Copper-bearing zinc impregnation agent and method for zinc impregnation of metal material

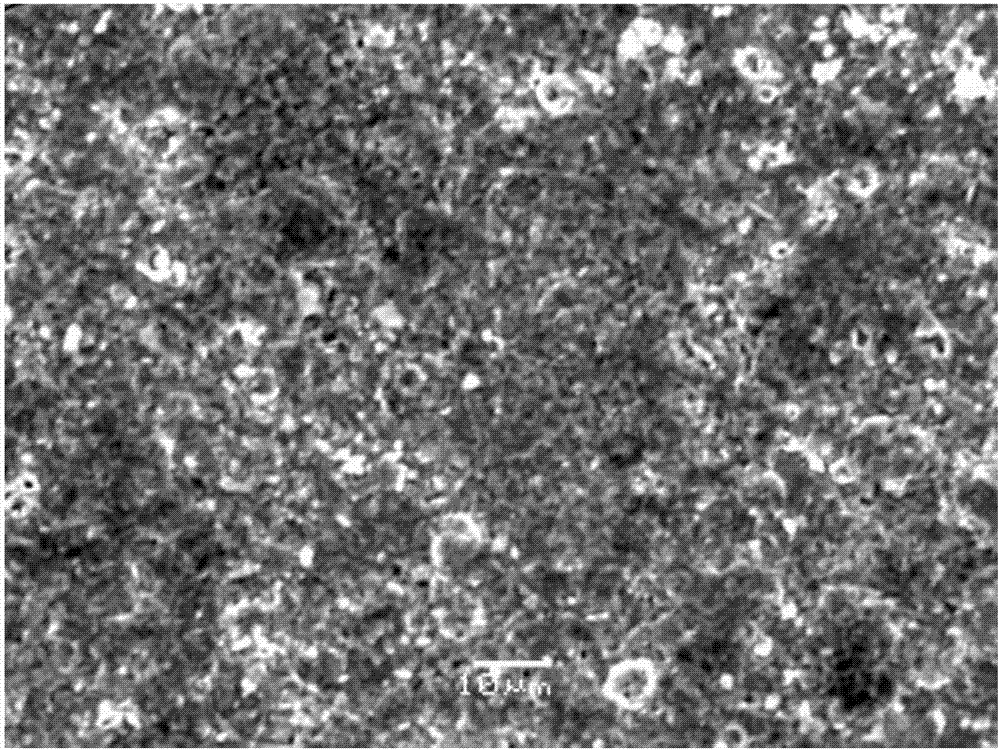

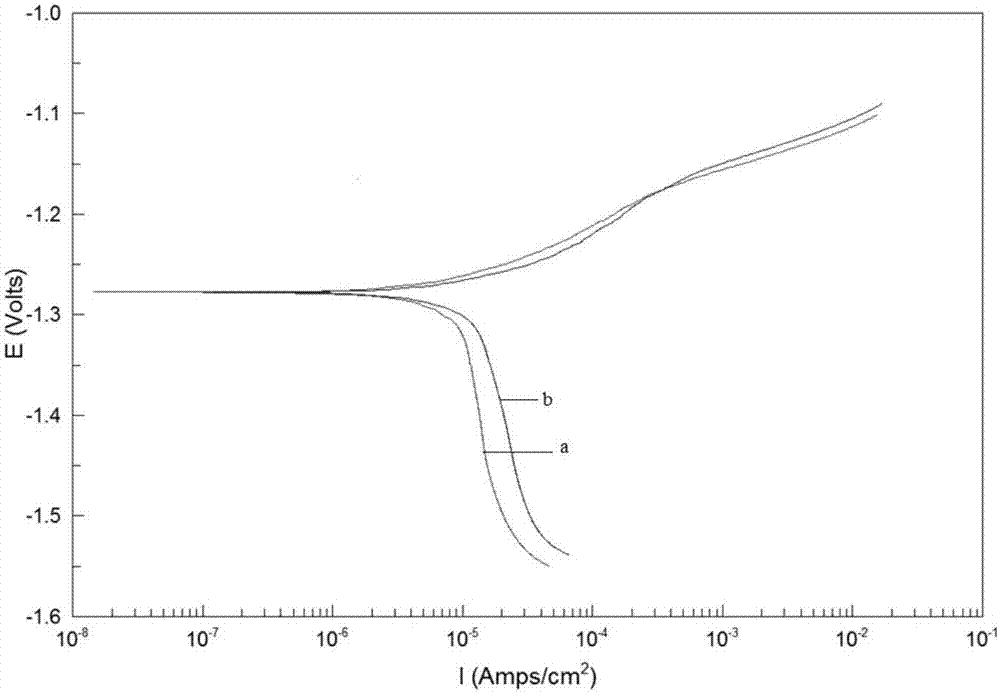

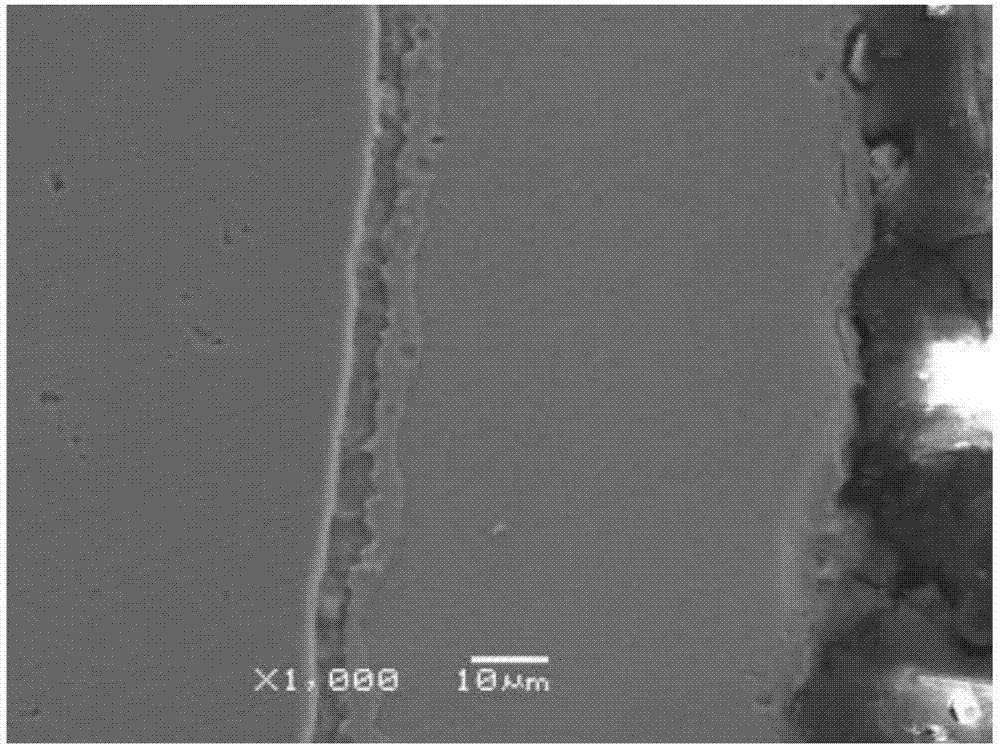

A technology of metal material and zinc shedding, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of corrosion resistance, poor corrosion resistance, poor surface compactness, etc., and improve the surface hardness , Corrosion resistance improvement, the effect of dense penetration layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, weigh 72% of 200-mesh pure zinc powder, 2% of ammonium chloride, 3% of lanthanum nitrate, 21.5% of aluminum oxide, and 1.5% of pure copper powder by mass percentage, the sum of the mass percentages of the above components is 100 %;

[0037] In step 2, the materials in step 1 are uniformly mixed, and ball milled for 1 hour by a horizontal planetary ball mill to obtain the copper-containing zinc-seeding agent.

[0038] Step 3, use wire cutting to obtain a sample with a size of 10*10*3mm, and use sandpaper with a particle size of 280#, 400#, and 600# to grind on a pre-grinder until it is bright.

[0039] In step 4, the sample in step 3 is subjected to pretreatment. That is, alkali washing-water washing-acid washing-water washing-drying for later use.

[0040] Step 5, put the copper-containing zinc-seeding agent obtained in step 2 into a sealed crucible together with the sample, place it in a tubular resistance furnace, heat it up to 455°C with the furnace and kee...

Embodiment 2

[0047] Step 1, weigh 72% of 200-mesh pure zinc powder, 2% of ammonium chloride, 3% of lanthanum nitrate, 21% of aluminum oxide, and 2% of pure copper powder by mass percentage, the sum of the mass percentages of the above components is 100 %;

[0048] In step 2, the materials in step 1 are uniformly mixed, and ball milled for 1 hour by a horizontal planetary ball mill to obtain the copper-containing zinc-seeding agent.

[0049] Step 3, use wire cutting to obtain a sample with a size of 10*10*3mm, and use sandpaper with a particle size of 280#, 400#, and 600# to grind on a pre-grinder until it is bright.

[0050] In step 4, the sample in step 3 is subjected to pretreatment. That is, alkali washing-water washing-acid washing-water washing-drying for later use.

[0051]Step 5, put the copper-containing zinc-seeding agent obtained in step 2 into a sealed crucible together with the sample, place it in a tubular resistance furnace, heat it up to 445°C with the furnace and keep it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com