Shifting machine suitable for multiple poses of human body

A lift, multi-position technology, applied in the field of lift, can solve the problems of inconvenient operation, many consumables, poor self stability, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

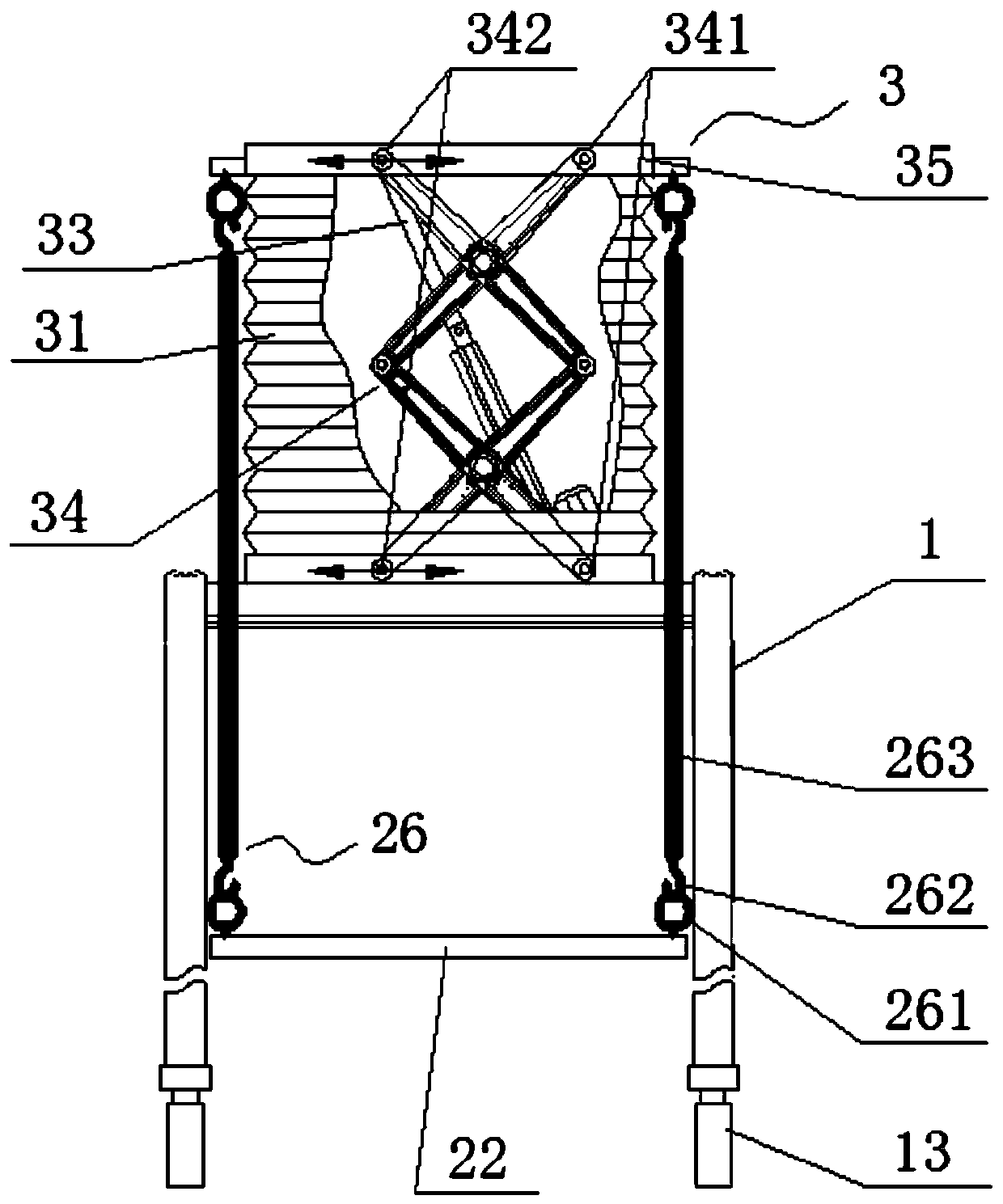

[0053] Such as figure 1 , the human body lifting machine of this embodiment is mainly composed of a mobile frame 1, a scissor lifting mechanism 3, a sling 22 and a sling 26 for carrying a human body.

[0054] The bottom of the mobile frame 1 is provided with castors 13, so that it can be moved more easily. The scissor lift mechanism 3 is arranged on the mobile frame 1 and mainly consists of a scissor lift support 34 and an electric push rod 33 . The lower end of the scissor lift bracket 34 of the present embodiment is the connection end, and the lower end is arranged on the mobile frame 1, and one end of the electric push rod 33 is connected to the scissor lift bracket 34, and the expansion and contraction of the electric push rod makes the upper end of the scissor lift mechanism 3 Lifting occurs, thereby forming a lifting end surface of the lifting end, which is presented in the entity as a lifting end panel 35 arranged on the upper end of the scissor lifting bracket 34 . T...

Embodiment 2

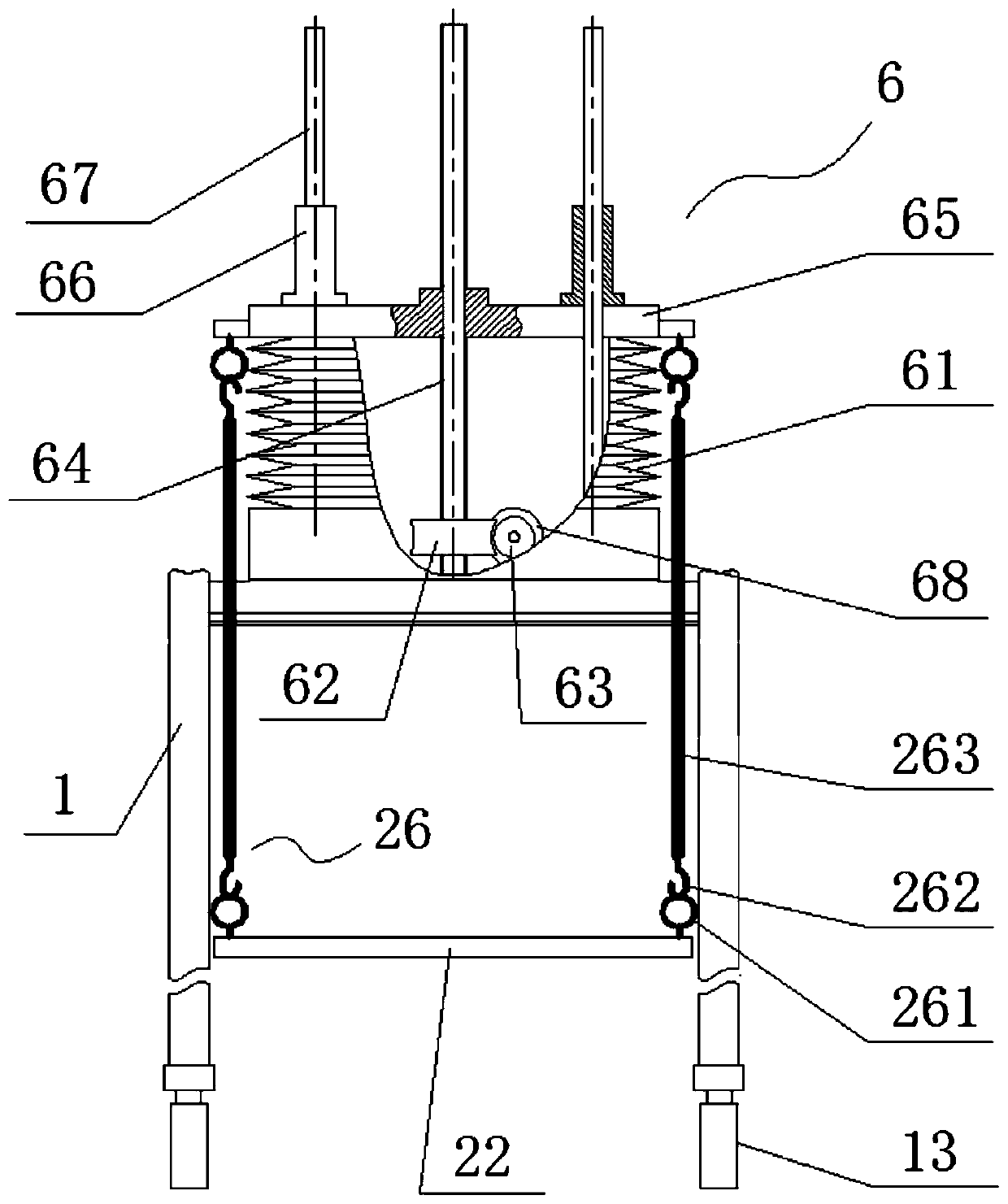

[0058] Such as image 3 , the human body shifting machine of this embodiment is mainly composed of a mobile frame 1, a scissor lift mechanism 3, a sling 22 for carrying a human body, and a sling 26. On the basis of Embodiment 1, the scissor lift mechanism 6 is used to replace the scissor lift mechanism Lifting mechanism.

[0059] Spiral lifting mechanism 6 mainly is made up of screw rod 64, nut 69, turbine 62, worm screw 63, guide rod 67 and guide sleeve 66. The screw rod 64 is rotatably vertically supported on the mobile frame 1, on which a worm gear 62 is connected, and the worm screw 63 is connected on the rotating shaft of the motor 68 and engages the transmission worm gear 62 to make the screw rod rotate. The nut 69 is arranged on the lifting end panel 65, and is composed of a threaded hole designed in the center of the lifting end panel 6. The threaded hole is matched with the screw rod 64. When the screw rod 64 rotates, the lifting end panel is made to rotate through t...

Embodiment 3

[0063] Such as Figure 4 , the body shifting machine of this embodiment is mainly composed of a mobile frame 1, a scissor lifting mechanism 3, a sling 22 for carrying a human body, a sling 26 and a suspension. On the basis of Embodiment 1, a suspension is added. Suspension is the plane frame 21A, and the included plane is much larger than the lifting end face, and it is connected to the lifting end panel 35 that appears as a lifting end face entity, so that the spreader 22 with a larger lifting plane can be hoisted.

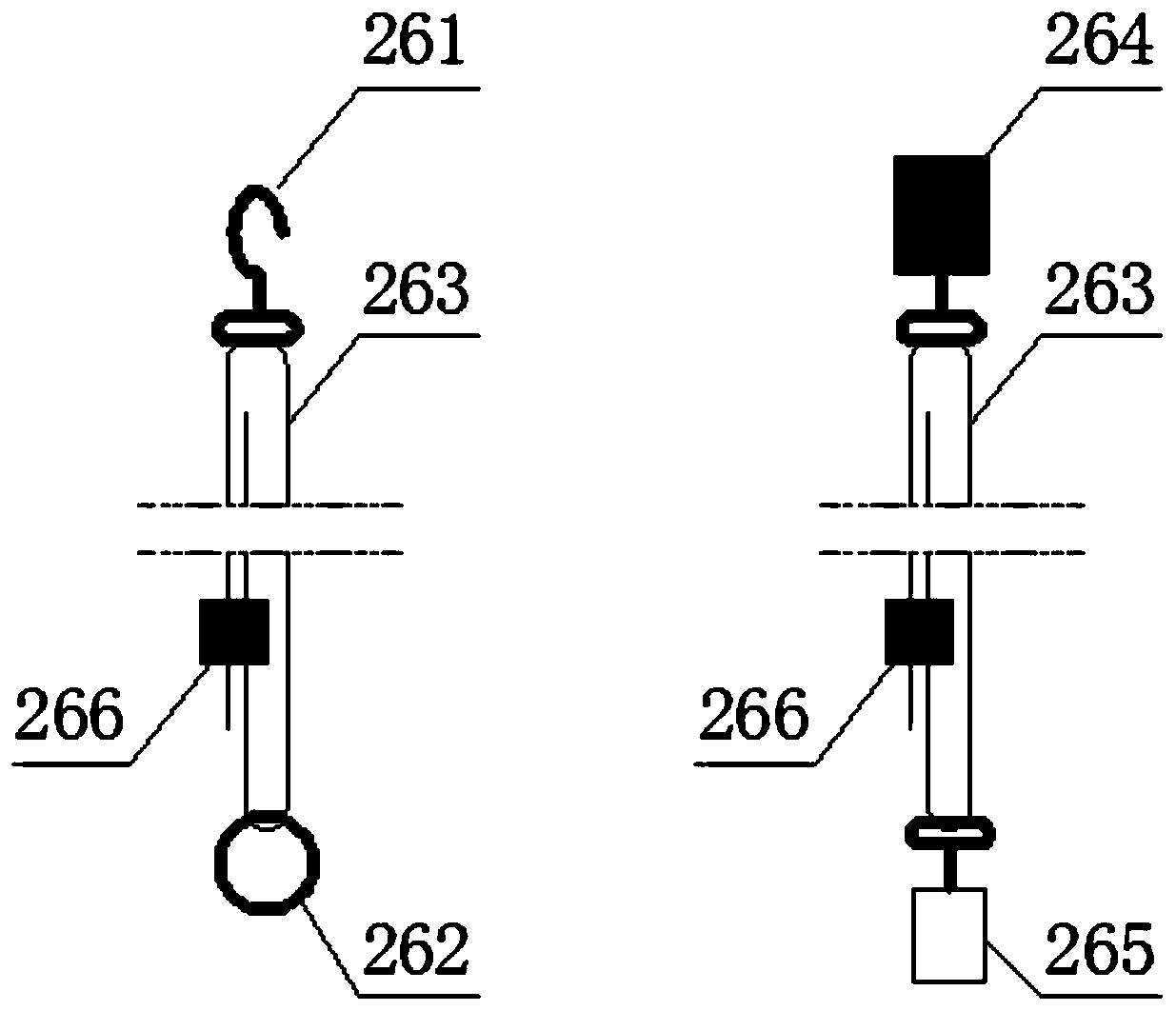

[0064] The planar frame 21A is respectively provided with installation grooves 213 along the sides, and a slider 210 is placed in the installation grooves 213 which can slide along the installation grooves, and the connecting piece is connected to the slider 265 . Such as Figure 5 , 6 , the situation of the connector 264 and the suspension ring 261 on the slider 210 respectively. Through the sliding of the slider in the installation groove, the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com