Electronic water heater

An electronic and magnetic induction water heater technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of complex power amplifier circuits and large magnetic leakage, and achieve the effects of high energy efficiency, powerful functions, and simple and compact circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

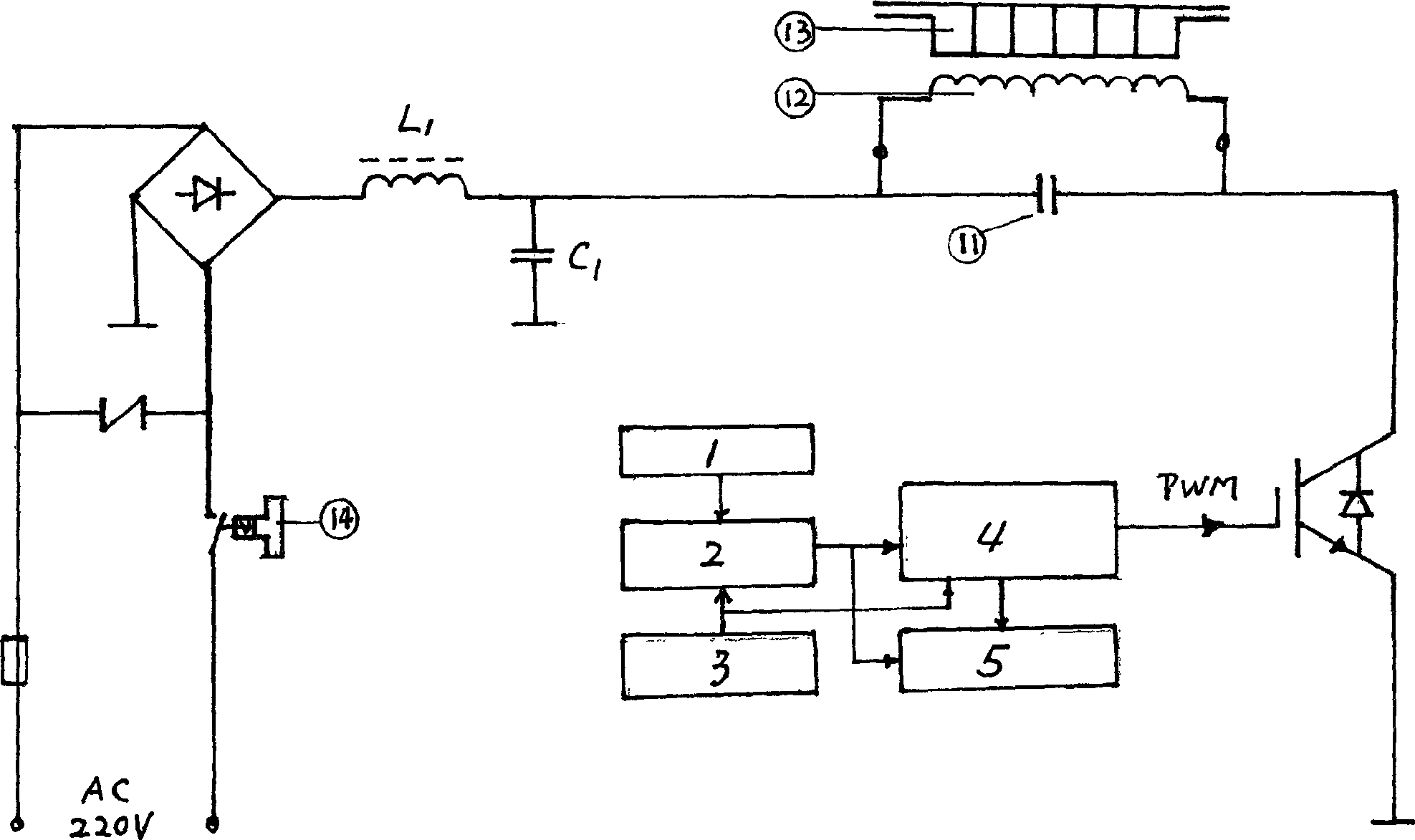

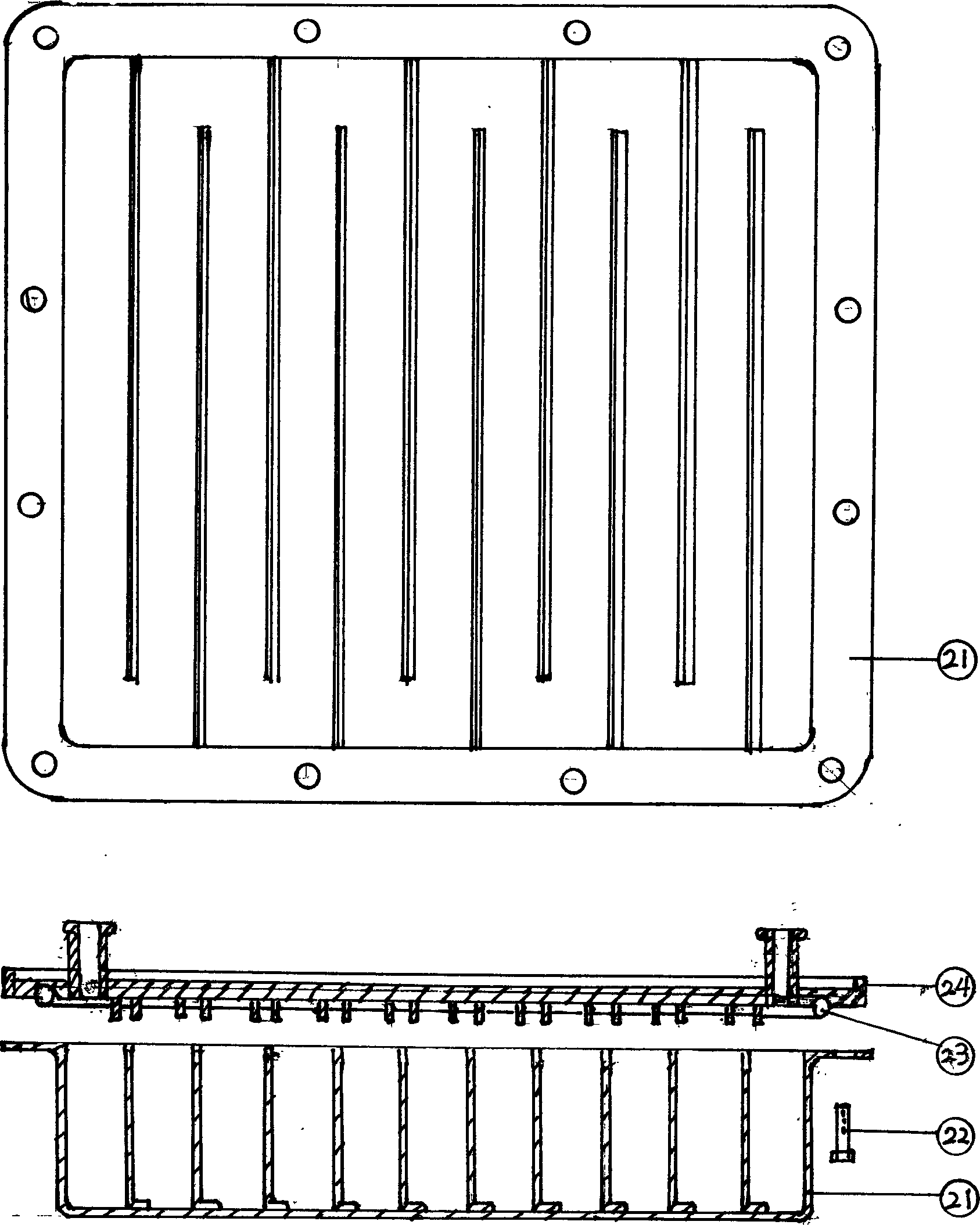

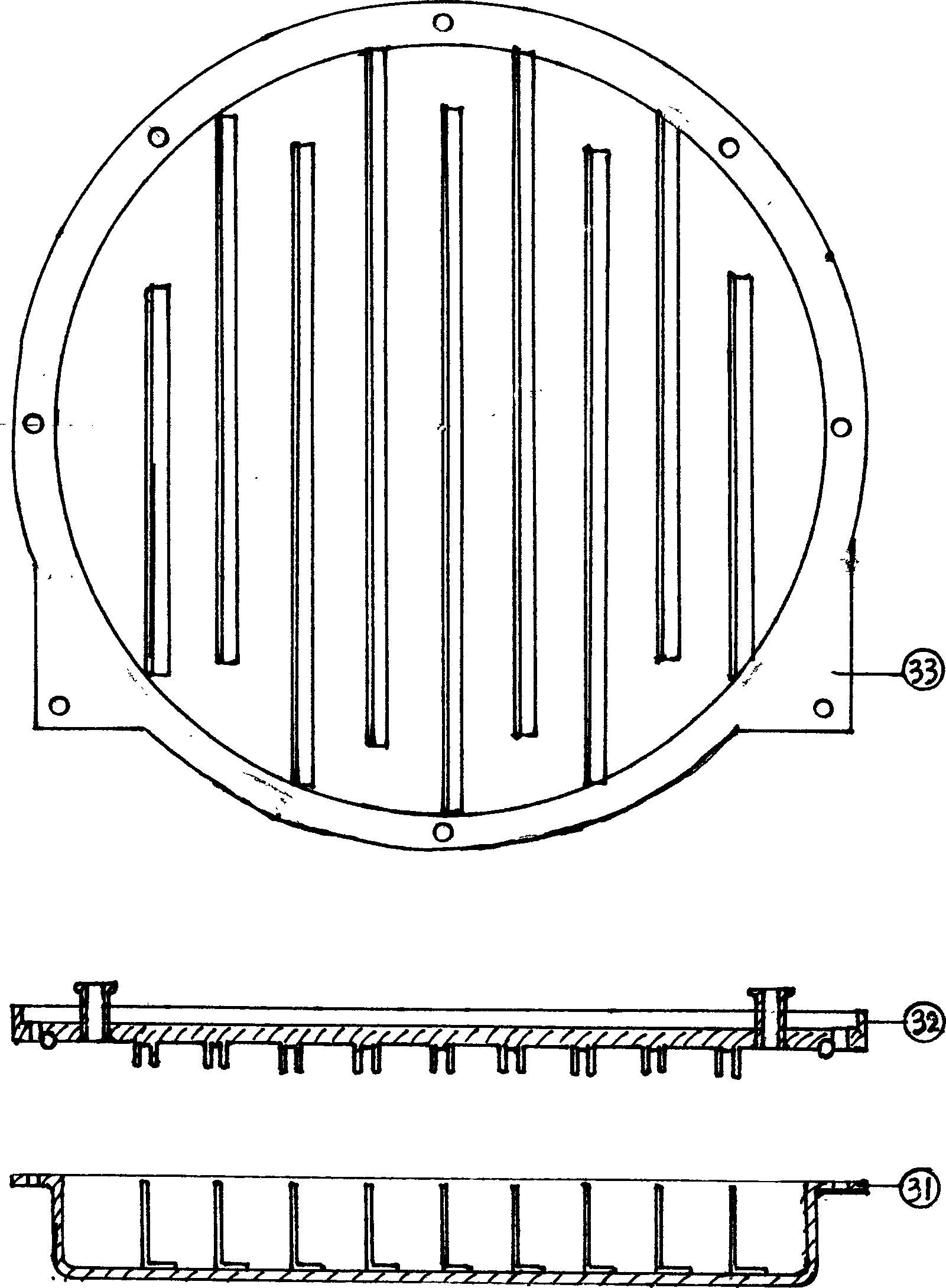

[0033] Refer to attached figure 1 And attached figure 2 or attached image 3 or attached Figure 4. For electronic water heaters, the mains power is controlled by a water pressure switch, and the 300V DC is rectified by the bridge stack to form a circuit through the heating coil and IGBT. Under the control of the PWM switching pulse, the IGBT works with the heating coil and the vibration capacitor connected in parallel, and generates high-frequency alternating current in the heating coil. The bottom of the plate-type heat exchange box, which is relatively close to the insulating assembly of the disc-shaped heating coil, generates a strong eddy current and heats up rapidly, and the electromagnetic energy in the heating coil is converted into heat energy. The water flowing through the groove of the bottom plate of the heat exchange box fully conducts heat exchange with the bottom plate due to the length of the groove, and flows out after the water temperature rises, realizi...

Embodiment 2

[0035] The box cover is changed to a thin metal plate to install the inlet and outlet pipe interface, and the inner side is cushioned with an elastic watertight heat insulation plate and the bottom of the plate box is connected to form a sealed plate heat exchange box with a water tank inside. Then the box is insulated from the heating coil of the electronic frequency converter and tightly assembled together. Place the circuit board on the front and bottom of the heat exchange box, pay attention to the ventilation and heat dissipation of the circuit board, IGBT and heating coil, and the buttons and display screen are in front of the circuit board. The heating coil and heat exchange box are on the upper part of the electric water heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com