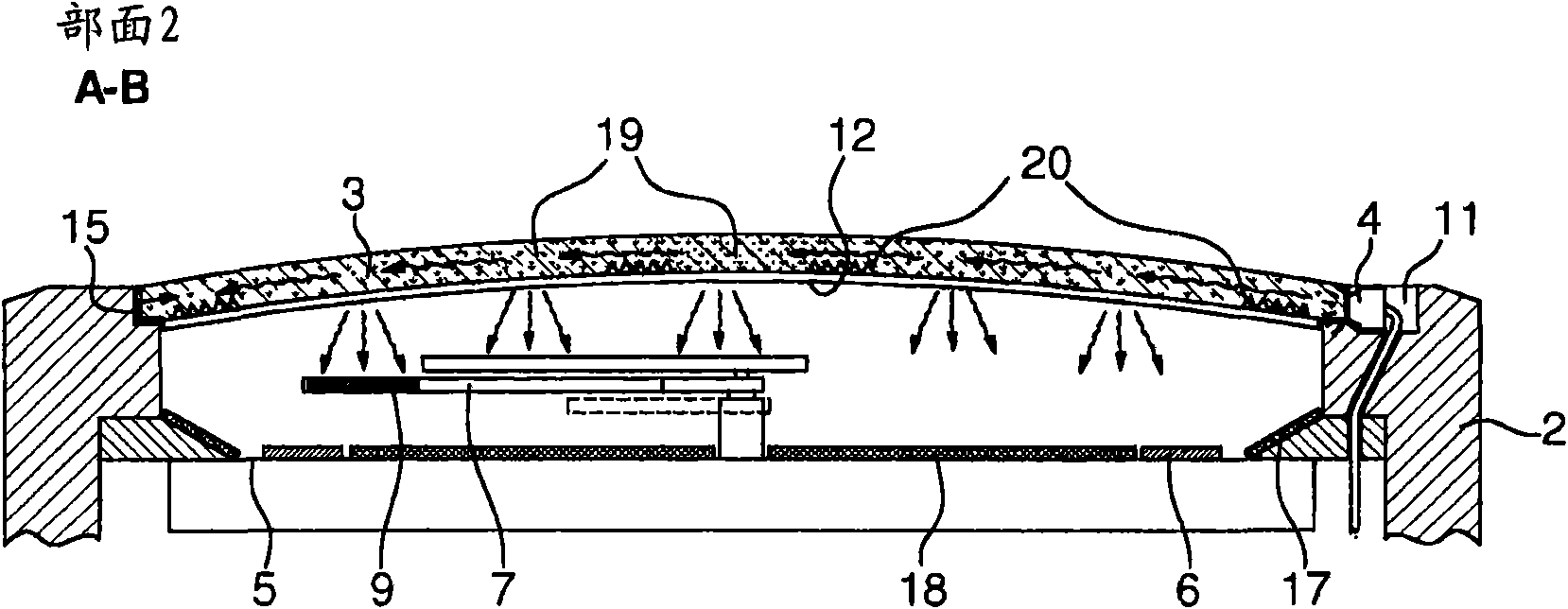

Timepiece with a lighting device comprising an ultraviolet led

InactiveCN101663625AImprove visibilityDense thicknessVisual indicationVisual indicationsEffect lightUltraviolet

The invention relates to a timepiece (1) comprising a glass (3) having an inner face and an outer face relative to the timepiece, and a lighting device (4) including at least one ultraviolet or infrared LED (4a) for lighting at least one area (9) comprising fluorescent and / or phosphorescent pigments of an indicator member (7) that can be viewed through the glass, characterised in that said LED isprovided on the periphery of the glass defining a wave guide capable of scattering ultraviolet or infrared light, and in that scattering means (12; 13; 15; 19; 20) for scattering the ultraviolet or infrared light from the glass towards the inside of the timepiece are provided on the ultraviolet or infrared light path.

Owner:ETA SA MFG HORLOGERE SUISSE

Method for preparing micro-arc oxidation film with photocatalysis function

The invention belongs to the field of surface treatment technologies, and particularly relates to a method for preparing a micro-arc oxidation film with a photocatalysis function. The method comprises steps of performing pretreatment, water scrubbing, configuration of micro-arc oxidation tank liquor, micro-arc oxidation, water scrubbing and the like on a matrix. By adopting the method, the film with the photocatalysis function can be directly prepared on the surface of a light alloy through a micro-arc oxidization method. The method has simple technologies, and avoids complex pretreatment and aftertreatment processes. The prepared film can be firmly combined with the matrix and has the photocatalysis function.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

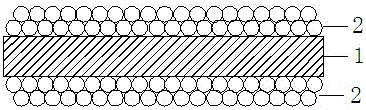

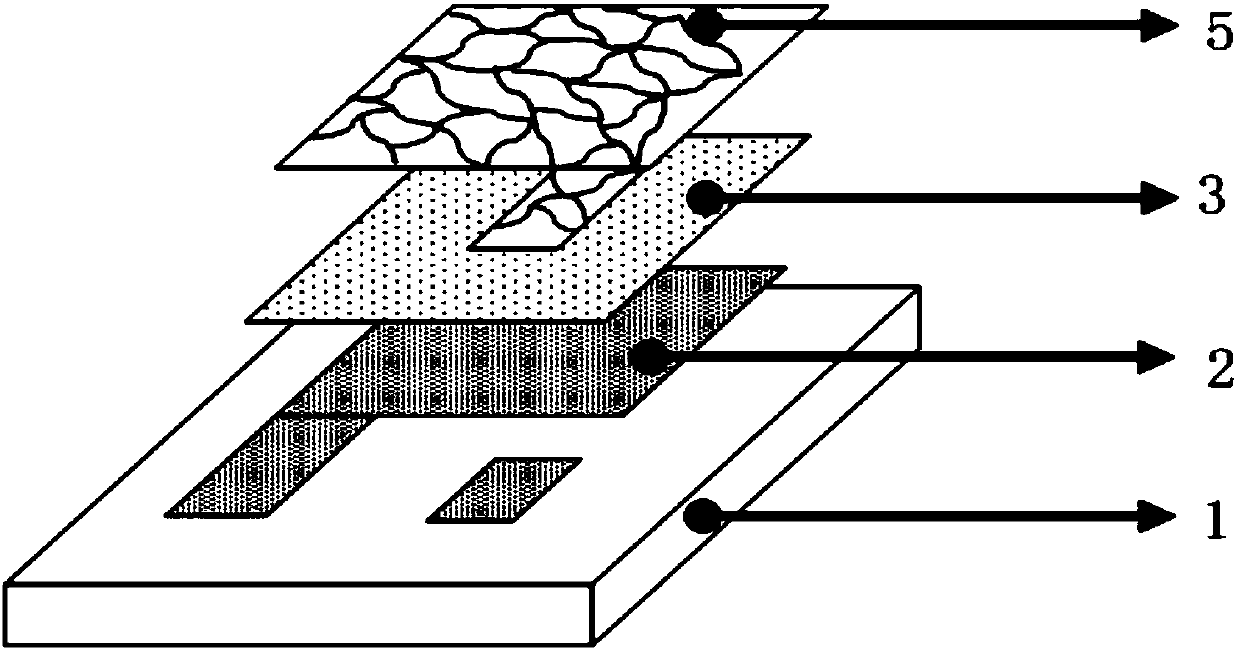

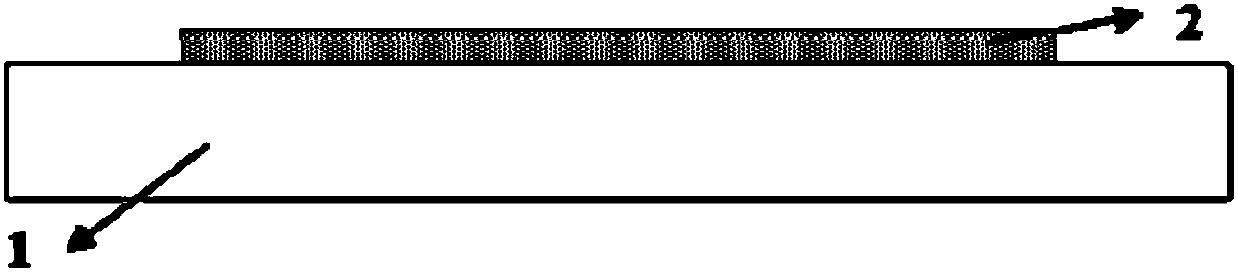

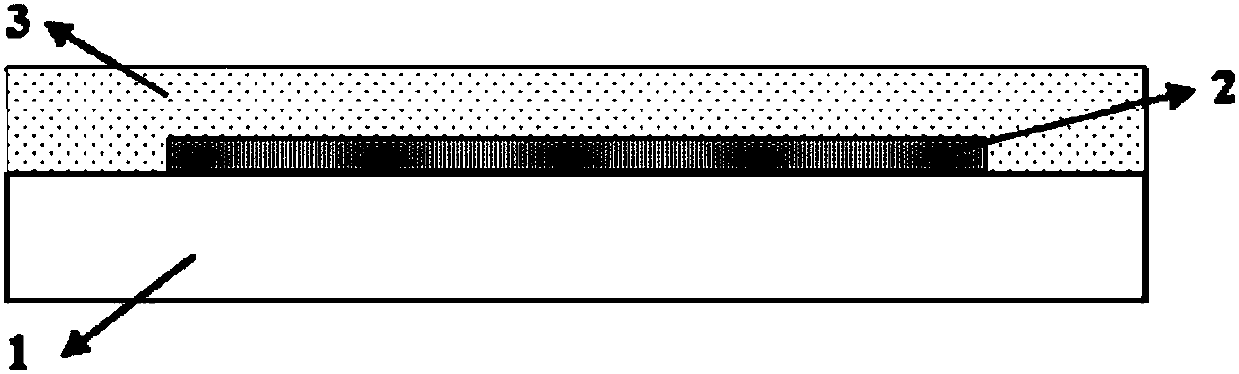

Lithium ion battery ceramic diaphragm coated with polyvinylidene fluoride, and preparation method therefor

InactiveCN105845873AImprove securityHigh decomposition temperatureCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a lithium ion battery ceramic diaphragm coated with polyvinylidene fluoride. The lithium ion battery ceramic diaphragm comprises a base material diaphragm, wherein at least one surface of the base material diaphragm is coated with ceramic slurry; the ceramic diaphragm is prepared by the following steps of mixing and dispersing polyvinylidene fluoride and a dispersing agent at a weight ratio of 1 to 0.1-50 to obtain a dispersion glue solution; mixing and dispersing the dispersion glue solution and ceramic granules at a weight ratio of 1 to 0.1-10 to obtain ceramic slurry; and uniformly coating the surface of the base material diaphragm with the ceramic slurry, and drying the base material diaphragm to obtain the lithium ion battery ceramic diaphragm coated with polyvinylidene fluoride. The surface of the base material diaphragm of the lithium ion battery is coated with the ceramic diaphragm of polyvinylidene fluoride and ceramic granules, wherein the ceramic diaphragm is 0.1-10um in thickness; the ceramic diaphragm is compact in surface and uniform in thickness; polyvinylidene fluoride has a relatively high decomposition temperature, so that the diaphragm can be protected when the surface of the base material diaphragm is coated with the polyvinylidene fluoride; and therefore, the thermal resistance of the diaphragm is improved, so that the safety performance of the lithium ion battery is further improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

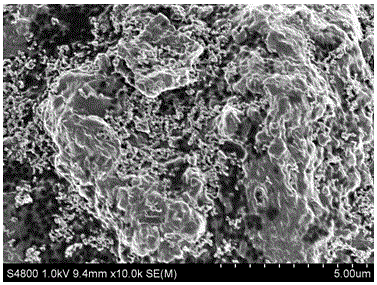

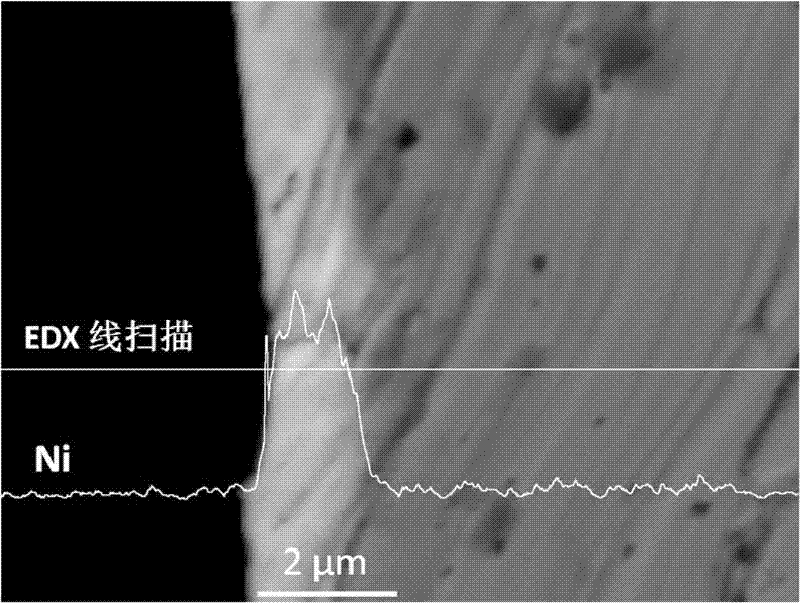

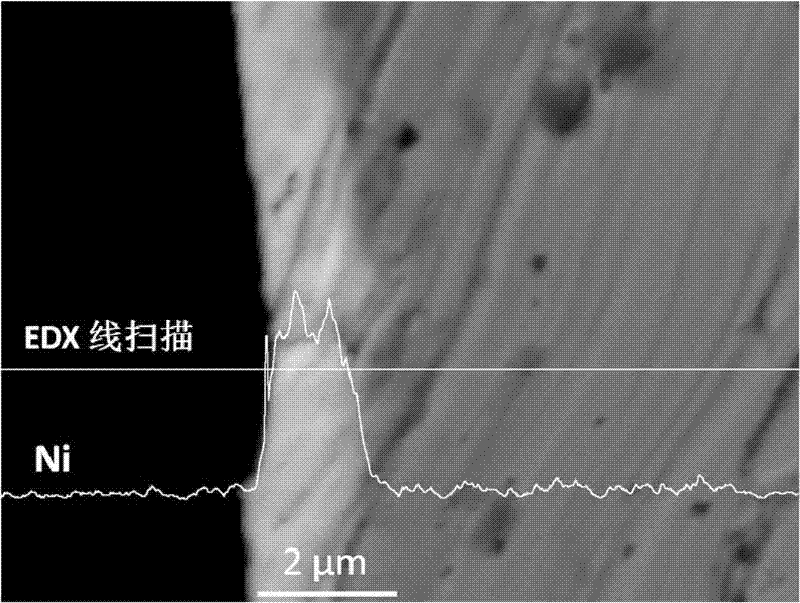

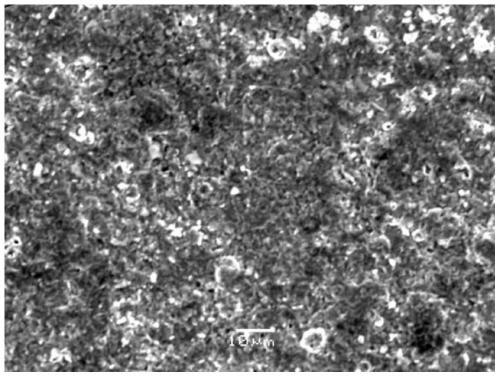

Pulse electrochemical deposition and tissue adjustment processes for nickel plating copper belt

The invention discloses pulse electrochemical deposition and tissue adjustment processes for a nickel plating copper belt. The process comprises the following steps of: performing pulse plating on a nickel coating; performing subsequent cold machining deformation and vacuum heat treatment processes, and the like. By the pulse electrochemical deposition process, the thickness of the nickel coating deposited on the copper belt and the uniformity of a microscopic structure can be effectively ensured; and by the subsequent cold machining deformation and vacuum heat treatment processes, the comprehensive mechanical property, particularly the bending resistance and the physical property of the nickel plating copper belt can be improved, so that high-quality nickel plating copper belts required in industries such as electronics, batteries, electrovacuum, electric light sources and the like can be possibly processed. The pulse nickel plating and tissue adjustment process is low in required equipment investment, has a simple method, is convenient to operate and is suitable for industrial production.

Owner:CHANGSHA STORM ENERGY TTECH

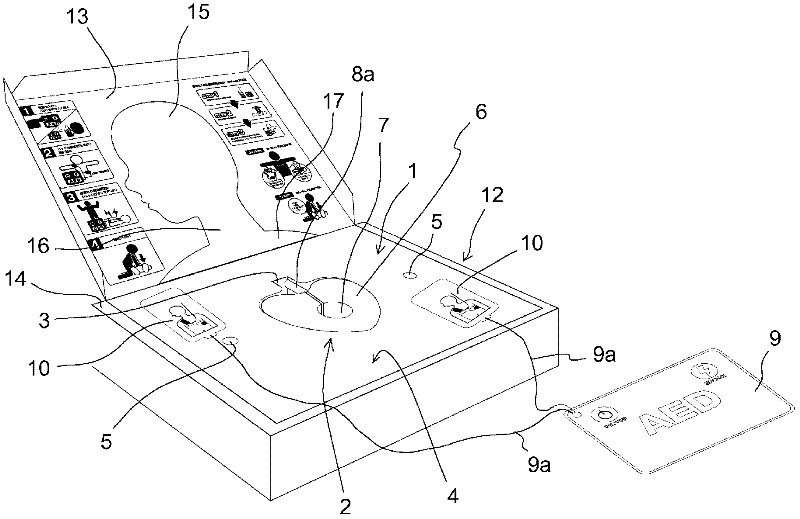

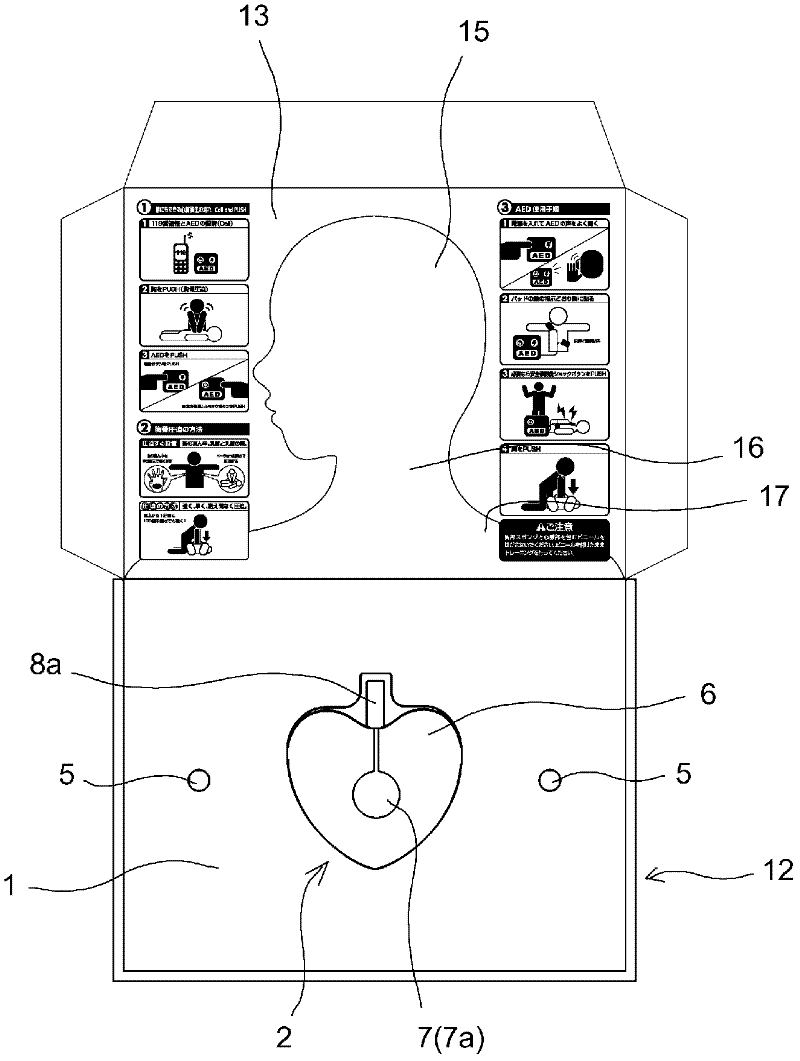

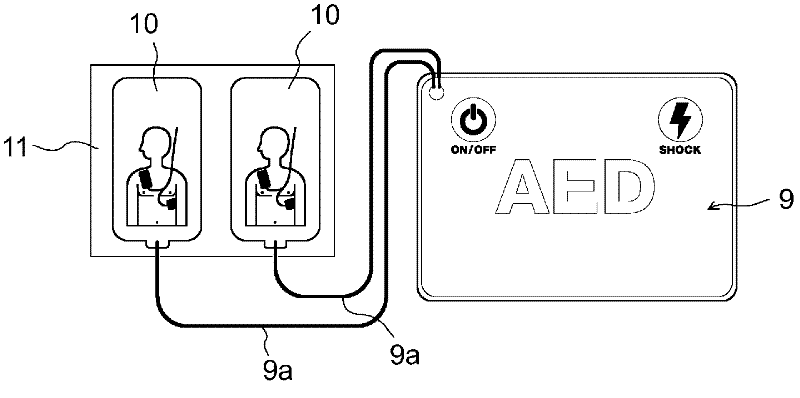

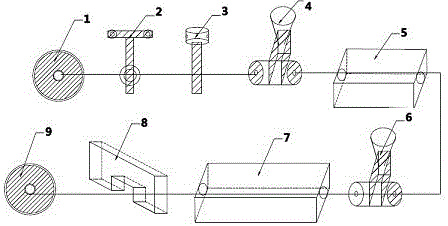

Portable practice tool for heart massaging in cardiopulmonary resuscitation

InactiveCN102460539AEasy to wipe offEasy to replaceCosmonautic condition simulationsEducational modelsHeart massageEmergency medicine

Provided is a training box that is a practice tool for learning heart massaging (sternal compression) through experience; is low-cost, small-sized, light weight, and easy to transport; retains durability under repeated use; and on which AED use procedures can also be drilled. The portable practice tool for heart massaging in cardiopulmonary resuscitation is characterized by being provided with a chest-mockup main unit (1) having a thickness that is thicker than a thickness equivalent to the depth of chest cavity subsidence required during heart massaging (sternal compression), in which a palm-sized opening (3) in the center of the chest-mockup main unit (1) is opened in a vertical direction; a closed-cell synthetic resin foam (6a), which is covered by a bag (6d), contracts and expands in a vertical direction, and has a cavity (7) in the interior, is provided in said opening as a pressing part (6) that is moveable in the vertical direction; and a valve (8), which is for both the entrance and exit of air to the abovementioned cavity (7) and the detection thereof, is disposed on a side of the bag (6d).

Owner:KYOTO UNIV

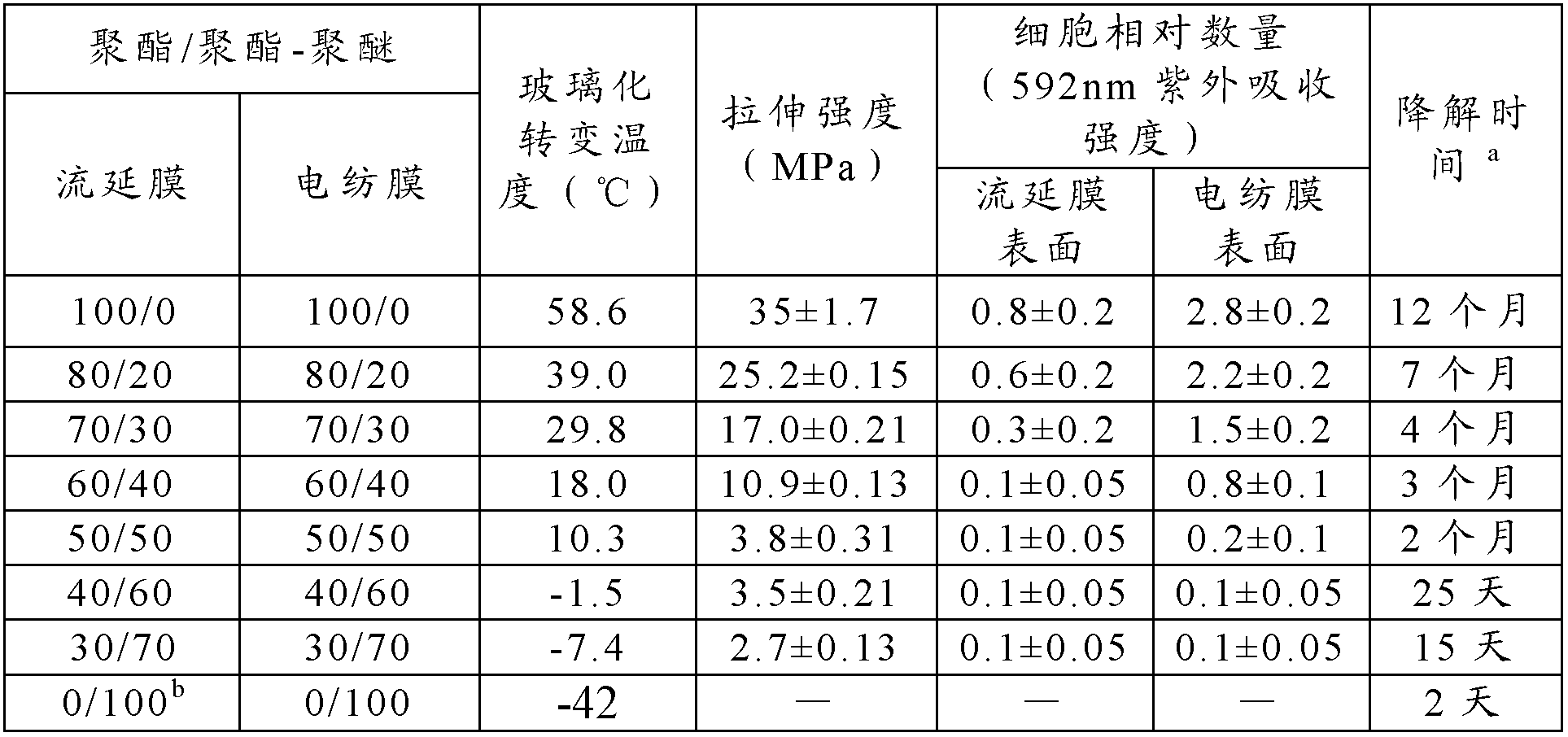

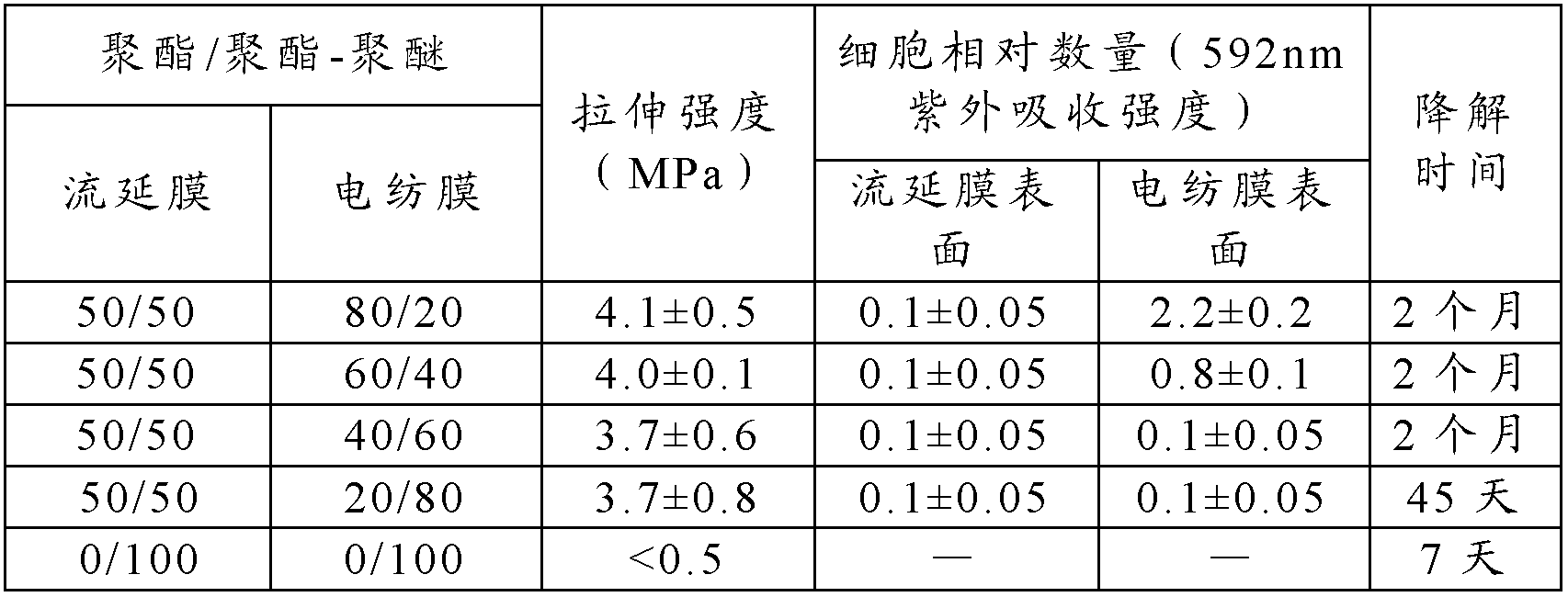

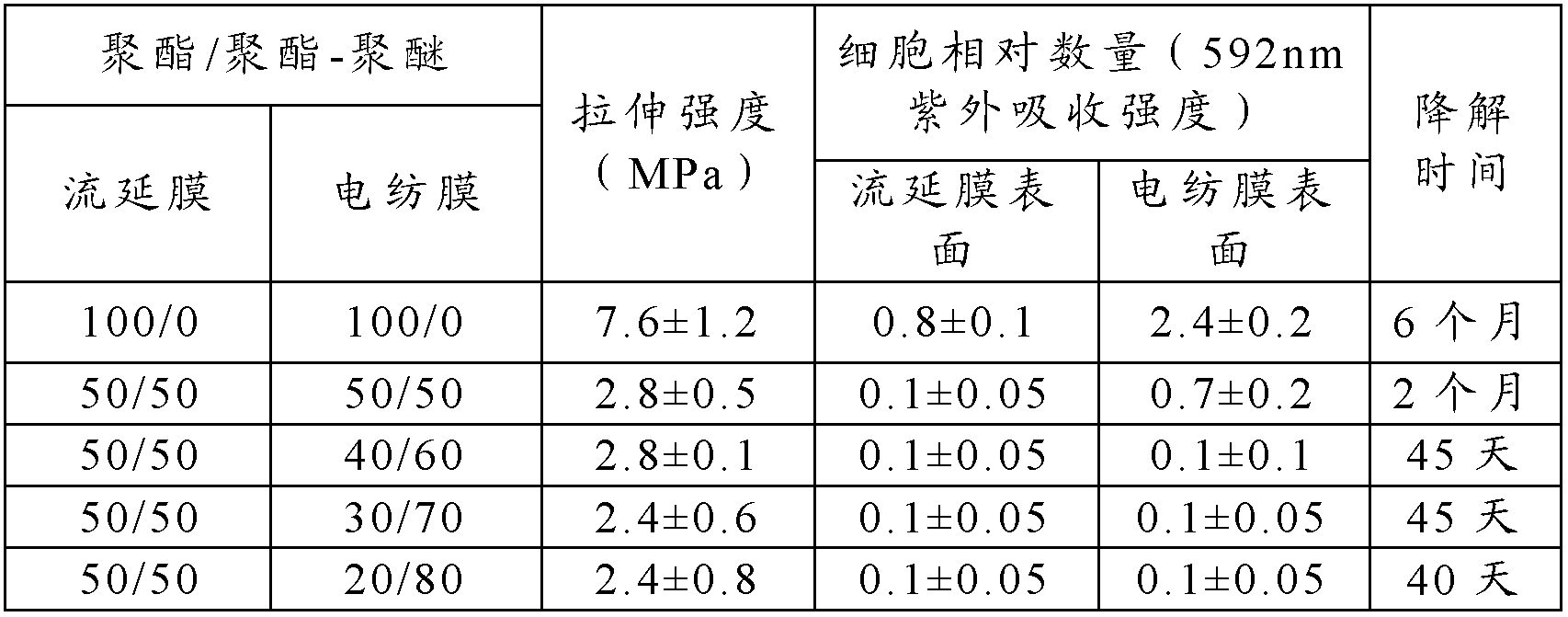

Degradable anti-adhesion compound membrane and preparation method thereof

The invention discloses a degradable anti-adhesion compound membrane which has two layers, wherein one layer of the anti-adhesion compound membrane is a base membrane, and the other layer of the anti-adhesion compound membrane is an electrospinning film; a material of the base membrane and the electrospinning film is a blending material of polyester-polyether copolymer and polymer; and the blending material comprises the following components in percentage by weight, 10%-90% of polyester and 10%-90% of polyester-polyether copolymer. The anti-adhesion compound membrane can be excellently attached to tissues and has a good inhibition effect on fibroblasts, so that the tissues can be effectively isolated and the anti-adhesion effect is achieved. The invention further discloses a preparation method for the anti-adhesion compound film, and the electrospinning membrane of the prepared compound membrane has micro-grade holes and can be effectively attached to the tissues.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

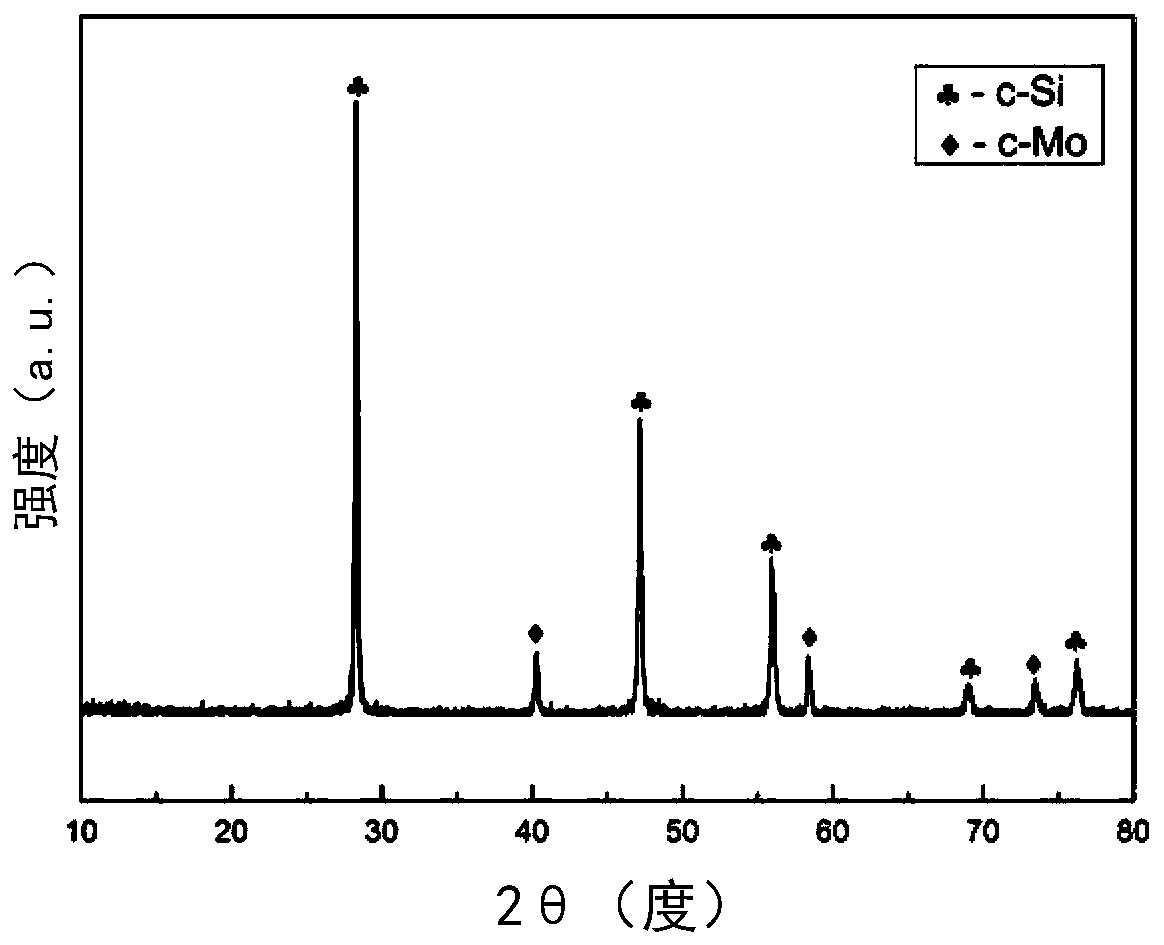

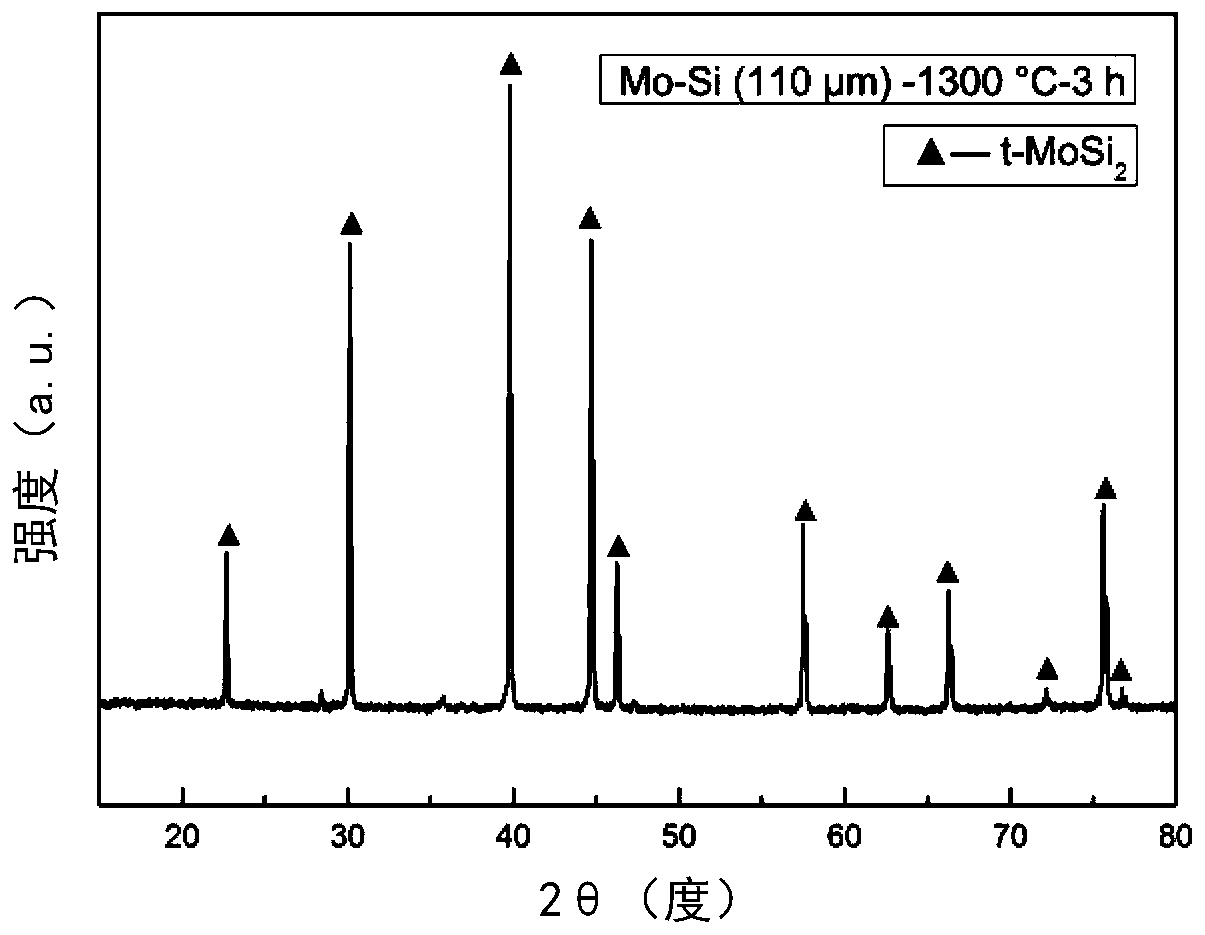

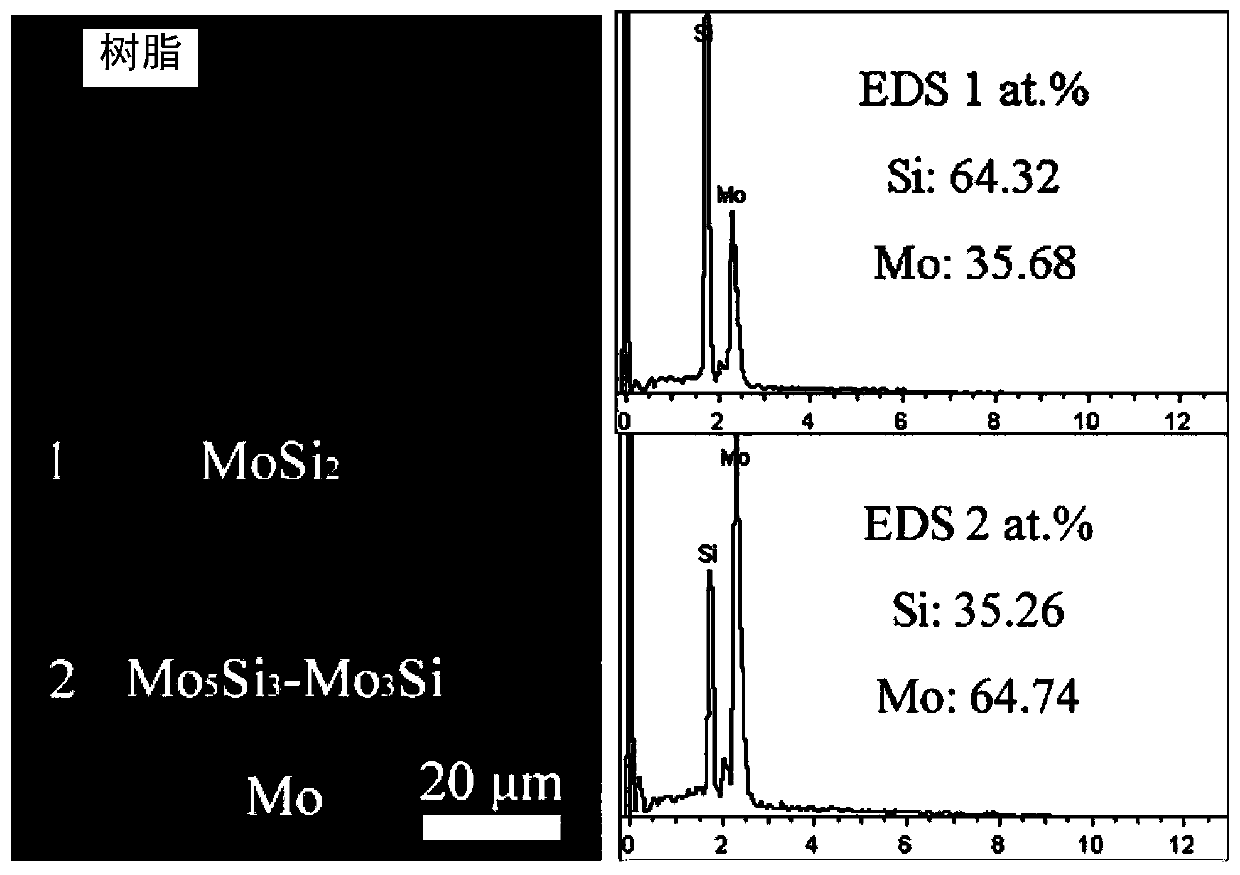

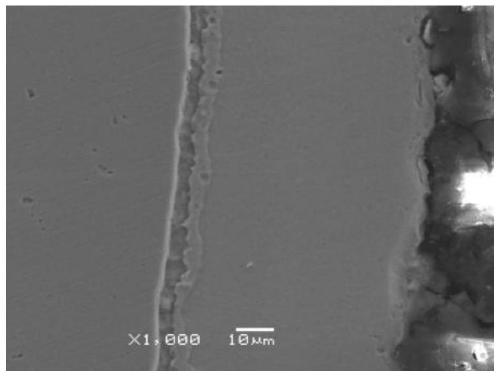

Method for preparing molybdenum silicide coating on surface of molybdenum or molybdenum alloy

ActiveCN107675120ADense thicknessStrong chemical metallurgical bondMolten spray coatingSilica fumeRaw material

The invention relates to a method for preparing a molybdenum silicide coating on the surface of molybdenum or a molybdenum alloy. Silicon powder serves as a raw material, a plasma spraying technologyis adopted to prepare the silicide coating on the surface of the molybdenum or a molybdenum alloy matrix, then, heat treatment is carried out for 1-10 hours under the inert atmosphere at the temperature of 1,000 DEG C-1,500 DEG C, and therefore the molybdenum silicide coating is formed on the surface of the molybdenum or the molybdenum alloy. The preparation method has the advantages that the process is simple, the cost is low, the efficiency is high, repeatability is good, and method is suitable for scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Surface anti-corrosion treatment technology for aluminum fuel tanks

The invention discloses a surface anti-corrosion treatment technology for aluminum fuel tanks. According to the technology, oxide films are formed on the surfaces of the aluminum fuel tanks through the processes of oil removing, polishing, anode oxidizing, closing and roller painting and are compact, appropriately thick and good in compatibility with coatings. The coatings are closely bonded to the surfaces of the fuel tanks, are high in strength and resistant to abrasion and can decorate and protect the outer walls of the fuel tanks well. According to the technical scheme, the technology has the advantages of being high in operability, low in cost and especially suitable for anti-corrosion work of the volume-produced aluminum fuel tanks.

Owner:SHIYAN HENGRONG IND

Housing as well as manufacturing method thereof and electronic device

The invention provides a manufacturing method for a housing. The manufacturing method comprises the following steps of: providing an aluminum base material; performing hard anode oxidization treatment on the aluminum base material, and forming a first aluminum oxide layer on the surface of the aluminum base material, wherein the first aluminum oxide layer is provided with micro pores, and voltage and current in a hard anode oxidization treatment process are automatically regulated through hard anode oxidization treatment; performing dyeing treatment on the aluminum base material; and polishing the dyed aluminum base material to obtain the housing. The housing manufactured by the manufacturing method for the housing provided by the invention has a black and bright appearance and a ceramic texture. The invention further provides the housing manufactured by the manufacturing method for the housing and an electronic device applying the housing.

Owner:徐州宏恩包装新材料有限公司

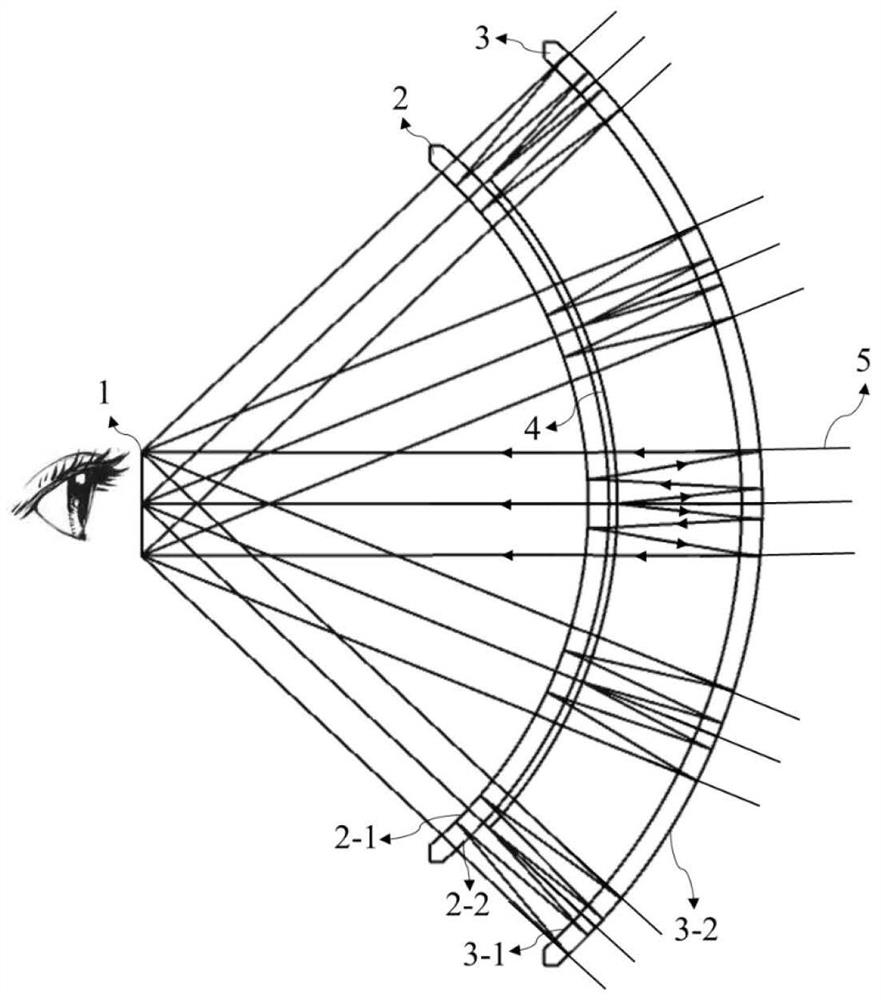

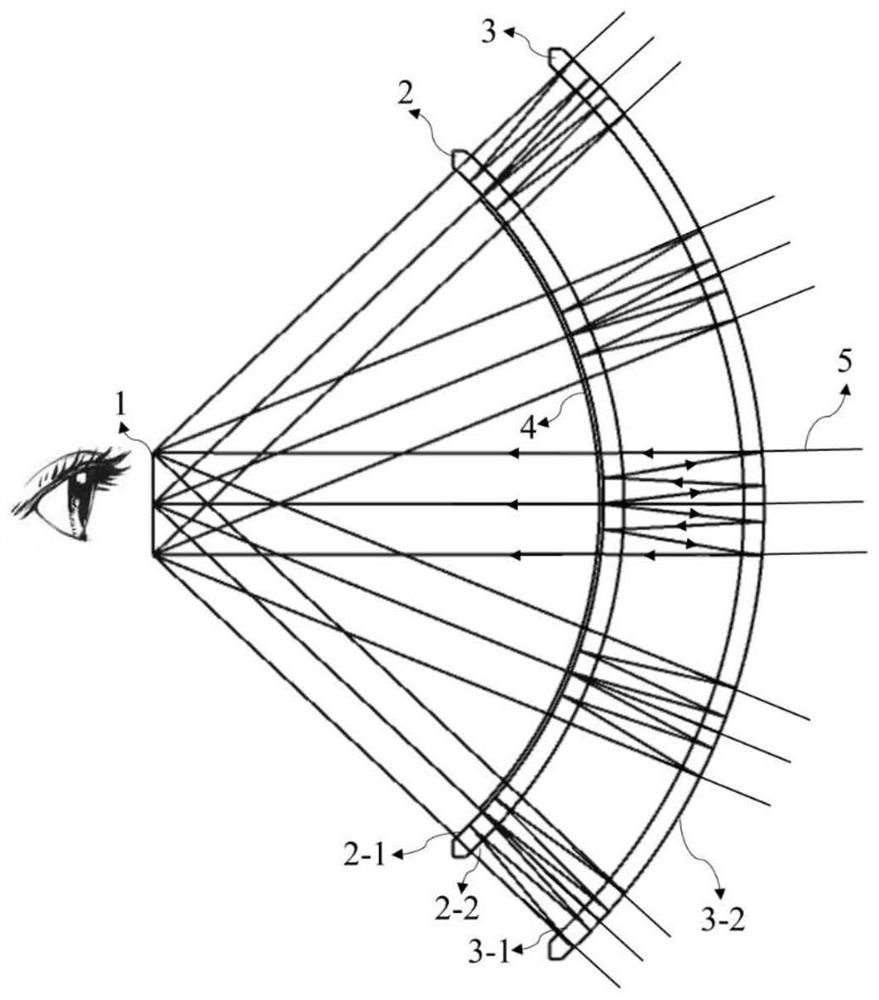

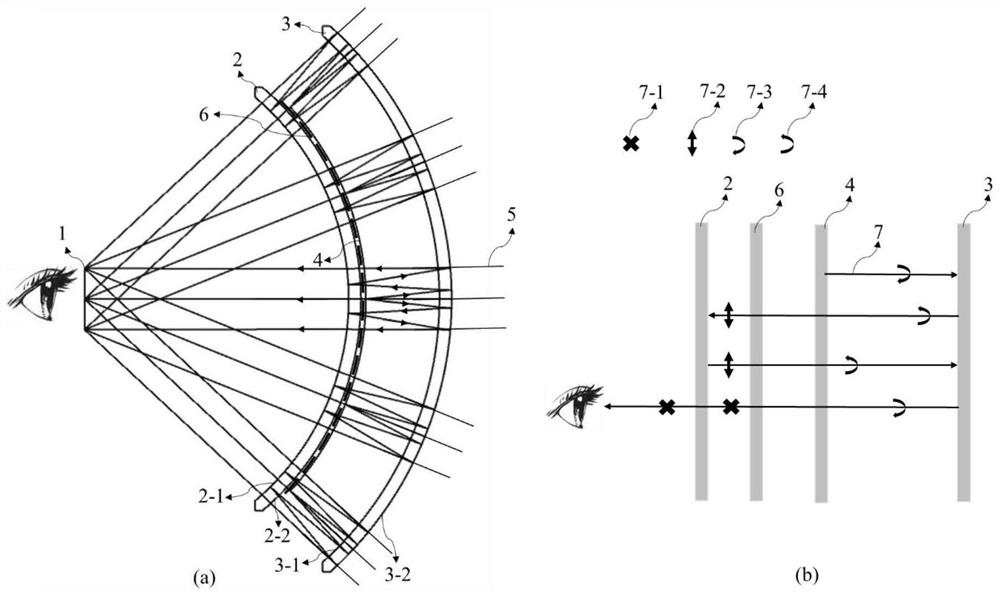

Portable short-focus near-to-eye display system

PendingCN112799232AThe overall thickness is thinDense thicknessOptical elementsSteroscopic systemsDisplay deviceEyewear

The invention provides a portable short-focus near-to-eye display system, relates to the technical field of near-to-eye display, and solves the problem of contradiction between optical performance and volume in the existing AR technology. The system comprises a micro display, an inner side lens and a concave surface partial reflector; the lenses close to the eye pupil position are inner side lenses, and the lenses far away from the eye pupil position are concave surface partial reflectors; the micro display is a rotary linear display or a transparent display. Through multiple reflections, the light path is folded, so that the distance between the convex surface part reflector and the concave surface part reflector is shortened, the thickness of the glasses can be reduced to the maximum extent, and lightness and thinness are realized.

Owner:GUANGGAN SHANGHAI TECH CO LTD

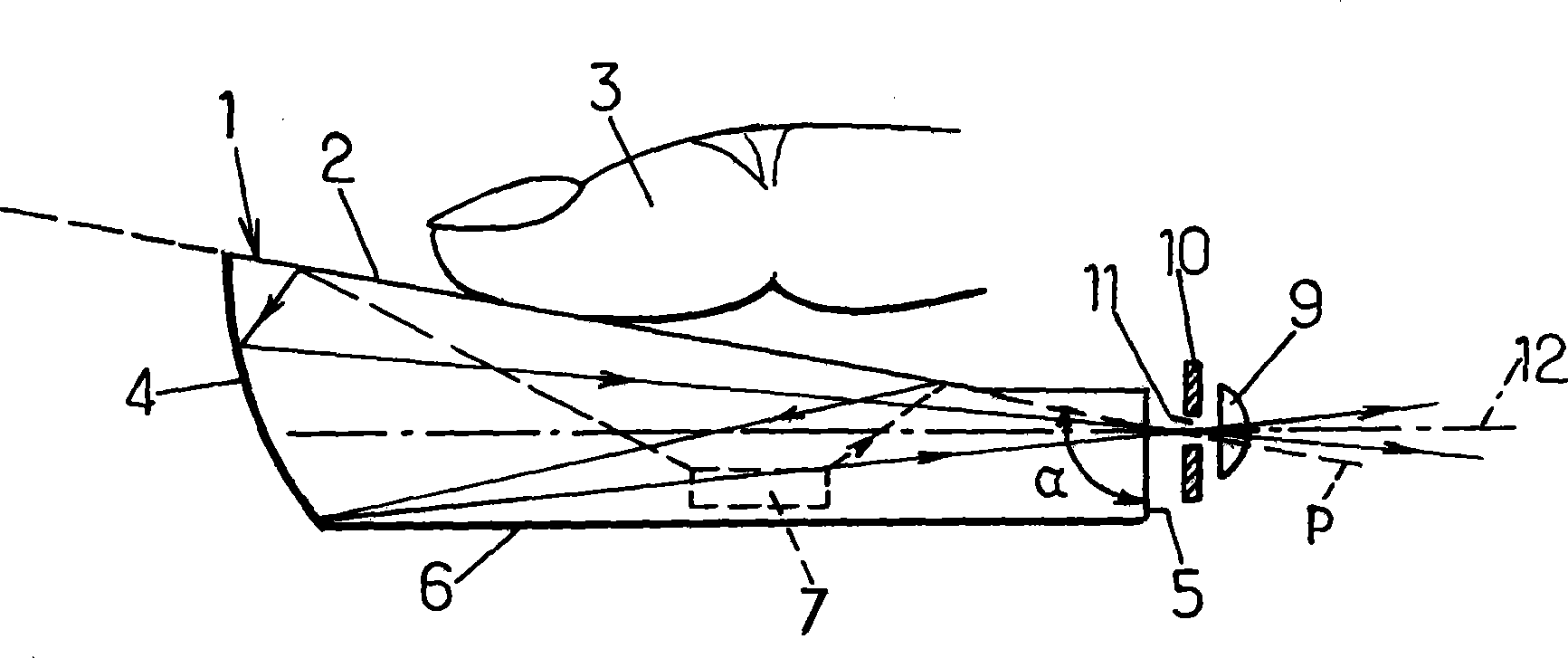

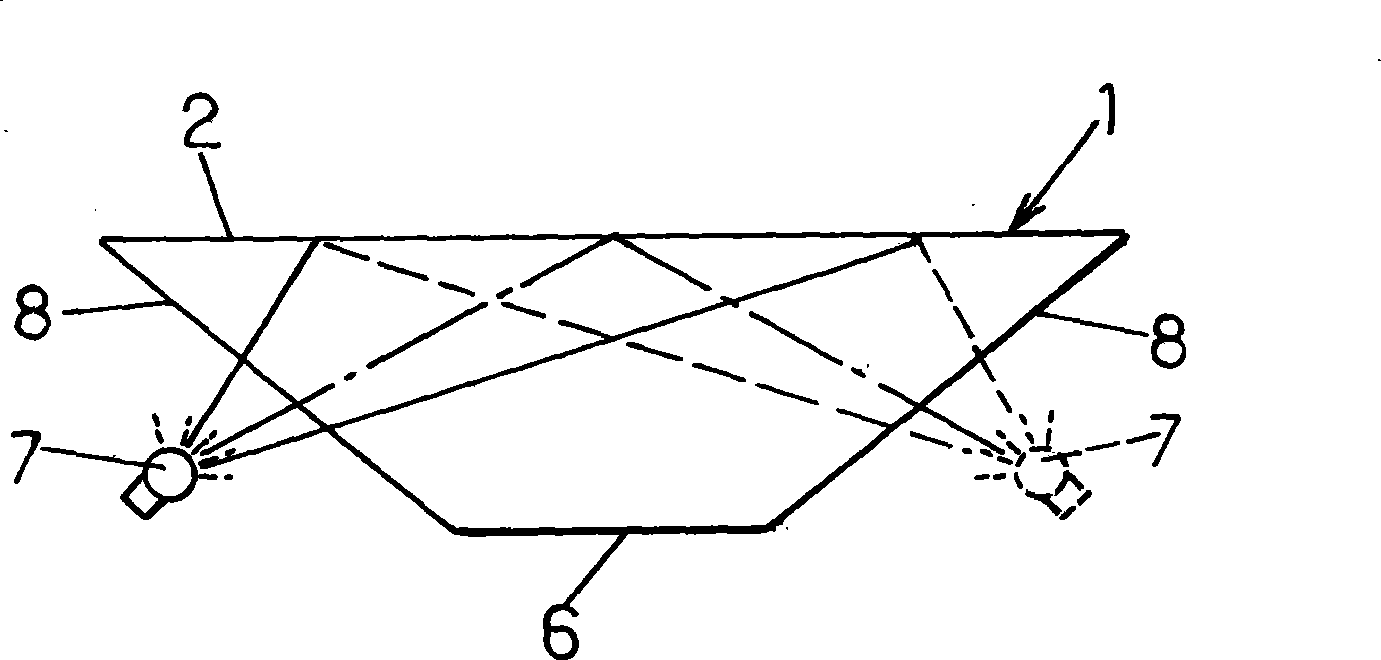

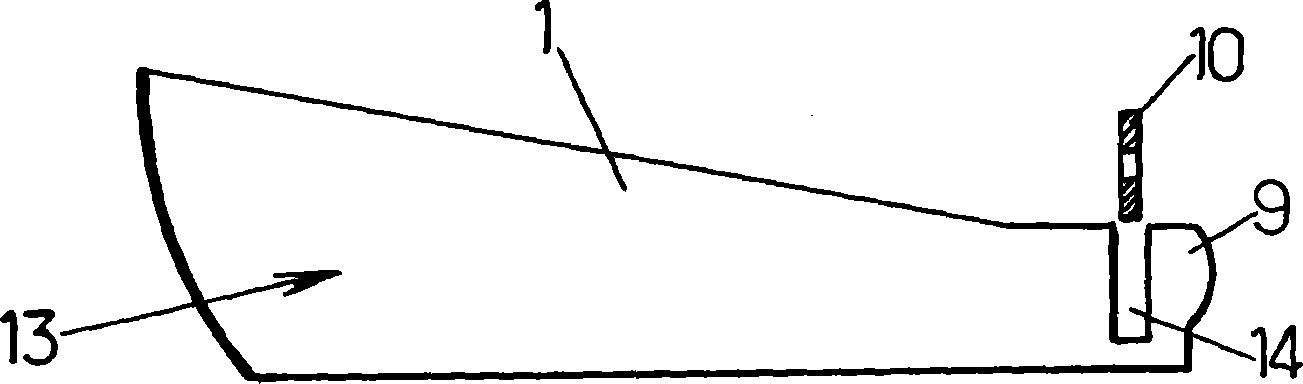

Optical finger print image forming device

InactiveCN1867927AIncreasing the thicknessReduce thicknessPrismsCharacter and pattern recognitionBiomedical engineeringFingerprint image

The invention relates to an optical device which is used to form a fingerprint image. The inventive device comprises an optical plate (1) having a first main face (2) on which a finger (3) is placed, a first side face (4) comprising a converging mirror, and a second side face (5) which is disposed opposite the first side face and which forms an output face, a focusing lens (9) being disposed opposite said output face (5). According to the invention, the first main face (2) forms an angle greater than 90 DEG with the output face (5), such that: the incidence of light rays on the first main face, inside the optical plate, is increased; the stray radiation at the output face is reduced,; and a thinner plate can be used.

Owner:萨热姆安全公司

Composite humidity sensitive material used for capacitive humidity sensor and sensor preparation method

InactiveCN107607594AControllable thicknessThe operation process is simpleMaterial capacitancePolyamidePolytetrafluoroethylene

The present invention provides a composite humidity sensitive material used for a capacitive humidity sensor and a sensor preparation method, the formula of the composite humidity sensitive material is as follows: mixing titanium oxide or barium titanate with barium strontium titanate in the mass ratio of 1:1-1:3 to obtain an initial functional ceramic material, mixing polyamide or polytetrafluoroethylene with the initial functional ceramic material in the mass ratio of 0.3wt%-0.5wt% to obtain a mixture; and mixing an inert metal with the mixture in the mass ratio of 15wt%-25wt%. A composite humidity sensitive film is prepared by an aerosol deposition technology from the composite humidity sensitive material, and the capacitive humidity sensor is prepared from the film by a semiconductor processing technology. The sensor has high precision, high stability, heat resistance, pollution prevention and high reliability.

Owner:王琮

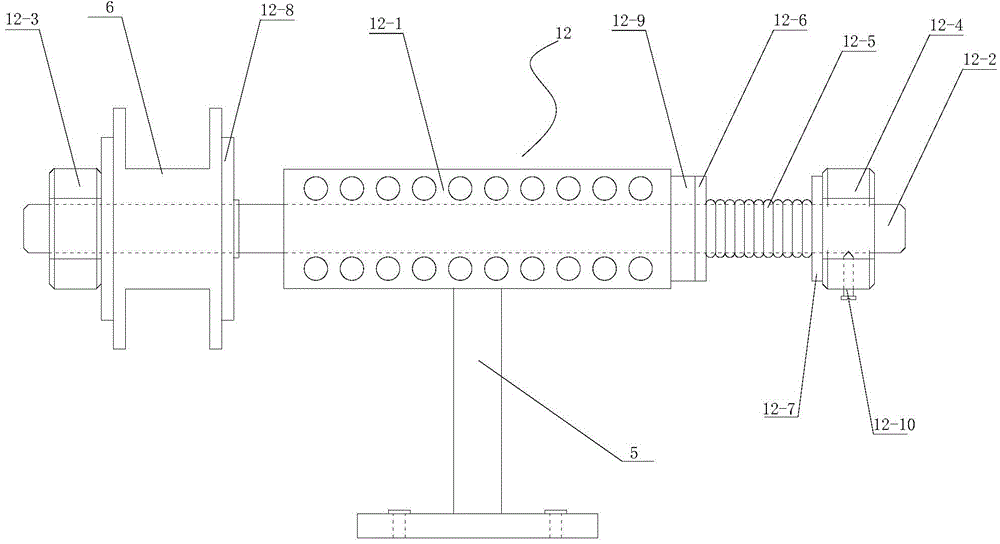

Processing process for plating gold on insoluble metal wire

The invention discloses a processing process for plating gold on an insoluble metal wire. The processing process comprises the following steps: a gold plating device which is provided with a wire release wheel, a plating bath, a heating furnace and a wire winding wheel is adopted, a plating solution inside a plating solution pool flows through a graphite pipe to form circulation so that the plating solution circularly passes through the plating bath, and the insoluble metal wire to be plated, which is wound on the wire release wheel, is wound on the wire winding wheel sequentially from the graphite pipe and the heating furnace; the graphite pipe is connected with the positive electrode of a power supply to form an anode, the insoluble metal wire to be plated is connected with the negative electrode of the power supply to form a cathode, and the graphite pipe and the insoluble metal wire to be plated form a closed circuit through the plating solution; the wire winding wheel rotates to enable the insoluble metal wire to be plated to penetrate through the plating solution at a certain speed to form the insoluble metal wire with a surface plated with gold; and the insoluble metal wire plated with the gold passes through the heating furnace for heating so that a gold plating layer and the insoluble metal wire are closely combined. The processing process disclosed by the invention ensures that the gold plating layer of the insoluble metal wire is uniform and compact in thickness by adopting a continuous gold plating manner, so that the gold plating layer with the high smoothness is obtained.

Owner:CHONGQING MATERIALS RES INST

Production assembly line and production technology of optical unit sheath

The invention discloses a production assembly line and production technology of an optical unit sheath. The production assembly line comprises a paying-off device, a tension controller, a hot melt adhesive coating device, a first extruding machine, a preliminary cooling water tank, a second extruding machine, a complete cooing water tank, an online external diameter monitor and a take-up device which are arranged successively; a stainless steel pipe is coiled on the paying-off device; and the tension controller controls a tension force, the hot melt adhesive coating device coats a surface with an adhesive, the first extruding machine carries out first plastic extrusion of the sheath, the preliminary cooling water tank carries out preliminary cooling, the second extruding machine carries out secondary plastic extrusion of the sheath, the complete cooing water tank carries out complete cooling, the online external diameter monitor detects an external diameter value, and the take-up device carries out rolling. According to the invention, the thickness and external diameters of prepared optical units are uniform, the radial water-blocking performance is high, the stainless steel pipe is combined with the sheath tightly, and the vertical water blocking performance is high.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

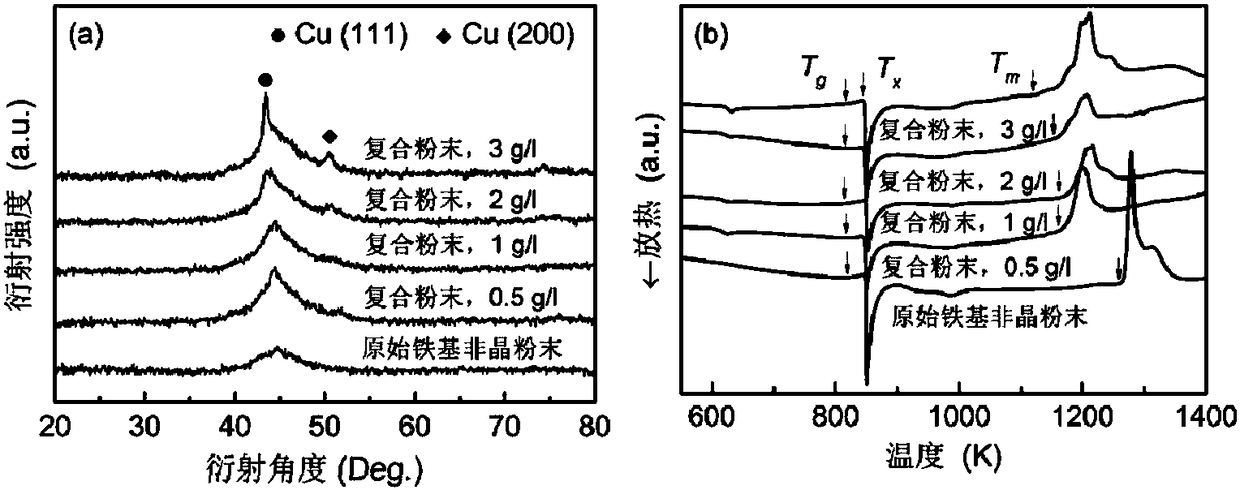

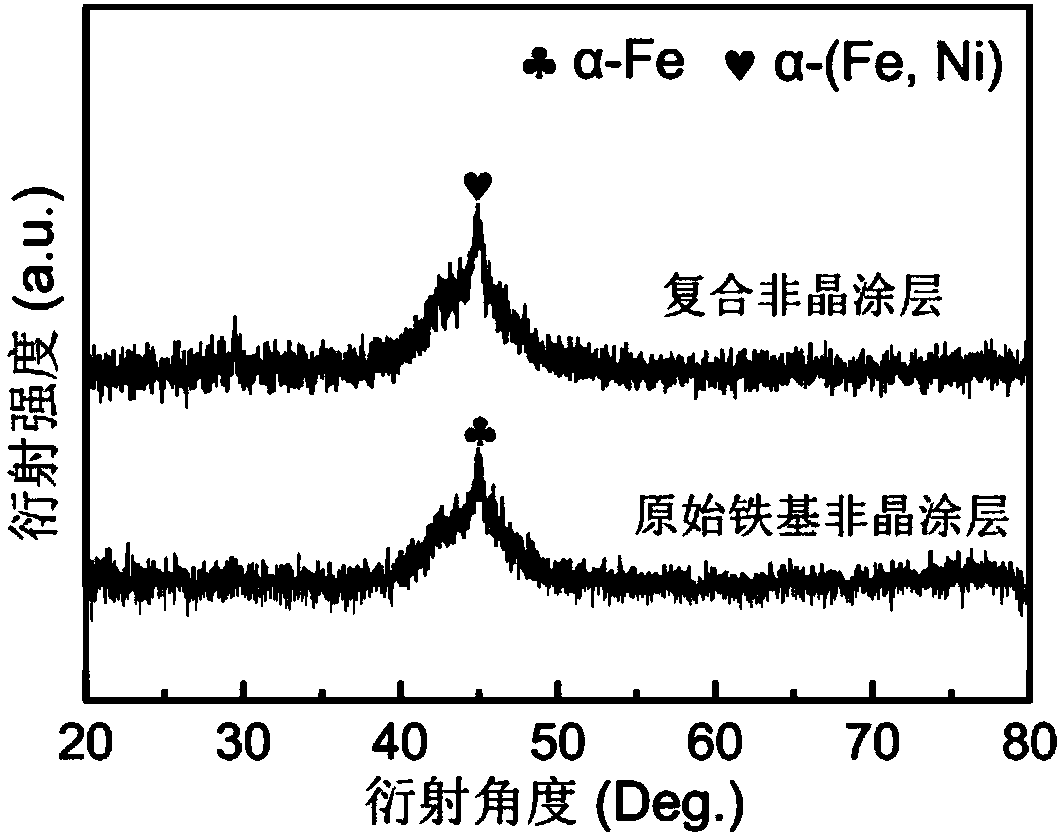

High-conductivity amorphous soft magnetic coating

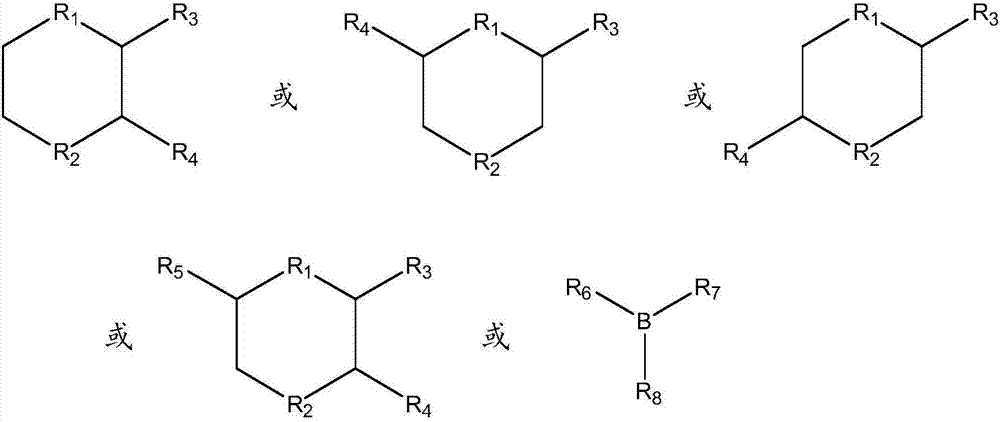

InactiveCN108620576AImprove conductivityUniform thicknessMolten spray coatingTransportation and packagingHigh conductivityIron based

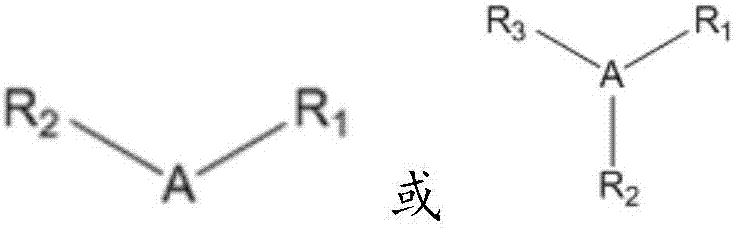

The invention provides a high-conductivity amorphous soft magnetic coating. The high-conductivity amorphous soft magnetic coating comprises conductive magnetic amorphous powder. The conductive magnetic amorphous powder comprises iron-based amorphous magnetic powder and a conductive amorphous layer, wherein the surface of the iron-based amorphous magnetic powder is coated with the conductive amorphous layer, and the iron-based amorphous magnetic powder comprises the components shown by the formula: (Fe0.76Si0.09B0.1P0.05)100-xMx, and in the formula, M is selected from Nb, Co, Ni, Cu, Mo, Cr, Mnand V or the combination of Nb, Co, Ni, Cu, Mo, Cr, Mn and V; x is the atomic ratio, 0<=x<=4, and the atom content of Fe in the iron-based amorphous magnetic powder is over 70%; and the conductive amorphous layer is in an amorphous state. The coating is uniform in thickness and has good compactness and conductivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

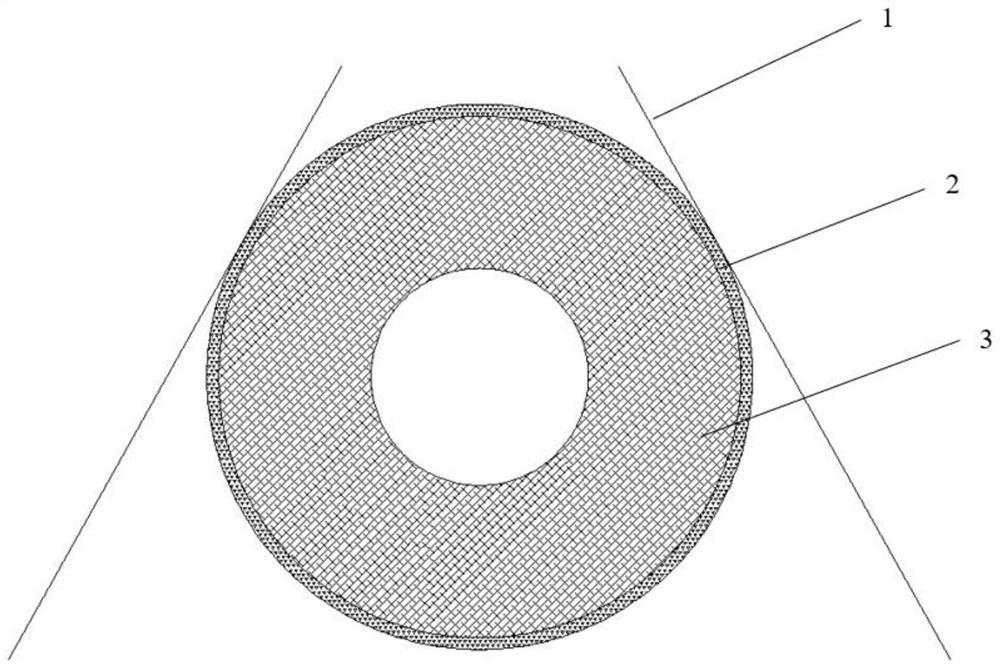

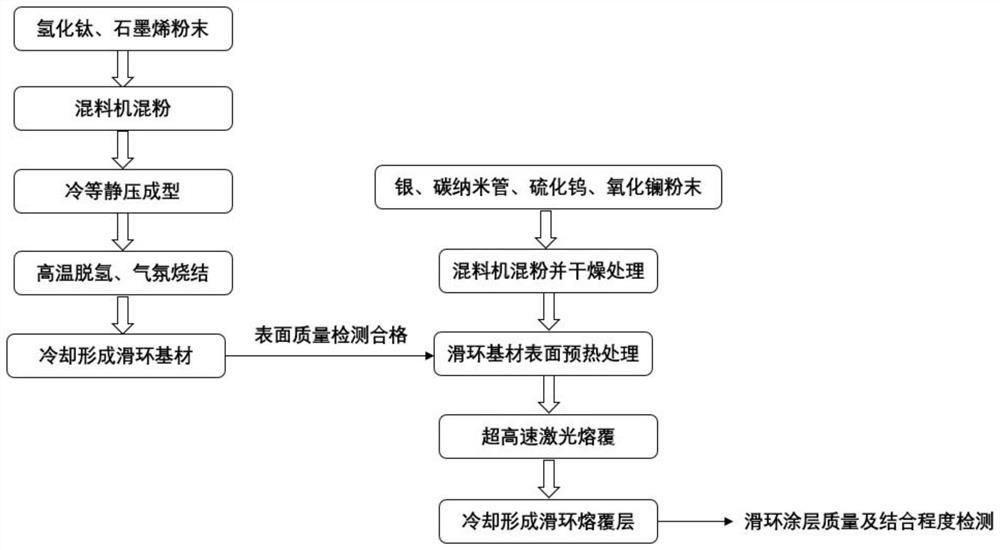

Light high-conductivity slip ring and preparation method thereof

PendingCN114069360AHigh strengthGood heat resistanceRotary current collectorMetallic material coating processesPowder metallurgyCarbon nanotube

The invention discloses a light high-conductivity slip ring and a preparation method. the light high-conductivity slip ring comprises a base material and a coating covering the base material; the base material comprises, by mass, 5-10% of graphene and 90-95% of titanium hydride; and the coating comprises, by mass, 0.5-1.3% of lanthanum oxide, 1-2% of tungsten sulfide and 7-12% of carbon nanotubes, and the balance is silver. The coating is cladded on the surface of the base material made of powder metallurgy through an ultra-high-speed laser cladding technology to form the coating of the slip ring. According to the conductive slip ring, light weight is achieved, the hardness and the arc corrosion resistance of the slip ring coating are enhanced, the antifriction and wear-resistant capacity of the working face of the slip ring is improved, the current-carrying performance is also improved compared with that of pure silver, the process is simple, and the manufacturing cost of the conductive slip ring for spaceflight is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

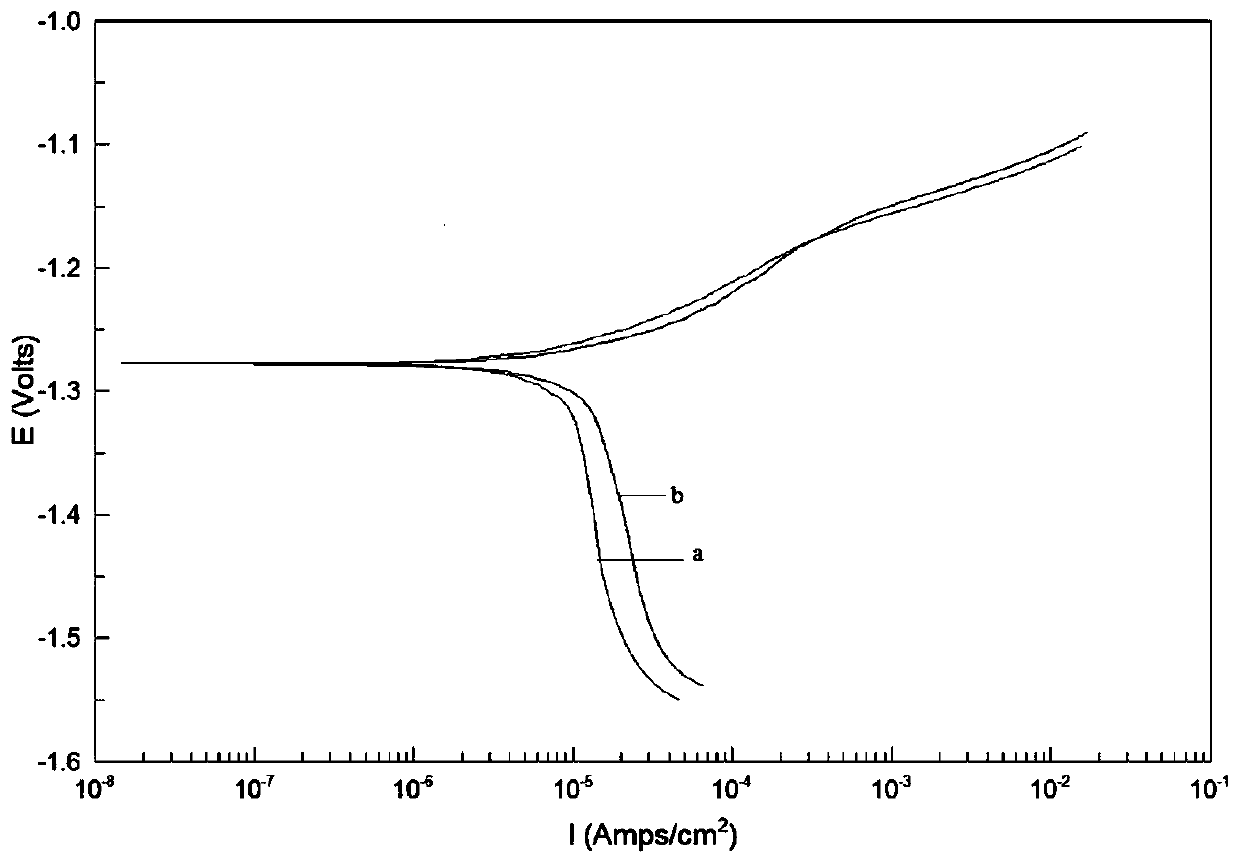

Copper-bearing zinc impregnation agent and method for zinc impregnation of metal material

ActiveCN107164720AIncrease the speed of diffusionReduce crackingSolid state diffusion coatingMetallic materialsHardness

The invention discloses a copper-bearing zinc impregnation agent and a method for zinc impregnation of a metal material. The copper-bearing zinc impregnation agent consists of zinc powder, lanthanum nitrate, ammonium chloride, copper powder and aluminum oxide. The method for the zinc impregnation of the metal material comprises the following steps: after a metal matrix is subjected to oil removal and rust removal treatment, the metal matrix and the copper-bearing zinc impregnation agent are placed in a sealed environment for annealing treatment and cooling. With the adoption of the copper-bearing zinc impregnation agent, the zinc activity can be improved, the zinc impregnation velocity can be raised, the self corrosion potential and the corrosion current density of the metal material can be reduced, and the corrosion resistance and the rigidity of the metal material can be improved.

Owner:XIANGTAN UNIV

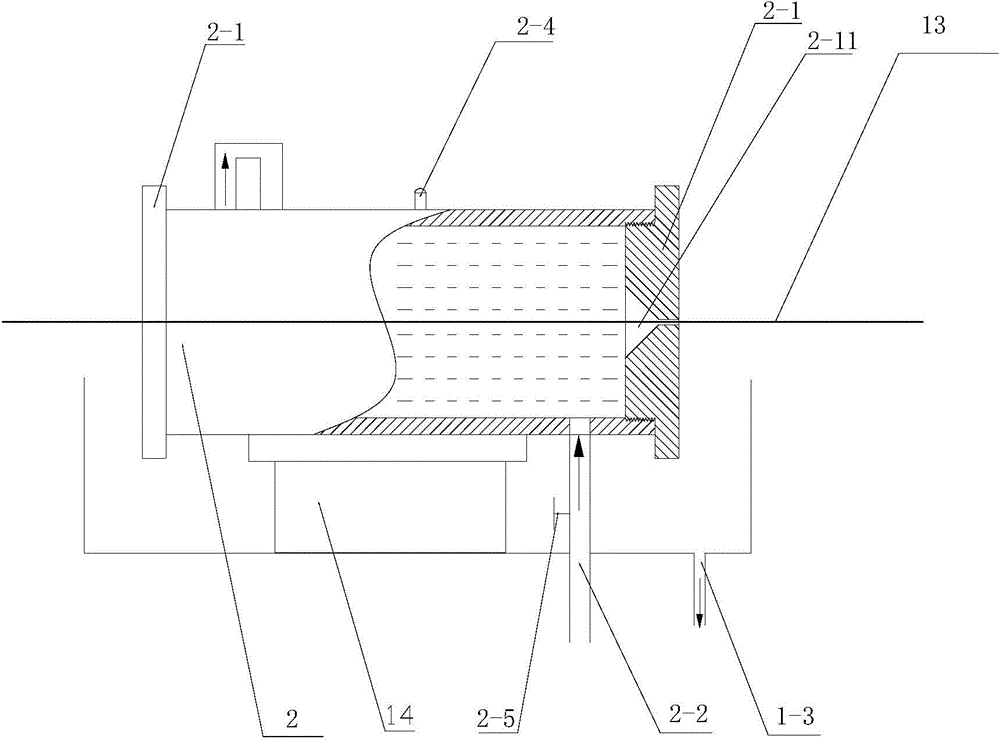

A process method and device for manufacturing polymer ceramic pipeline lining

The present invention separates a process method for manufacturing polymer ceramic pipeline lining, which is mainly composed of 70-90%wt ceramic powder, 5-25%wt polymer material and 0.1-5%wt curing agent raw material, First, mix and stir the above raw materials to form the enamel paint, calculate the amount of enamel paint added according to the length, thickness and specific gravity of the pipeline lining, add the enamel paint to the pipeline that is sealed and supported on the driving wheel, and the motor drives the driving wheel to make the pipeline in Rotate slowly and then quickly at 100 to 1000 rpm. During the rotation, the enamel paint is coated, formed and cured. The lining of the present invention not only has good strength, high hardness, high temperature resistance and corrosion resistance, but also has a uniform thickness. , dense, smooth and wear-resistant, long service life. At the same time, the device is compact and simple in structure, easy to operate, high in enamelling efficiency, and can realize large-scale production. Urban pipe lining processing.

Owner:袁茂豪

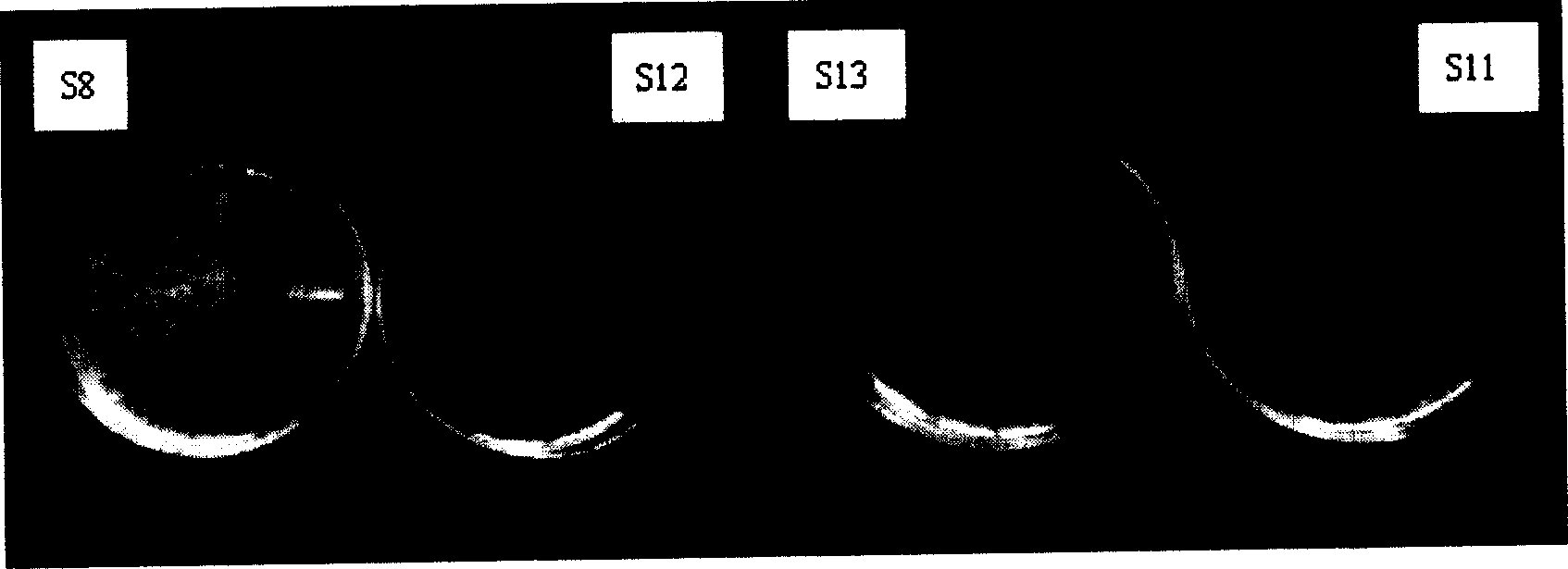

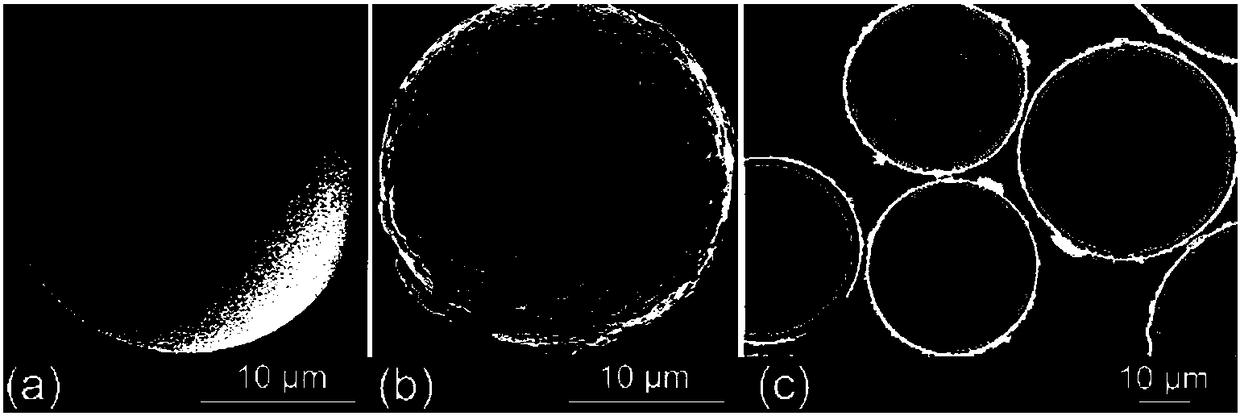

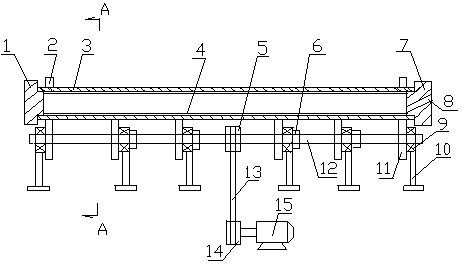

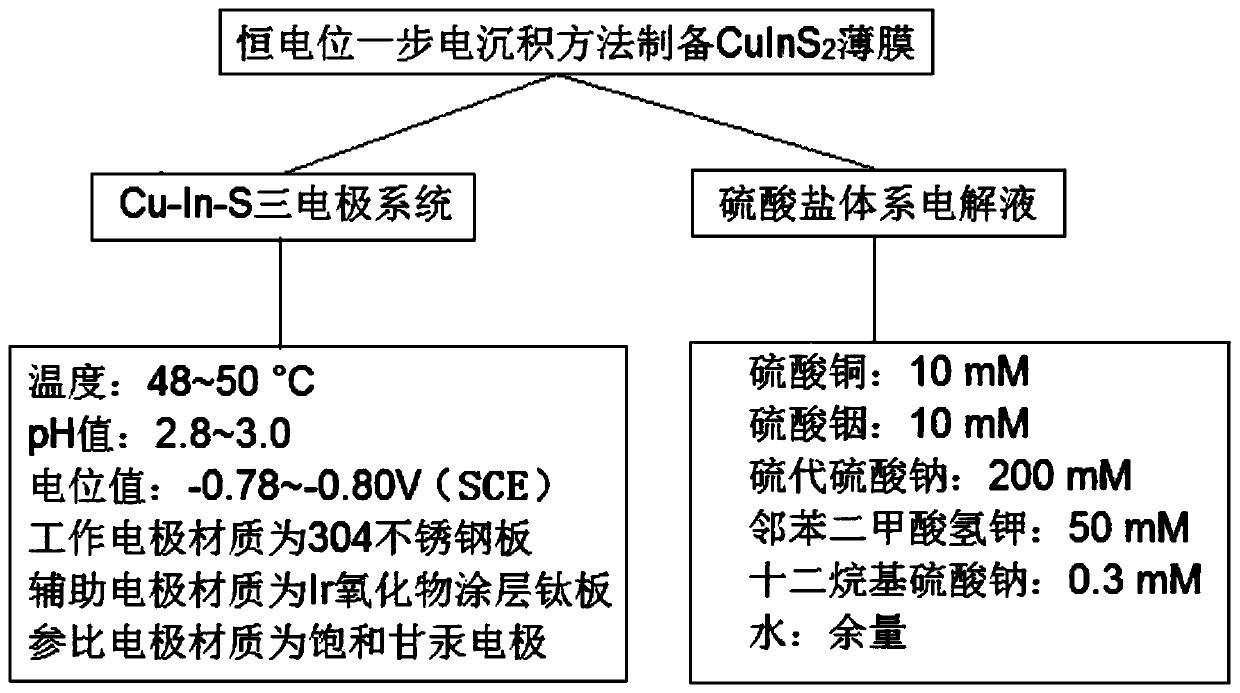

CuInS2 thin film and preparation process thereof

InactiveCN111485266APromote crystallization refinementDense pollutionElectrolytic inorganic material coatingElectrolytic agentIndium

The invention provides a CuInS2 thin film and a preparation process thereof, and relates to the technical field of thin film materials. The stoichiometric ratio of each component of the thin film is close to an ideal stoichiometric ratio; the thin film is flat in appearance, uniform in thickness and compact in tissue; and a forbidden bandwidth of the thin film is close to the optimal forbidden bandwidth of an ideal solar cell photoelectric material; the stoichiometric ratio of the components of the film is Cu: In: S (at%) = 1: 1.082: 1.965; the grain size is 0.4 to 1.3 micros; the forbidden bandwidth Eg is 1.459 eV; a constant-potential one-step electro-deposition method is adopted for preparation, and a Cu-In-S three-electrode system and sulfate system electrolyte are adopted during electro-deposition; and the electrolyte comprises copper sulfate, indium sulfate, sodium thiosulfate, potassium hydrogen phthalate, lauryl sodium sulfate and water. The technical scheme is suitable for thepreparation process of the CuInS2 thin film.

Owner:UNIV OF SCI & TECH BEIJING

Housing and manufacturing method thereof, electronic device

Owner:徐州宏恩包装新材料有限公司

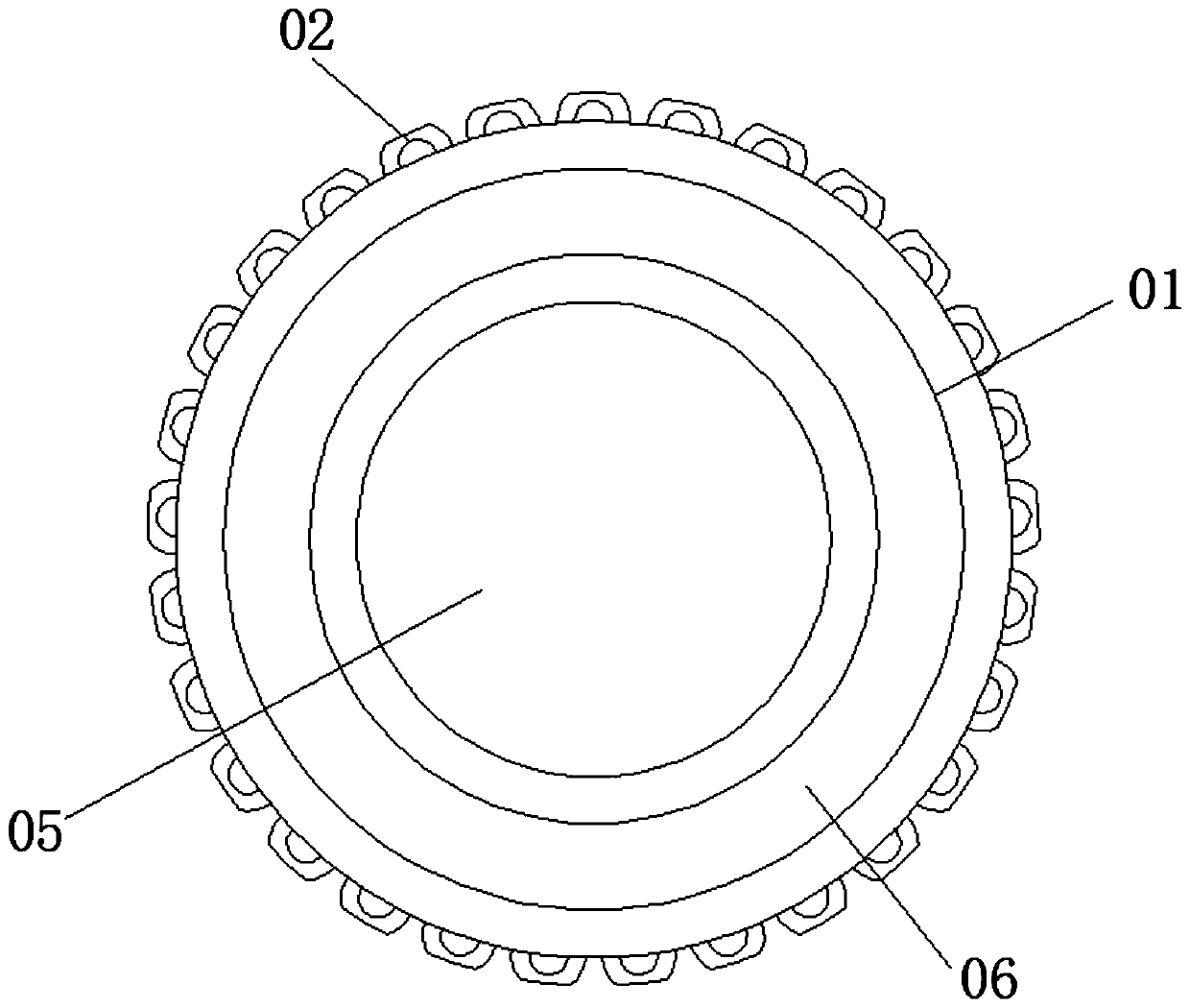

Coiled core pipe with uniform and rough surface

The invention discloses a coiled core pipe with a uniform and rough surface. The coiled core pipe comprises a rotating cylinder, wherein a circular through hole is formed in the inner side of the rotating cylinder; a rotating sleeve is fixedly connected to the circular through hole of the rotating cylinder, and a circular through hole is formed in the outer side of the rotating sleeve; a connecting shaft is fixedly connected to the circular through hole of the rotating sleeve, and the length of the connecting shaft is greater than that of the rotating cylinder; and spraying particles are sprayed on the outer side of the rotating cylinder. According to the coiled core pipe with the uniform and rough surface, by arranging the spraying particles, when a copper aluminum foil is rotated, heading and priming can be well performed on the copper aluminum foil; when the rotating cylinder rotates the copper aluminum foil, the spraying particles are capable of straightening out an uneven surfaceof the copper aluminum foil, so that the phenomenon of wrinkling when the copper aluminum foil is rotated is avoided; and moreover, the spraying particles can be selected according to different thicknesses of the copper aluminum foils, so that friction force between the copper aluminum foil and the rotating cylinder is increased when the copper aluminum foil is rotated.

Owner:SUZHOU TIANYU PLASTIC

Processing Technology of Refractory Metal Wire Gold Plating

Owner:CHONGQING MATERIALS RES INST

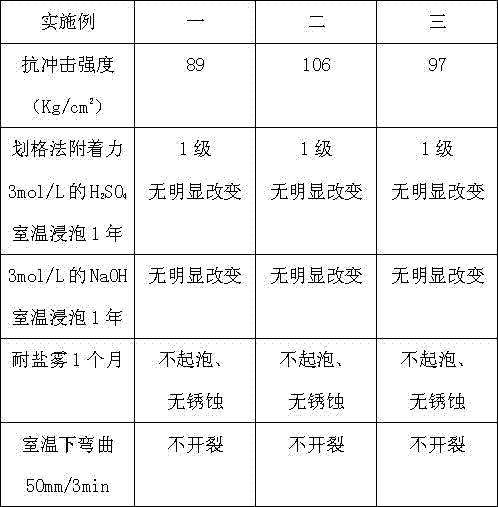

Process method for automobile bottom plate powder coating

InactiveCN107418386AEasy to operateImprove protectionPretreated surfacesAnti-corrosive paintsMelt extrusionElectric field

The invention discloses a process method for automobile bottom plate powder coating. The process method comprises the following steps: preparing raw materials, uniformly mixing the raw materials, performing melting extrusion by using a double-screw extruder, and finally crushing and grinding so as to obtain a powder coating; performing sand blasting roughening on an automobile bottom plate, performing ejection degreasing cleaning, performing hot water cleaning treatment, and performing drying treatment; preheating the pretreated automobile bottom plate, and performing powder coating operation on the surface of the preheated automobile bottom plate by using an electrostatic spray gun in an electric field environment; and performing high-temperature curing on the coated automobile bottom plate, cooling, performing quality inspection, and packaging after qualification, thereby obtaining a coated automobile bottom plate. The process method disclosed by the invention is simple to operate, mild in curing condition and short in curing time, and an obtained coating film has good properties of corrosion resistance, rusting resistance, collision prevention, noise prevention, wearing resistance, impact resistance and the like, is high in strength, good in dispersibility and good in adhesion property, plays a good protection role on an automobile bottom plate, is capable of effectively prolonging the service life of the automobile bottom plate, and is worthy of popularization.

Owner:ANHUI TIANYU AUTO PARTS MFG

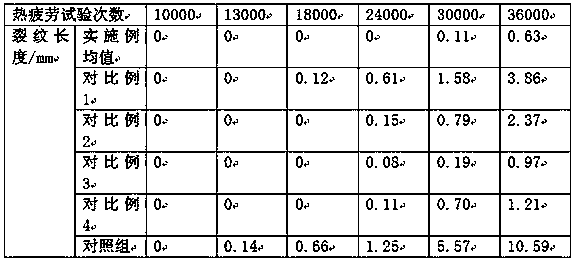

Anti-fatigue vehicle gear processing technology

InactiveCN109022724ASurface treatment process optimizationImprove organizational structureSolid state diffusion coatingFurnace typesSurface layerGear wheel

The invention discloses an anti-fatigue vehicle gear processing technology, and relates to the technical field of gears. The anti-fatigue vehicle gear processing technology comprises the following steps that (1), cleaning is conducted; (2) solid solution modification processing is conducted; and (3) temper modification processing is conducted. The anti-fatigue vehicle gear processing technology isresearched by a plurality of experiments. The vehicle gear surface processing technology is greatly optimized. The vehicle gear organization structure can be effectively improved. The surface layer can be strengthened. Vehicle gear surface layer components, organization and performance are significantly improved.

Owner:含山县林头宝兴铸造厂

A kind of copper-containing zincizing agent and method for zincizing metal material

ActiveCN107164720BIncrease the speed of diffusionReduce crackingSolid state diffusion coatingMetallic materialsHardness

The invention discloses a copper-bearing zinc impregnation agent and a method for zinc impregnation of a metal material. The copper-bearing zinc impregnation agent consists of zinc powder, lanthanum nitrate, ammonium chloride, copper powder and aluminum oxide. The method for the zinc impregnation of the metal material comprises the following steps: after a metal matrix is subjected to oil removal and rust removal treatment, the metal matrix and the copper-bearing zinc impregnation agent are placed in a sealed environment for annealing treatment and cooling. With the adoption of the copper-bearing zinc impregnation agent, the zinc activity can be improved, the zinc impregnation velocity can be raised, the self corrosion potential and the corrosion current density of the metal material can be reduced, and the corrosion resistance and the rigidity of the metal material can be improved.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com