Lithium ion battery ceramic diaphragm coated with polyvinylidene fluoride, and preparation method therefor

A polyvinylidene fluoride, lithium-ion battery technology, applied in battery electrodes, battery pack components, separators/films/diaphragms/spacers, etc., can solve the problems of poor flexibility of diaphragms, easy cracking of ceramic slurry, etc. To achieve the effect of improving heat resistance, surface densification and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

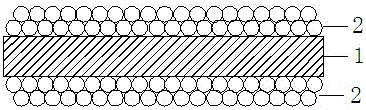

[0028] A lithium-ion battery ceramic diaphragm coated with polyvinylidene fluoride, including a substrate diaphragm, and the two surfaces of the substrate diaphragm are coated with ceramic slurry;

[0029] The lithium-ion battery ceramic separator coated with polyvinylidene fluoride is prepared by the following steps:

[0030] 1. Use polyethylene and polypropylene three-layer composite diaphragm as the substrate, and the substrate diaphragm thickness is 20um. Mix and disperse polyvinylidene fluoride and N-methylpyrrolidone according to the weight ratio of 1:1 to obtain the dispersion glue;

[0031] 2. Mix the dispersion glue with Al 2 o 3 The particles are mixed and dispersed according to the weight ratio of 1:1 to obtain ceramic slurry;

[0032] 3. Use the gravure double-sided coating method to evenly coat the ceramic slurry on the surface of the substrate diaphragm, the coating speed is 25m / min, the coating thickness is 3um, Al 2 o 3 The particle size is 20nm, and dried ...

Embodiment 2

[0034] A lithium-ion battery ceramic diaphragm coated with polyvinylidene fluoride, including a substrate diaphragm, and the two surfaces of the substrate diaphragm are coated with ceramic slurry;

[0035] The lithium-ion battery ceramic separator coated with polyvinylidene fluoride is prepared by the following steps:

[0036] 1. The three-layer composite diaphragm of polyethylene and polypropylene is used as the substrate, and the thickness of the substrate diaphragm is 30um. Polyvinylidene fluoride and N-methylpyrrolidone are mixed and dispersed at a weight ratio of 1:1.5 to obtain a dispersion glue;

[0037] 2. Mix the dispersion glue with Al 2 o 3 The particles are mixed and dispersed according to the weight ratio of 1:2 to obtain ceramic slurry;

[0038] 3. Use the gravure double-sided coating method to evenly coat the ceramic slurry on the surface of the substrate diaphragm, the coating speed is 25m / min, the coating thickness is 3um, Al 2 o 3 The particle size is 20n...

Embodiment 3

[0040] A lithium-ion battery ceramic diaphragm coated with polyvinylidene fluoride, including a substrate diaphragm, and the two surfaces of the substrate diaphragm are coated with ceramic slurry;

[0041] The lithium-ion battery ceramic separator coated with polyvinylidene fluoride is prepared by the following steps:

[0042] 1. Using polyethylene and polypropylene copolymer separator as the substrate, the thickness of the substrate separator is 10um, mix and disperse polyvinylidene fluoride and dimethylacetamide according to the weight ratio of 1:15 to obtain the dispersion glue;

[0043] 2. Mix the dispersion glue with ZrO 2 , ThO 2 The particles are mixed and dispersed at a weight ratio of 1:5 to obtain a ceramic slurry;

[0044] 3. Apply the ceramic slurry evenly on the surface of the substrate diaphragm by gravure single-sided coating, the coating speed is 45m / min, the coating thickness is 7um, ZrO 2 , ThO 2 The particle size is 30nm, and dried at 90°C for 20 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com