Preparation method of coating for melting crucible

A melting crucible and coating technology, applied in the field of coating preparation, can solve the problems of small adhesion between coating and melting crucible, unable to achieve the effect of coating, complicated process, etc. Adhesion-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

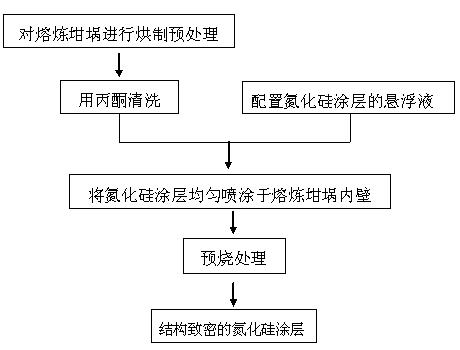

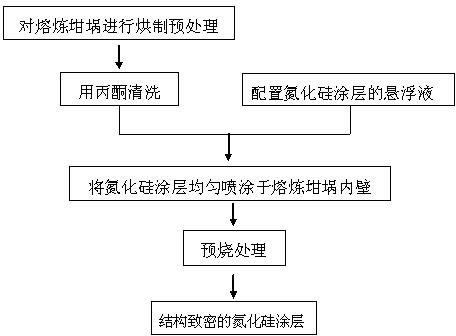

Image

Examples

Embodiment 1

[0021] The first step of baking pretreatment: the "three high" graphite crucible is selected as the melt carrier. Due to the long-term placement and the influence of the processing process, the crucible needs to be baked. The baking process is carried out in a directional solidification furnace. Insulate at 800°C for 1 hour at a vacuum of 5 Pa, take out the crucible after the furnace is cooled, and wash with acetone to remove the organic solvent on the inner wall;

[0022] The second step configures the suspension of silicon nitride coating: in the dehydrated ethanol solution of 20g 8wt%PVP, add 30g particle size and be the Si of 100 microns 3 N 4 powder, stir for about 2 hours to disperse the powder as evenly as possible, and let it stand for use;

[0023] The third step is to spray the coating: connect the cleaned spray gun to the air outlet of the air compressor, adjust the air pressure to 500Pa, first use anhydrous ethanol to test spray, and after the whole channel is smo...

Embodiment 2

[0026] The first step of baking pretreatment: choose Al 2 o 3 The crucible is used as the carrier of the melting material. Due to the long-term placement and the influence of the processing process, the crucible needs to be baked. The baking process is carried out in a directional solidification furnace. After cooling, take out the crucible and wash it with acetone to remove the organic solvent on the inner wall;

[0027] The second step configures the suspension of silicon nitride coating: in the dehydrated ethanol solution of 10g 6wt%PVP, add 20g particle size and be the Si of 130 microns 3 N 4 powder, stir for about 2 hours to disperse the powder as evenly as possible, and let it stand for use;

[0028] The third step is to spray the coating: connect the cleaned spray gun to the air outlet of the air compressor, adjust the air pressure to 300Pa, first use anhydrous ethanol to test spray, and after the whole channel is smooth, put the static Si 3 N 4 The supernatant of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com