A process method and device for manufacturing polymer ceramic pipeline lining

A technology of polymer ceramic and process method, which is applied in the field of technology and device for manufacturing polymer ceramic pipeline lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

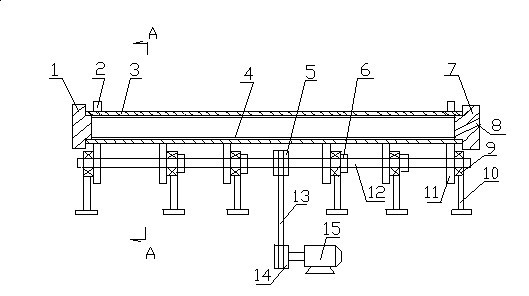

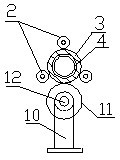

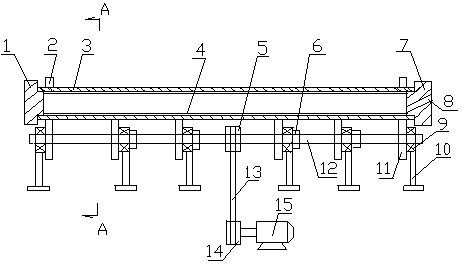

[0022] Example 1, the silica powder with a weight ratio of 80% and a fineness of 200-500 meshes is first mixed with polyamide in a container with a weight ratio of 2%, and then placed in the container within 5 minutes before making the lining. Add epoxy resin powder with a weight ratio of 18% to the mixture and stir and mix it for three minutes to form an enamel paint. Calculate the amount of enamel paint added according to the length, thickness and specific gravity of the inner lining 4. The pipeline is assembled on six driving wheels 11 arranged at intervals. , first seal and fix one end of the pipeline 3 with the left sealing head 1, then add a certain amount of varnish into the pipeline through the feeding hole 8 on the right sealing head 7 within a specified time, and then seal the two ends of the pipeline, the length of the pipeline is 9.6 meters, the inner diameter of the pipeline is 62 mm, and there are two adjustable limit wheels 2 that are symmetrically arranged aroun...

Embodiment 2

[0023] Example 2, the aluminum oxide powder with a weight ratio of 86% and a fineness of 1000-2500 meshes is pre-mixed with ethylenediamine in a container with a weight ratio of 0.3%, and then within 5 minutes before making the lining Add phenolic resin powder with a weight ratio of 13.7% and molybdenum sulfide of 2% of the total weight of the above three raw materials into the container and mix them thoroughly for three minutes to form an enamel paint. Calculate the amount of enamel paint added according to the length, thickness and specific gravity of the inner lining. The pipeline The length is 10 meters, and the inner diameter of the pipeline is 62 millimeters. The device and manufacturing process described in Example 1 are used to complete the coating, molding and curing of the pipeline lining. After testing, the thickness of the lining is between 1.2 and 1.5 mm (one side), the maximum thickness deviation is 0.3 mm, and the maximum error rate is 0.3 per ten thousand. The c...

Embodiment 3

[0024] Example 3 Pre-mix zirconium silicate with a weight ratio of 72% and a fineness of 600-1000 mesh with 4% diethylenetriamine in a container, and then mix it in the container within 5 minutes before making the inner liner. Add phenolic resin powder with a weight ratio of 14% and silicone oil of 3% of the total weight of the above three raw materials to fully mix for three minutes to form an enamel paint. Calculate the amount of enamel paint added according to the length, thickness and specific gravity of the lining. The length of the pipeline is 9.6 meters. The inner diameter of the pipeline is 62 mm, and the coating, molding and curing of the pipeline lining are completed by using the device and manufacturing process described in Example 1. After testing, the thickness of the lining is between 1.3 and 1.6 mm (one side), the maximum thickness deviation is 0.3 mm, and the maximum error rate is 0.3 per ten thousand. The compressive strength of the lining is 269 MPa, and the V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com