Multilayer hollow Nano fiber in use for cell culture, and preparation method

A technology for culturing nanofibers and cells, applied in tissue cell/virus culture devices, biochemical equipment and methods, chemical instruments and methods, etc., can solve problems such as multi-layer hollow nanofibers that have not been reported, and achieve free choice of components, The effect of simple preparation device, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

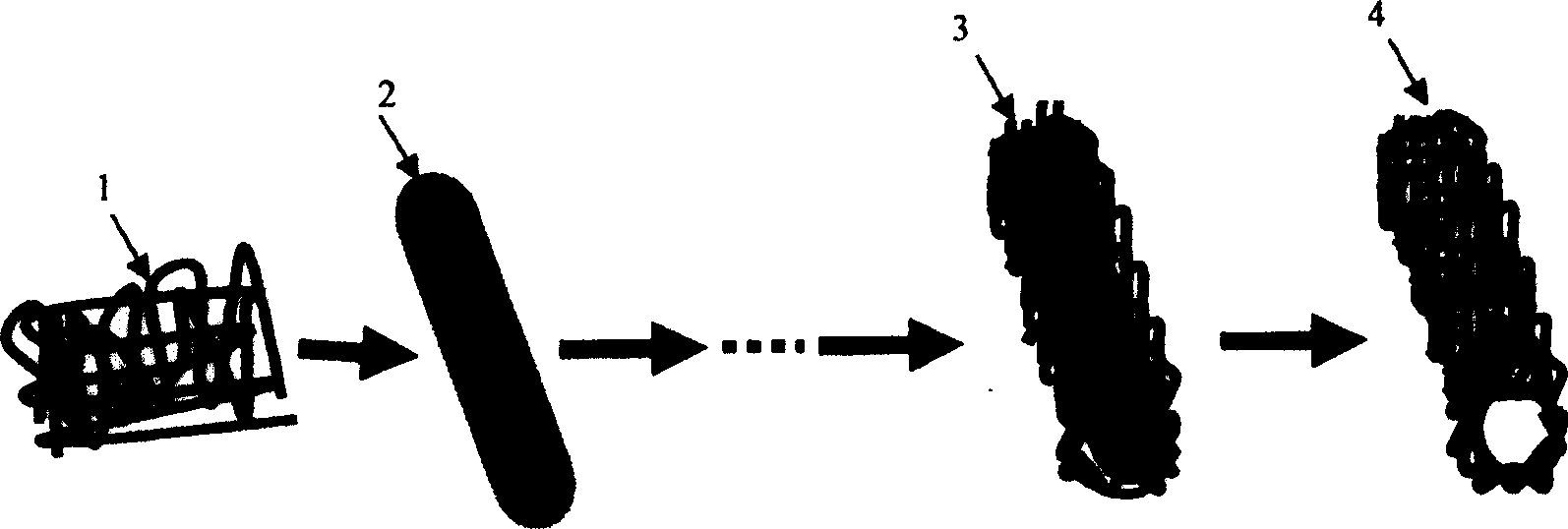

[0029] The preparation method is to dissolve water-soluble polyelectrolyte: sodium polystyrene sulfonate and polyaminoallyl hydrochloride in water, and then assemble it layer by layer on the surface of nano electrospun fibers. The specific steps are as follows:

[0030] 1) Water is used as a solvent to configure positively or negatively charged polyelectrolyte solutions respectively;

[0031] 2) Dip the electrospun polystyrene (PS) fiber into the oppositely charged polyelectrolyte polyaminoallyl hydrochloride solution, rinse with distilled water several times; then dip into the sodium polystyrene sulfonate solution, Multiple layers of polyelectrolytes were assembled on the fiber surface repeatedly.

[0032] 3) Using an organic solvent tetrahydrofuran to selectively remove the internal polystyrene fiber as a template, while the solvent does not damage the external polyelectrolyte, thereby obtaining a multilayer hollow fiber.

[0033] The above-mentioned organic solvent may als...

Embodiment 1

[0034]Example 1: Preparation of (poly(allylaminehydrochloride) (poly(allylaminehydrochloride) (PAH, polycation) / polystyrenesulfonate, sodium salt) (PSS, polyanion) with a size of about 400nm ) 4 Multilayer hollow fiber:

[0035] Preparation of aqueous solution: Polyaminoallyl hydrochloride and sodium polystyrene sulfonate were respectively dissolved in 0.5M sodium chloride aqueous solution to prepare a polyelectrolyte aqueous solution with a concentration of 1.0 mg / ml.

[0036] Template preparation: Polystyrene nanofibers were prepared with an electrospinning spinneret, with a size distribution of 800-1300nm.

[0037] Immerse the negatively charged polystyrene fiber into the polycationic polyaminoallyl hydrochloride solution, so that the surface of the fiber is adsorbed with a layer of polyaminoallyl hydrochloride, so that the surface is positively charged, and the excess polymer is washed away. things. Then immerse the fiber into the sodium polystyrene sulfonate solution, ...

Embodiment 2

[0038] Embodiment 2: use PS fiber as a template, polyaminoallyl hydrochloride solution concentration is 0.5mg / ml, bovine serum albumin aqueous solution concentration is 1.0mg / ml, operation steps are the same as above, and the available size is 400 nanometers Left and right multilayer polyaminoallyl hydrochloride / BSA hollow nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com