Processing Technology of Refractory Metal Wire Gold Plating

A refractory metal and processing technology, which is applied in the field of refractory metal wire gold-plating processing technology, can solve the problems of rough surface, narrow range of cathode current density, uneven distribution of gold ions, etc., to improve anti-oxidation performance and increase surface smoothness The effect of safety and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

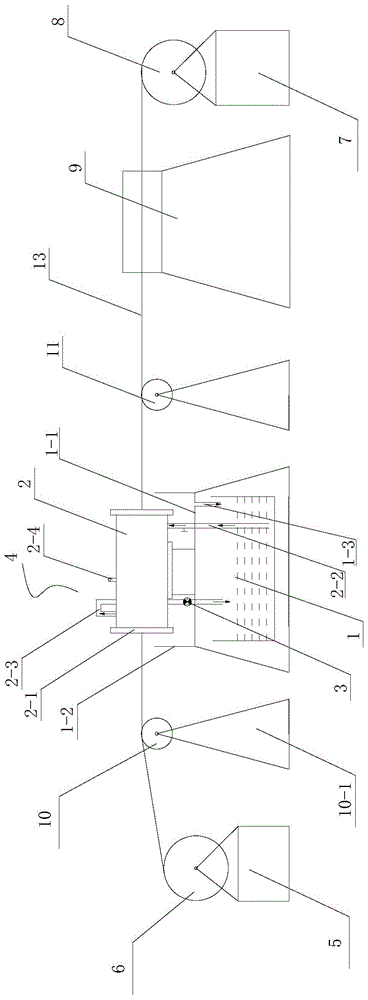

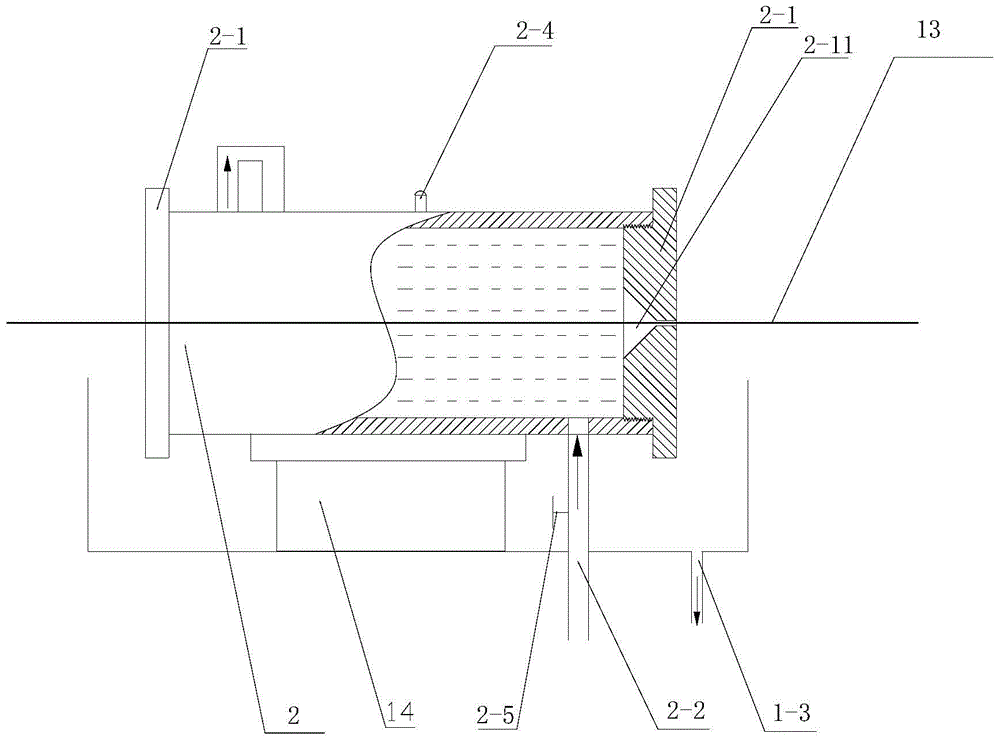

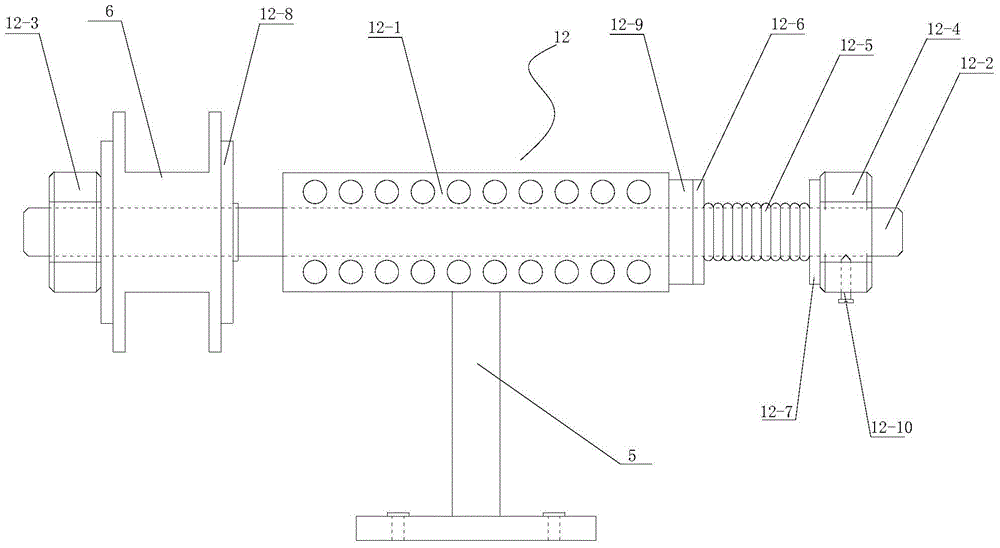

[0034] see Figure 1 to Figure 10 Shown, a kind of refractory metal wire gold-plated processing technology, this processing technology adopts and comprises electroplating solution pool 1, graphite tube 2, self-priming pump 3, pay-off reel 6, take-up reel 8, heating furnace 9, the first The gold plating device of the guide wheel 10, the second guide wheel 11 and the tension adjustment device 12 is equipped with a prepared electroplating solution in the electroplating solution pool 1, and the electroplating solution adopts strong ammonia water or sodium hydroxide to adjust the pH value to 8.5 ~9, the concentrated ammonia water refers to ammonia water with a concentration of 25-28%. The electroplating solution in the electroplating solution pool 1 is sucked into the graphite tube 2 by the self-priming pump 3 to form a circulation, forming an electroplating tank 4 through whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com