Gel diaphragm for new rare-earth power supply and preparation method thereof

A technology of gel and diaphragm, applied in the field of gel diaphragm for rare earth new power supply and its preparation, can solve the problems of unbalanced electrochemical reaction, poor concentration of liquid electrolyte, low liquid electrolyte, etc., and achieve stable product performance and thickness. Carbonization resistance and thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

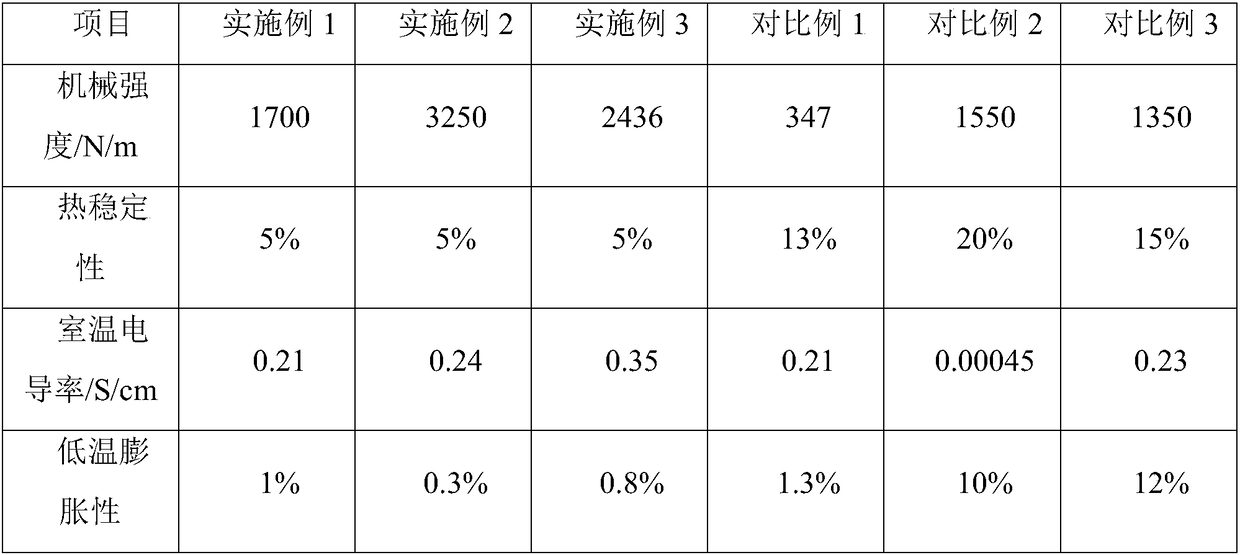

Embodiment 1

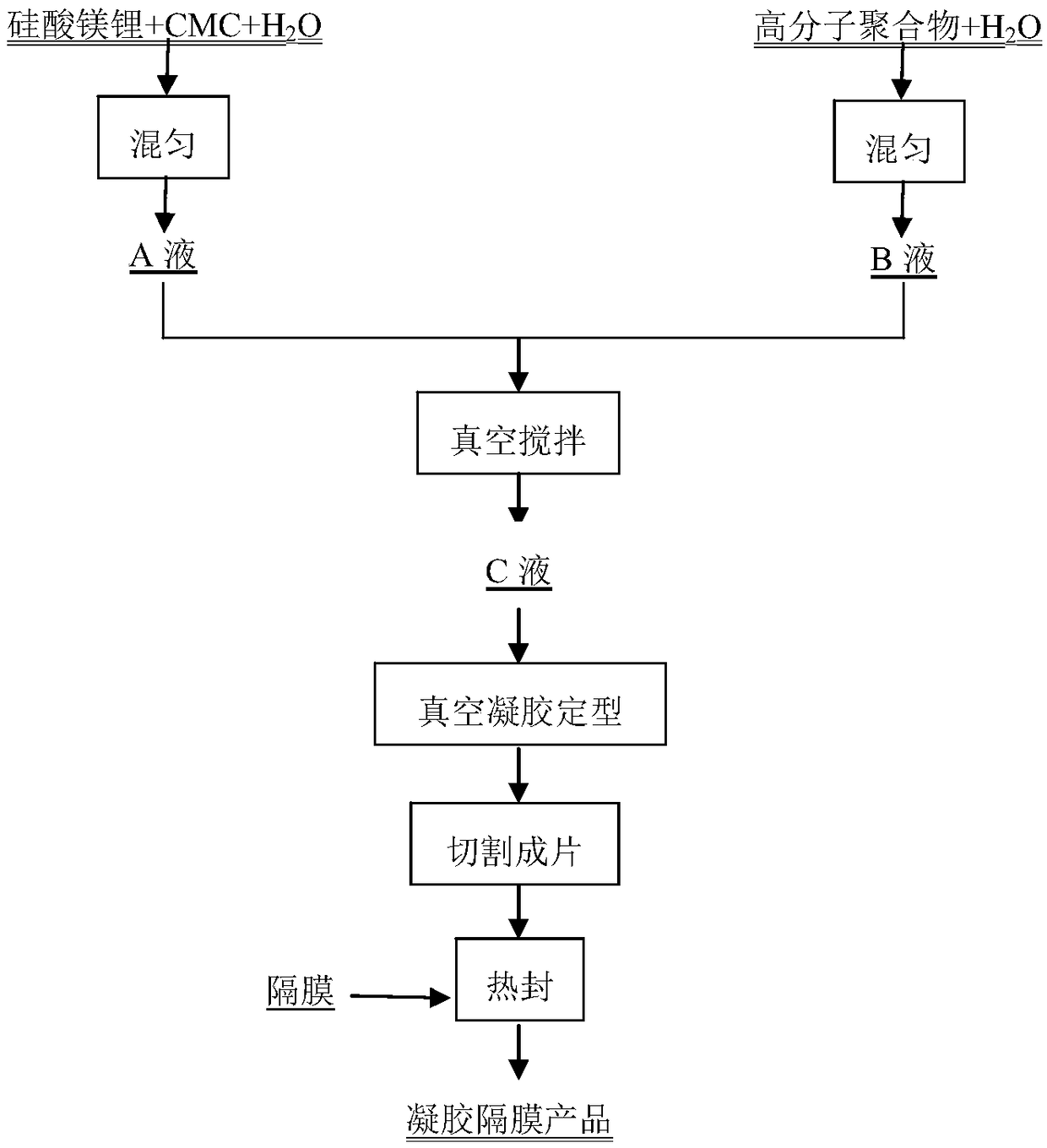

[0035] The preparation method of the gel diaphragm for new rare earth power supply comprises the following steps:

[0036] (1) The inorganic electrolyte magnesium lithium silicate, CMC and H 2O, configured according to the mass ratio of 5:3:92, labeled as liquid A; mix the high molecular polymer PPA and PAAK, the mass ratio is 1:1, the mixed high molecular polymer and H 2 O is configured according to the mass ratio of 5:95, marked as liquid B;

[0037] (2) According to the mass ratio of liquid A and liquid B of 1:1, add liquid A to liquid B and stir evenly to form liquid C; assemble the detachable movable plate into a cuboid barrel, and arrange the movable plate with multiple rows of holes facing upward first. Do not install, transfer liquid C into the assembled cuboid barrel, cover the movable plate with multi-arranged holes facing upwards, transfer it to the vacuum box, and carry out gel setting under intermittent vacuum. The intermittent vacuum parameters are as follows: v...

Embodiment 2

[0041] The preparation method of the gel diaphragm for new rare earth power supply comprises the following steps:

[0042] (1) The inorganic electrolyte magnesium lithium silicate, CMC and H 2 O, configured according to the mass ratio of 6:4:90, marked as liquid A; four kinds of high molecular polymers PVA, PAAS, PAA, and PFO are mixed, and the mass ratio is 1:1:1:1. The mixed high molecular polymer with H 2 O is configured according to the mass ratio of 10:90, marked as liquid B;

[0043] (2) According to the mass ratio of liquid A and liquid B of 1:3, liquid A is added to liquid B and stirred evenly to form liquid C; assemble the detachable movable plate into a cuboid barrel, and arrange the movable plate with multiple rows of holes facing upward first. Do not install, transfer the C liquid into the assembled cuboid barrel, cover the movable plate with multi-arranged holes facing upwards, transfer it to the vacuum box, and carry out the gel setting under intermittent vacuu...

Embodiment 3

[0047] The preparation method of the gel diaphragm for new rare earth power supply comprises the following steps:

[0048] (1) The inorganic electrolyte magnesium lithium silicate, CMC and H 2 O, configured according to the mass ratio of 8:5:87, marked as liquid A; high molecular polymer PAAK and H 2 O is configured according to the mass ratio of 8:92, marked as liquid B;

[0049] (2) According to the mass ratio of liquid A and liquid B of 1:2, add liquid A to liquid B and stir evenly to form liquid C; assemble the detachable movable plate into a cuboid barrel, and arrange the movable plate with multiple rows of holes facing upward first. Do not install, transfer liquid C into the assembled cuboid barrel, cover the movable plate with multi-arranged holes facing upwards, transfer it to the vacuum box, and carry out gel setting under intermittent vacuum. The intermittent vacuum parameters are as follows: vacuum is 2.2× 10 -3 Pa, the temperature is 55°C; after the first vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com