Composite humidity sensitive material used for capacitive humidity sensor and sensor preparation method

A humidity sensor and humidity-sensitive material technology, applied in the direction of material capacitance, etc., can solve the problems of long time required, cumbersome preparation methods, low synthesis temperature, etc., and achieve the effects of stable structure and performance, easy long-term storage, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

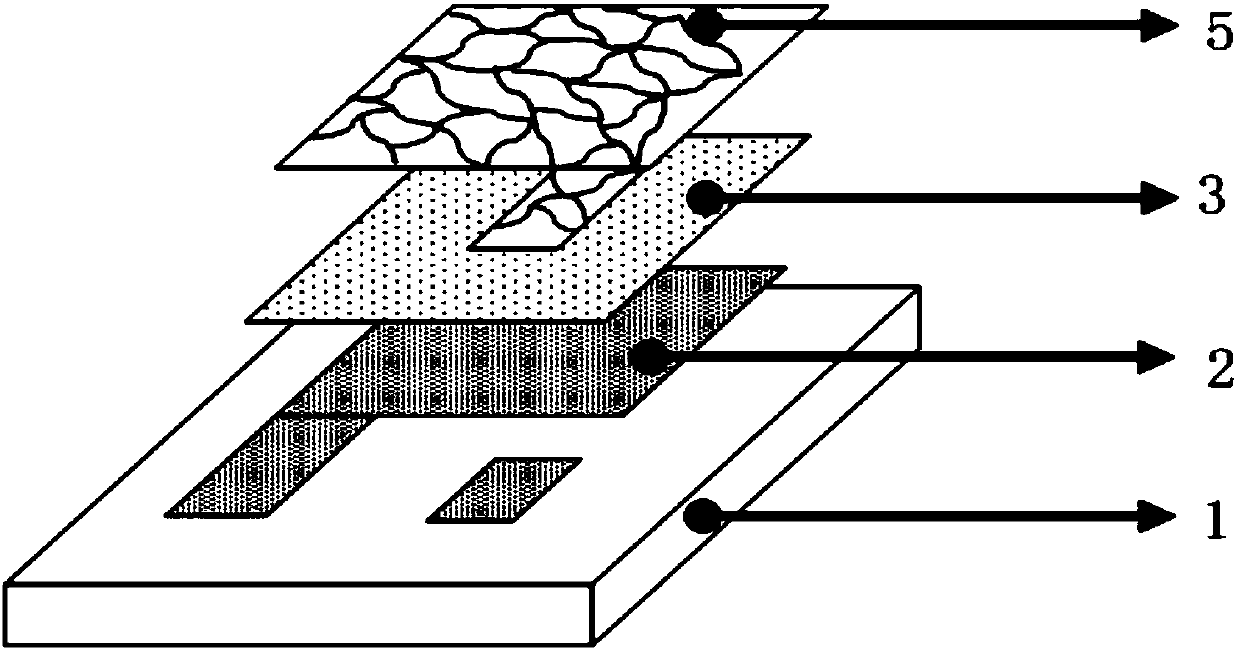

[0039] A method for manufacturing an adjustable capacitive humidity sensor is as follows:

[0040] Step 1. Use a glass substrate and clean it once with isopropylamine solution, and then wash it twice with deionized water to ensure that the surface is clean and free of impurities;

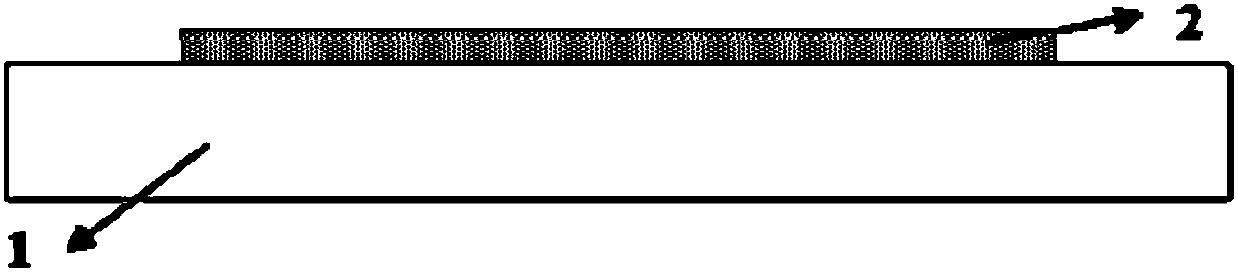

[0041] Step 2, growing a layer of titanium, platinum, gold or chromium with a thickness of about 300-500 nanometers as the lower metal layer of the humidity sensor by means of electron beam evaporation;

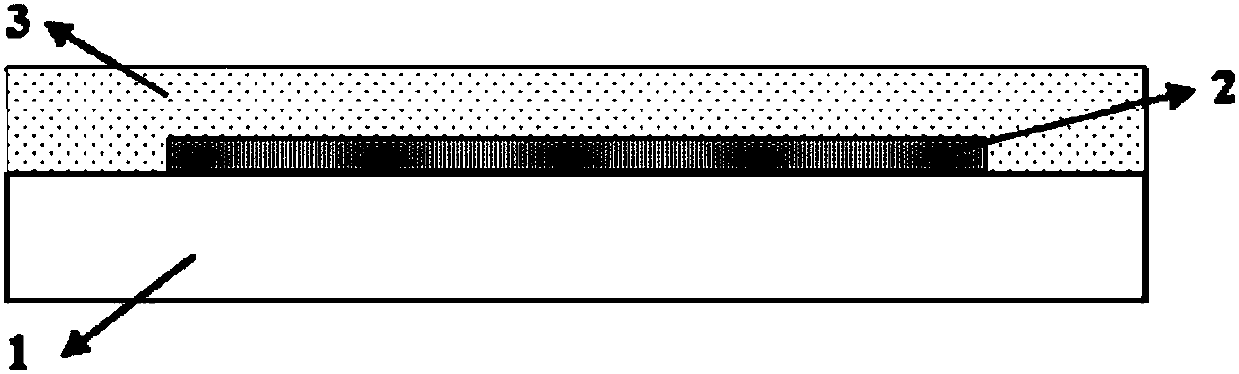

[0042] Step 3. Mix titanium oxide and barium strontium titanate in a mass ratio of 1:1 to form a functional ceramic material by ball milling process, and ensure uniform mixing, so as to obtain higher high-humidity characteristics;

[0043] Step 4. The polyamide (Polyamide) and the above-mentioned functional ceramic material are further fully and uniformly mixed by ball milling method according to the mass ratio of 0.3wt%, so as to obtain the best hysteresis characteristics, which includes both low ...

Embodiment 2

[0052] A method for manufacturing an adjustable capacitive humidity sensor is as follows:

[0053] Step 1. Use a quartz substrate, and use isopropylamine solution to clean it once, and then use deionized water to wash it twice to ensure that the surface is clean and free of impurities;

[0054] Step 2: growing a layer of titanium, platinum, gold or chromium with a thickness of about 300-500 nanometers as the lower metal layer of the humidity sensor by means of electron beam evaporation;

[0055] Step 3: Mix titanium oxide and barium strontium titanate at a mass ratio of 1:1 by ball milling to ensure uniform mixing and stable performance of the initial functional ceramic material, thereby obtaining higher high-humidity characteristics;

[0056] Step 4: The high molecular polymer polyamide (Polyamide) and the above-mentioned functional ceramic material are further fully and uniformly mixed with the functional ceramic material by ball milling method according to the mass ratio of...

Embodiment 3

[0064] A method for manufacturing an adjustable capacitive humidity sensor is as follows:

[0065] Step 1: Use a silicon substrate, wash it once with isopropylamine solution, and then wash it twice with deionized water solution to ensure that the surface is clean and free of impurities;

[0066] Step 2: growing a layer of titanium, platinum, gold or chromium with a thickness of about 300-500 nanometers as the lower metal layer of the humidity sensor by means of electron beam evaporation;

[0067] Step 3: Mix titanium oxide and barium strontium titanate at a mass ratio of 1:1 by ball milling to ensure uniform mixing and stable performance of the initial functional ceramic material, thereby obtaining higher high-humidity characteristics;

[0068] Step 4: The high molecular polymer polytetrafluoroethylene (PTFE) and the above-mentioned functional ceramic material are further fully and uniformly mixed with the functional ceramic material by a ball milling method according to a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com