Preparation method of positive electrode material of lithium ion battery and product thereof

A lithium-ion battery and positive electrode material technology, applied in the field of electrochemical batteries, can solve the problems of unfavorable industrial production and complicated process, and achieve the effects of improving specific capacity and cycle stability, being environmentally friendly, and slowing down the generation of intergranular cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of lithium ion battery cathode material comprises the following steps:

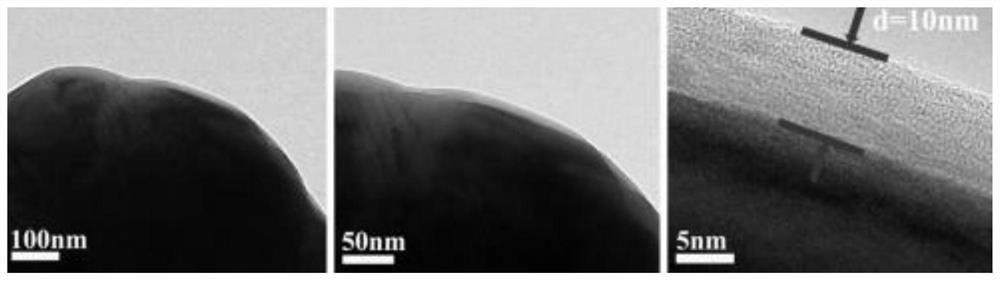

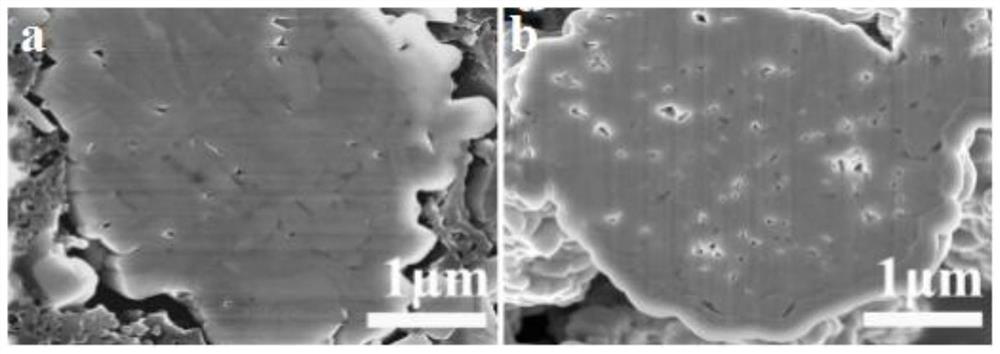

[0035] Weigh LiNi according to the mass ratio of 1:0.03 0.5 co 0.2 mn 0.3 o 2 ,MoS 2 , mix evenly, place in a mixing granulator, adjust the power to 5KW, react for 5 minutes, take it out and place it in an atmosphere furnace, sinter in an air atmosphere at 350°C for 7h, and cool naturally to room temperature to obtain the lithium-ion battery Cathode material, its transmission electron microscope picture is as follows figure 1 shown.

[0036]Battery production and testing: Weigh 0.8g of the lithium-ion battery cathode material prepared above, add 0.1g of acetylene black, 0.1g of PVDF dissolved in N-N dimethyl pyrrolidone polyvinylidene fluoride binder , mixed uniformly to form a slurry, evenly coated on aluminum foil, in an argon atmosphere glove box, with metal lithium sheet as a counter electrode, Celgard2400 as a diaphragm, 1mol / L LIPF6 (EC:DEC:DMC=1:1:1 ) is the electrolyt...

Embodiment 2

[0038] Preparation of cathode materials for lithium-ion batteries:

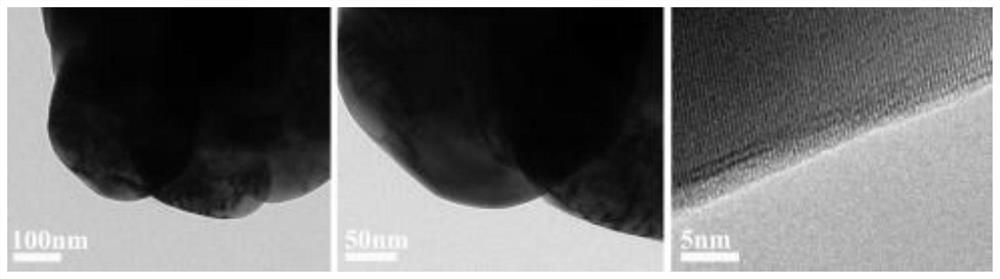

[0039] Weigh Li according to the mass ratio of 1:0.015:0.025 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 、MoS 2 and NaNbO 3 , mix evenly, place in a mixing granulator, adjust the power to 3KW, react for 7 minutes, take it out and place it in an atmosphere furnace, sinter at 450°C for 3h in an oxygen-enriched atmosphere (oxygen volume fraction is 30%), and cool naturally to At room temperature, the positive electrode material for the lithium ion battery is obtained.

[0040] The manufacturing and testing methods of the battery are the same as those in Example 1, except that the voltage range during testing is 2.0V-4.8V.

Embodiment 3

[0042] Weigh Li according to the mass ratio of 1:0.06 1.2 mn 0.6 Ni 0.2 o 2 and NaNbO 3 , mix evenly, place in a mixing granulator, adjust the power to 1KW, react for 12 minutes, take it out and place it in an atmosphere furnace, and sinter at 500°C for 2 hours in an oxygen-enriched atmosphere (oxygen volume fraction is 30%), and cool naturally to At room temperature, the positive electrode material for the lithium ion battery is obtained.

[0043] The manufacturing and testing methods of the battery are the same as those in Example 1, except that the voltage range during testing is 2.0V-4.8V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com