High-conductivity amorphous soft magnetic coating

An amorphous layer, highly conductive technology, used in coatings, metal material coating processes, circuits, etc., can solve the problems of lack of conductive magnetic amorphous materials, narrow frequency band, and unsatisfactory low-frequency magnetic shielding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In the present embodiment, the preferred amorphous alloy powder is iron-based amorphous alloy powder, and the specific composition is (Fe 0.76 Si 0.09 B 0.1 P 0.05 ) 99 Nb 1 .

[0057] The preparation method of the iron-based amorphous alloy powder material is as follows:

[0058] (1) The industrial-grade raw materials are prepared according to the required atomic percentage in the composition, and a master alloy ingot with a uniform composition is prepared by using a vacuum induction furnace.

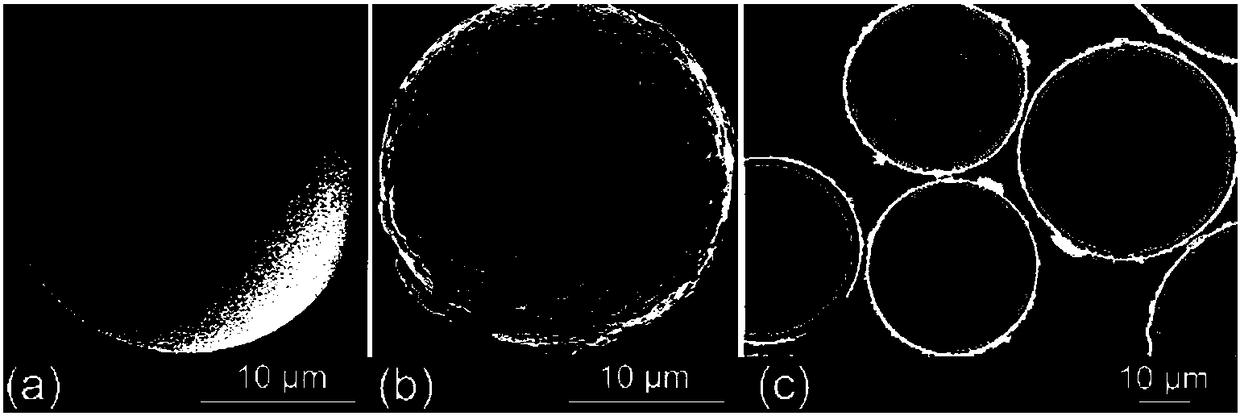

[0059] (2) The obtained master alloy ingot is ground with a grinding wheel to remove surface impurities, and then placed in a multi-stage gas atomization device to obtain iron-based amorphous alloy powder. The scanning electron microscope picture of the above-mentioned amorphous alloy powder is as follows figure 1 As shown in (a), the powder has high sphericity, smooth surface and good fluidity. In the present invention, the particle size range is preferably 10 to 25 μm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com