Highly corrosion-resistant ceramic coating solution prepared through magnesium alloy surface micro-arc oxidation and application thereof

A technology of micro-arc oxidation and ceramic coating, which is applied in anodic oxidation and other directions, can solve the problems of large melting pits on the surface of magnesium alloys and rough ceramic coatings, and achieve the effects of uniform thickness, simple composition and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition of the high corrosion resistance ceramic coating solution prepared by micro-arc oxidation on the surface of magnesium alloy is as follows:

[0036] 12 g / L Potassium Fluozirconate, 10 g / L Ammonium Dihydrogen Phosphate, 2 g / L Potassium Fluoride, 10 g / L Sodium Citrate and the balance of water; the sample is AM60 die-cast magnesium alloy. The micro-arc oxidation power supply adopts a constant voltage pulse power supply, and the parameters are 400V voltage, 100Hz frequency, and 60% duty cycle. The method for preparing a single-layer ceramic coating is:

[0037] 1) Mechanical pretreatment and degreasing treatment;

[0038] Among the present invention, described mechanical pretreatment refers to that sample is ground with sandblasting or sandpaper, removes burr, surface oxide etc.; 1. Wash with 15 g / L sodium carbonate compound aqueous solution to remove general dirt, sintered lubricant, cutting agent, etc., the temperature is controlled at 70 ° C, and the tim...

Embodiment 2

[0046] The composition of the high corrosion resistance ceramic coating solution prepared by micro-arc oxidation on the surface of magnesium alloy is as follows:

[0047] 6 g / L sodium fluozirconate, 8 g / L sodium dihydrogen phosphate, 8 g / L ammonium fluoride, 2 g / L potassium citrate and the balance of water; the sample is AZ31 extruded magnesium alloy. The micro-arc oxidation power supply adopts a constant voltage pulse power supply, and the parameters are 350V voltage, 500Hz frequency, and 20% duty cycle. Its preparation method is identical with embodiment 1.

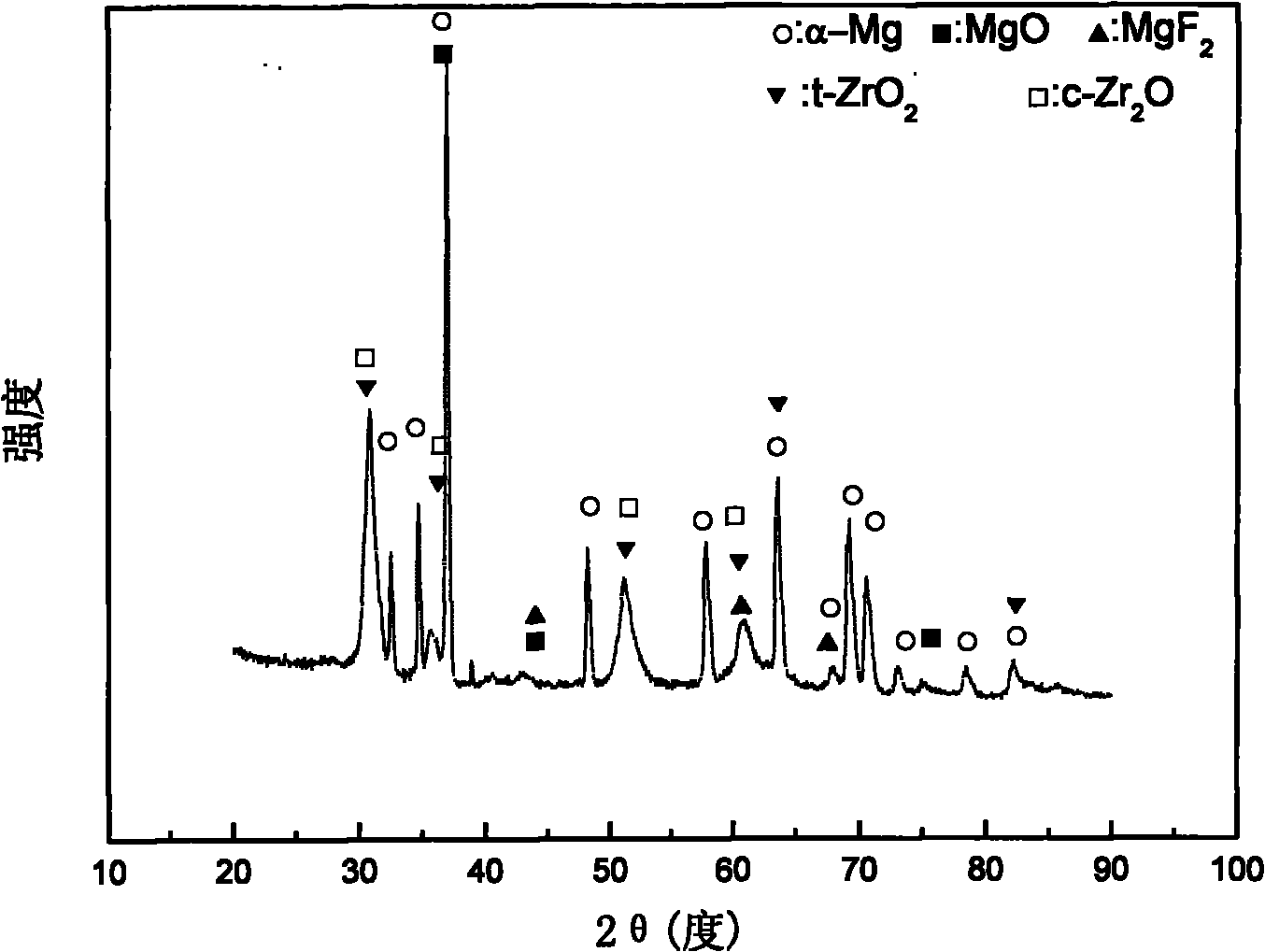

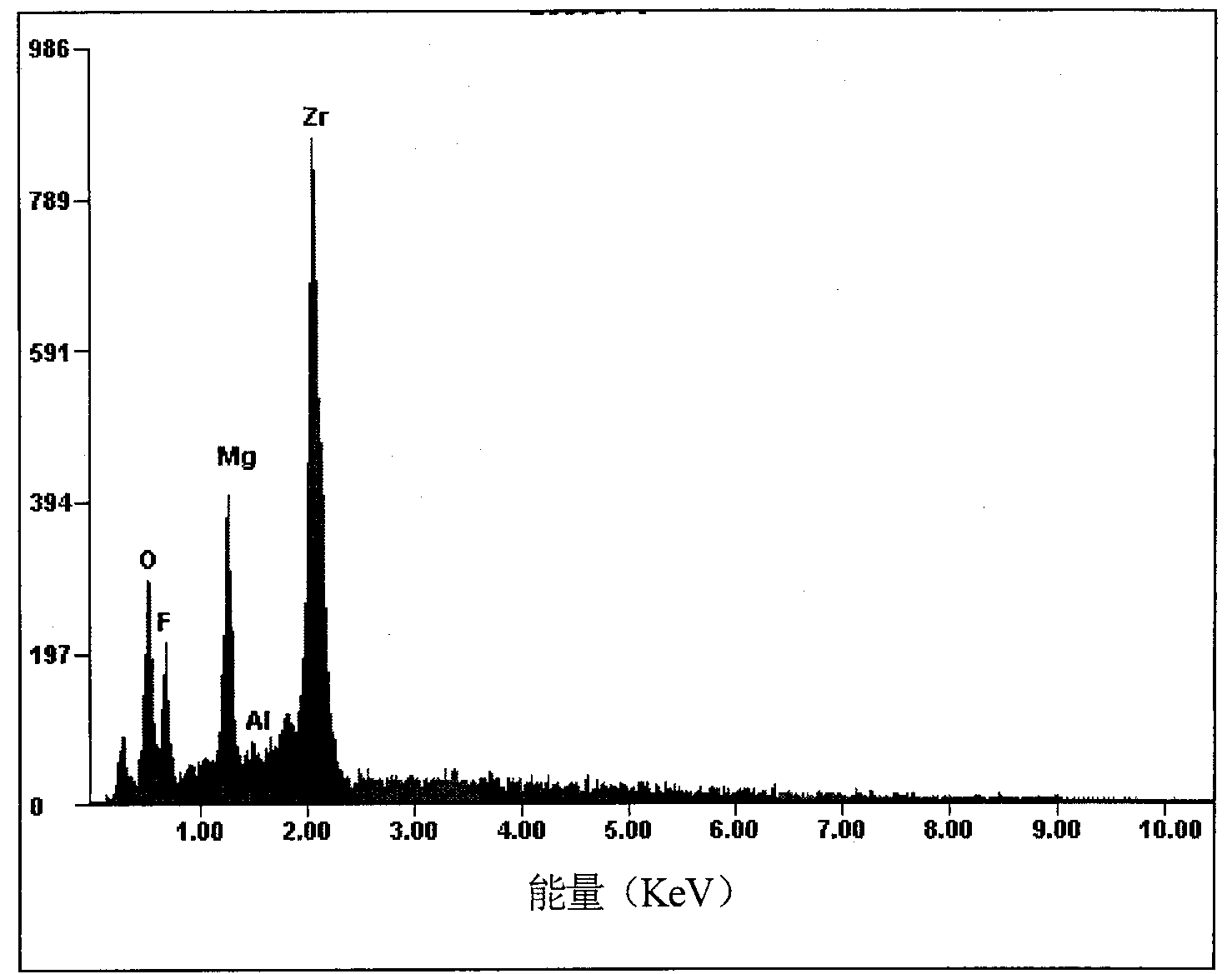

[0048] In this example, the thickness of the ceramic coating is 12.5 μm, and the element composition of the coating is as follows: Zr, Mg, O, F, Al, and the phase structure mainly includes c-Zr 2 O, t-ZrO 2 , MgF 2 , MgO.

[0049] In this embodiment, the performance parameters of the ceramic coating are as follows: the roughness of the film layer is Ra value 0.88 μm, and no pitting occurs in the full immersion test ...

Embodiment 3

[0051] The composition of the high corrosion resistance ceramic coating solution prepared by micro-arc oxidation on the surface of magnesium alloy is as follows:

[0052] 6 g / L sodium fluozirconate, 10 g / L potassium dihydrogen phosphate, 2 g / L sodium fluoride, 6 g / L potassium sodium citrate and the balance of water; the sample is AM50 die-cast magnesium alloy. The micro-arc oxidation power supply adopts a constant voltage pulse power supply, and the parameters are 390V voltage, 1000Hz frequency, and 60% duty cycle. Its preparation method is identical with embodiment 1.

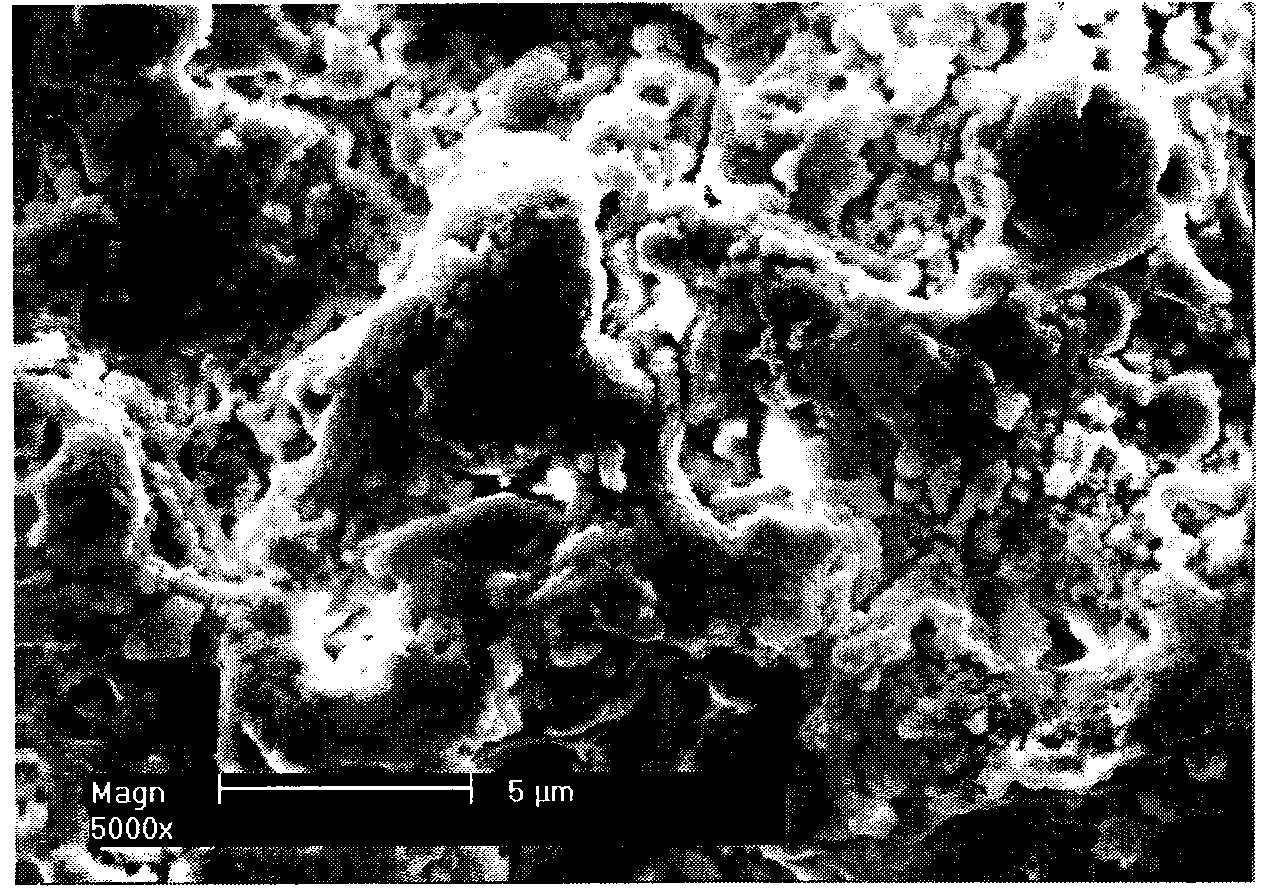

[0053] In this example, the thickness of the ceramic coating is 12.1 μm, and the element composition of the coating is as follows: Zr, Mg, O, F, Al, and the phase structure mainly includes c-Zr 2 O, t-ZrO 2 , MgF 2 , MgO( figure 2 , image 3 ,Table 1).

[0054]Table 1

[0055]

[0056]

[0057] Table 1 is with figure 2 The corresponding data, by figure 2 , image 3 It can be seen from Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com