Pulse electrochemical deposition and tissue adjustment processes for nickel plating copper belt

A nickel-plated copper, electrochemical technology, applied in the field of pulsed electrochemical deposition and tissue adjustment process, can solve the problem of unfavorable bending resistance and corrosion resistance of nickel-plated nickel-plated copper strip, unable to meet the requirements of high-performance electronic products, plating The problem of unfavorable bending resistance of nickel-copper strips can achieve the effect of improving comprehensive mechanical properties and physical properties, uniform and fine grain structure, and reducing the probability of hydrogen embrittlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

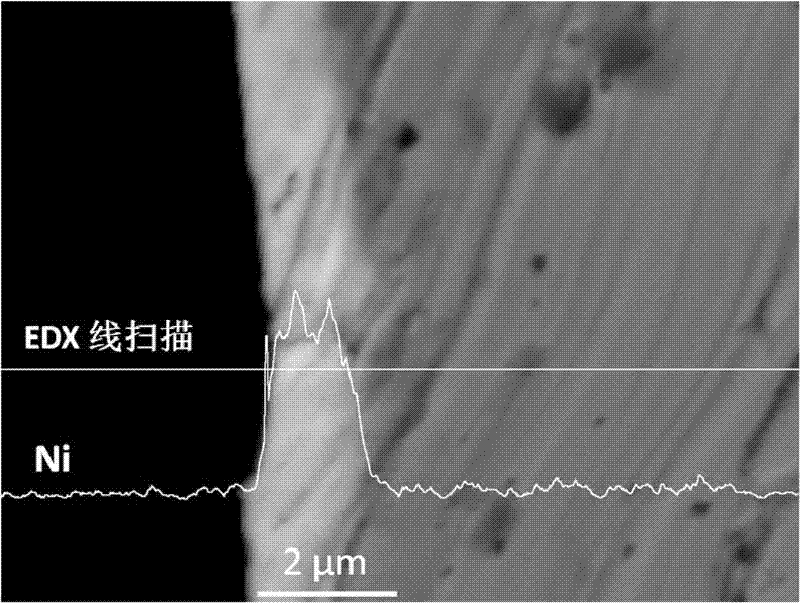

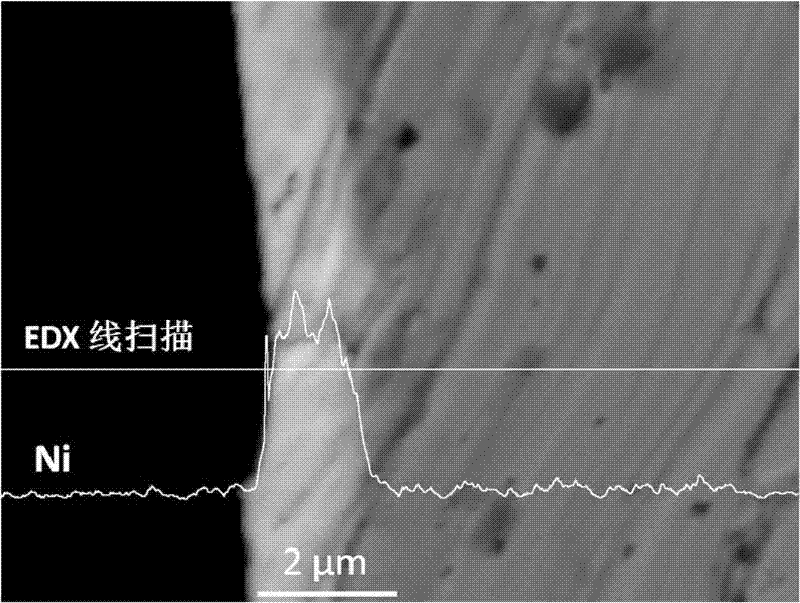

Image

Examples

Embodiment 1

[0022] a) Degreasing the surface of the copper strip: In the lye at a temperature of 50°C, use ultrasonic waves to clean the grease on the surface of the copper strip, then clean it with deionized water and dry it;

[0023] b) Remove the oxide layer on the surface of the copper strip: In a medium-temperature acid solution, the temperature of the acid solution is 40°C, use ultrasonic waves to clean the oxide layer on the surface of the copper strip, then clean it with deionized water and absolute alcohol, and dry it;

[0024] c) Pulse nickel plating: based on Watt’s nickel plating solution, nickel plating is achieved with pulse current, pulse current density J p =30mA / cm 2 , average current density J m =30mA / cm 2 , power-on time range T on 3 ms, power down time range T off 7 milliseconds, change the pulse current application time, the application time is: 5 to 30 minutes;

[0025] d) Vacuum heat treatment: heating the nickel-plated copper strip obtained in step c to 200°C ...

Embodiment 2

[0029] a) Degreasing the surface of the copper strip: In the lye at a temperature of 60°C, use ultrasonic waves to clean the grease on the surface of the copper strip, then clean it with deionized water and dry it;

[0030] b) Remove the oxide layer on the surface of the copper strip: In a medium-temperature acid solution, the temperature of the acid solution is 50°C, use ultrasonic waves to clean the oxide layer on the surface of the copper strip, then clean it with deionized water and absolute alcohol, and dry it;

[0031] c) Pulse nickel plating: based on Watt’s nickel plating solution, nickel plating is achieved with pulse current, pulse current density J p =30mA / cm 2 , average current density J m =30mA / cm 2 , power-on time range T on 3 ms, power down time range T off 7 milliseconds, change the pulse current application time, the application time is: 5 to 30 minutes, control the thickness of the nickel layer;

[0032] d) Vacuum heat treatment: heating the nickel-plate...

Embodiment 3

[0036] a) Degreasing the surface of the copper strip: In the alkali solution at a temperature of 80°C, use ultrasonic waves to clean the grease on the surface of the copper strip, then clean it with deionized water and dry it;

[0037] b) Remove the oxide layer on the surface of the copper strip: In a medium-temperature acid solution, the temperature of the acid solution is 60°C, use ultrasonic waves to clean the oxide layer on the surface of the copper strip, then clean it with deionized water and absolute alcohol, and dry it;

[0038] c) Pulse nickel plating: based on Watt’s nickel plating solution, nickel plating is achieved with pulse current, pulse current density J p =30mA / cm 2 , average current density J m =30mA / cm 2 , power-on time range T on 3 ms, power down time range T off 7 milliseconds, change the pulse current application time, the application time is: 5 to 30 minutes, control the thickness of the nickel layer;

[0039] d) Vacuum heat treatment: heating the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com