Continuous plating device for films and method for performing continuous plating on films

An electroplating device and thin film technology, applied in the field of continuous electroplating devices, achieves the effects of uniform coating thickness, high operational flexibility, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

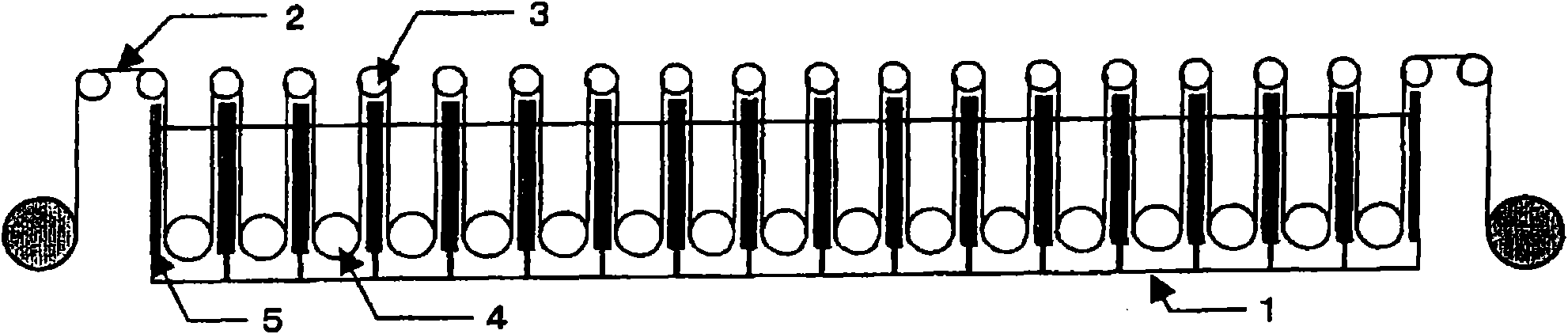

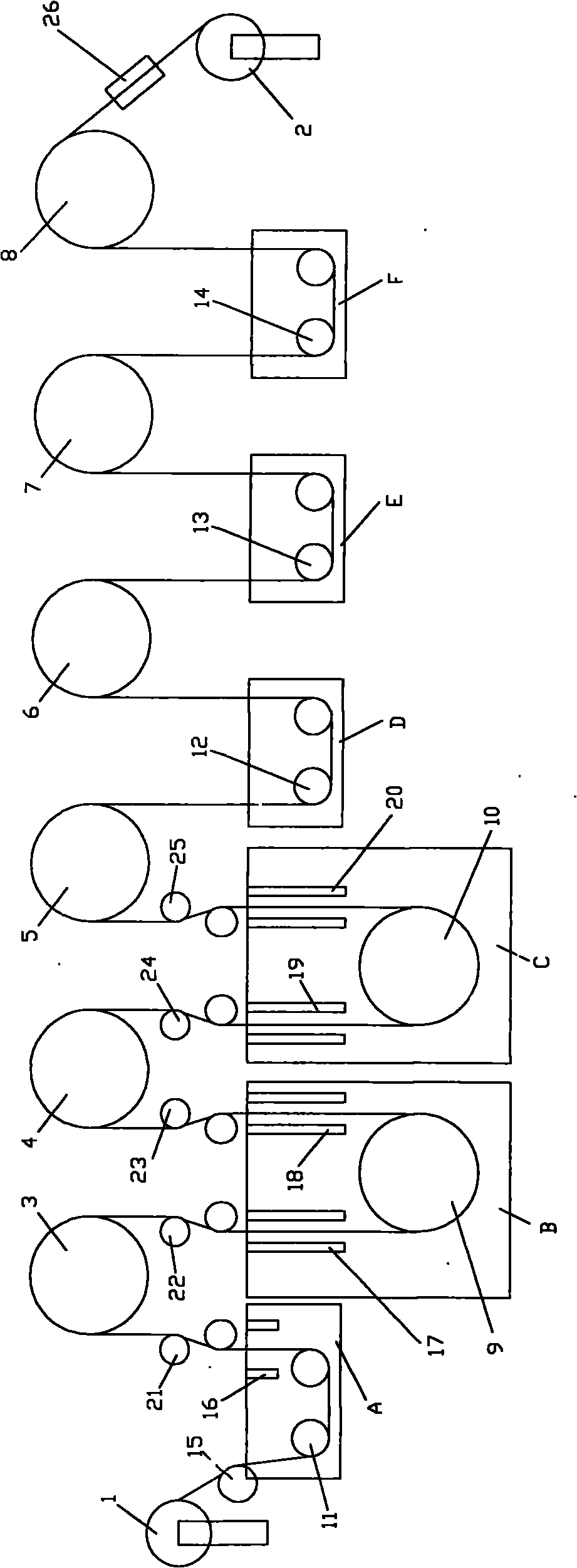

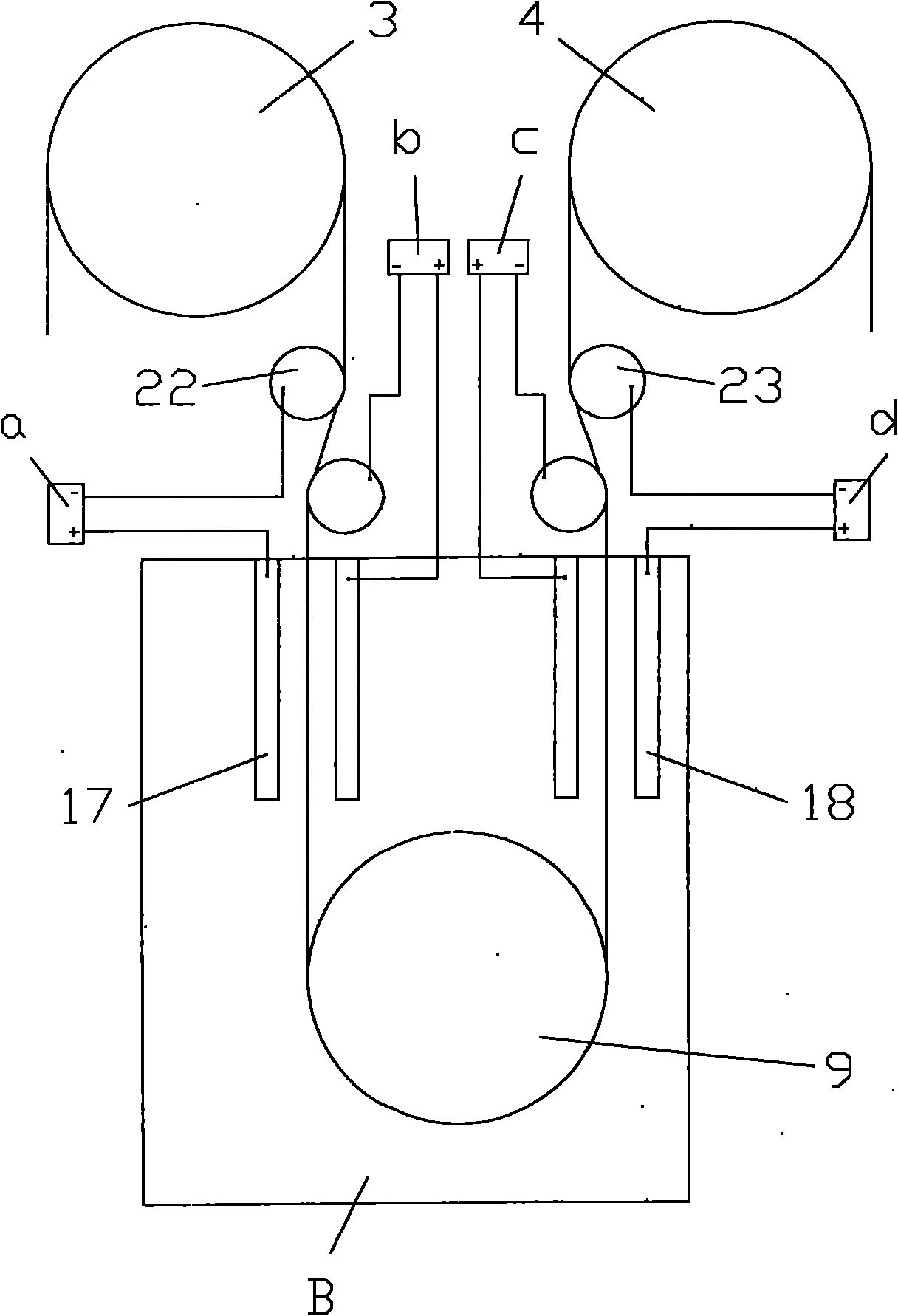

[0060] Example 1 is a continuous electroplating device for thin films provided by a preferred embodiment of the present invention

[0061] like figure 2 As shown, the continuous electroplating device provided by the present invention comprises pre-plating tank A, main electroplating tank B, main electroplating tank C, washing tank D, passivation tank E and washing tank F; unwinding machine 1, winder 2, The fourth guide roller 3, the third guide roller 4, the sixth guide roller 5, the seventh guide roller 6, the seventh guide roller 7, the eighth guide roller 8, the first guide roller 9, the first guide roller group 10, the There is a drying box 26 between the winding machine 2 and the eighth guide roller 8; the second guide roller 11, the fourth guide roller 12, the fourth guide roller 14, the fifth guide roller 13, the third guide roller 15; the second anode Group 16, first anode group 17, first anode group 18, first anode group 19, first anode group 20; second conductive r...

Embodiment 2

[0065] Embodiment 2 is used to illustrate the method that film is carried out continuous electroplating provided by the present invention

[0066] Adopt the continuous electroplating device that embodiment 1 provides to carry out, and thin film is the polyimide (PI) thin film that double-sided coating 50 nanometer copper film; 15 Amps / dm 2 , the pre-plating solution is: copper sulfate 60 g / L, sulfuric acid 100 g / L, hydrochloric acid 0.2 mL / L, Atotech 210 cylinder opening agent 10 mL / L, Atotech 210A: 0.8 mL / L, Atotech 210B: 0.6 mL / L. In the main electroplating tank, the temperature of the electroplating solution is 25°C, and the average cathode current density is 3.9 amperes / dm 2 , the plating solution includes copper sulfate 60 g / L, sulfuric acid 100 g / L, hydrochloric acid 0.15 mL / L, and Atotech 210 cylinder opening agent 10 mL / L, Atotech 210A: 0.8 mL / L, Atotech 210B: 0.6 mL / L. The film runs at a speed of 10 m / h.

[0067] After electroplating, wash the film through a wash...

Embodiment 3

[0069] Embodiment 3 is used to illustrate the method that film is carried out continuous electroplating provided by the present invention

[0070] Adopt the continuous electroplating device that embodiment 1 provides to carry out, and thin film is the polyimide (PI) thin film that double-sided coating 50 nanometer copper film; 20 Amps / dm 2 , the pre-plating solution is copper sulfate 100 g / L, sulfuric acid 150 g / L, hydrochloric acid 0.2 mL / L, cylinder opening agent 10 mL / L, Atotech 210A: 0.8 mL / L, Atotech 210B: 0.6 mL / L. In the main electroplating tank, the temperature of the electroplating solution is 28°C, and the average cathode current density is 12 amperes / dm 2 , the plating solution includes copper sulfate 80 g / L, sulfuric acid 60 g / L, hydrochloric acid 0.15 mL / L, and Atotech 210 cylinder opening agent 10 mL / L, Atotech 210A: 0.8 mL / L, Atotech 210B: 0.6 mL / L. The film runs at a speed of 20 m / h.

[0071] After electroplating, wash the film through a washing tank filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com